Castor oil – bean based footwear

What is castor oil?

Castor oil is a non-edible oil extracted from castor beans, also known as Ricinus communis. Ricinus is the Latin word for tick because the seed resembles a tick through its shape and markings. The plant grows wild in varied climatic conditions, in an abundant amount and can survive harsh environments, such as drought and flooding. Castor oil is part of the vegetable oil family which are natures’ renewable resources.

It is mostly produced in the Gujarat region/state in India; the country makes more than 80% of global production in a unique eco-system with more than 700,000 family farming growing castor among other crops. Yearly, India produces around 800,000 tons of castor oil. India is often favored for the extraction process as the country has a labor-intensive cultivation method, which is important for extraction of the seeds. Other producing countries includes China, Brazil, countries in Asia Pacific and South America. The major castor markets are the USA, China, and the EU.

Nowadays the oil is used for many different applications, but its bio-application is seeing increasing interest. It is often used as the basis for producing PU foam, casting resins and adhesives. An important point to note is that even though castor oil produces bio-based materials, these materials are not necessarily biodegradable as the focus might lie on using the materials for a longer lifetime.

Castor plants are usually three to four meters tall and produce spiky fruits with large leaves from August to October. The shell of the fruit resembles those of chestnuts and each fruit contains three seeds, which are known as castor beans.

How does the harvesting work: individuals or machines?

How is the valuable castor oil extracted?

Why is the use of castor oil beneficial for the climate?

In which industries is castor oil used?

Castor oil and the shoe industry

Arkema Rilsan® PA 11 and Pebax® Rnew® TPEs

What changes are needed to make the castor plant more available and user friendly?

Summary

How does the harvesting work: individuals or machines?

For the common varieties of plants, the extraction process requires manually intensive labor .

How is the valuable castor oil extracted?

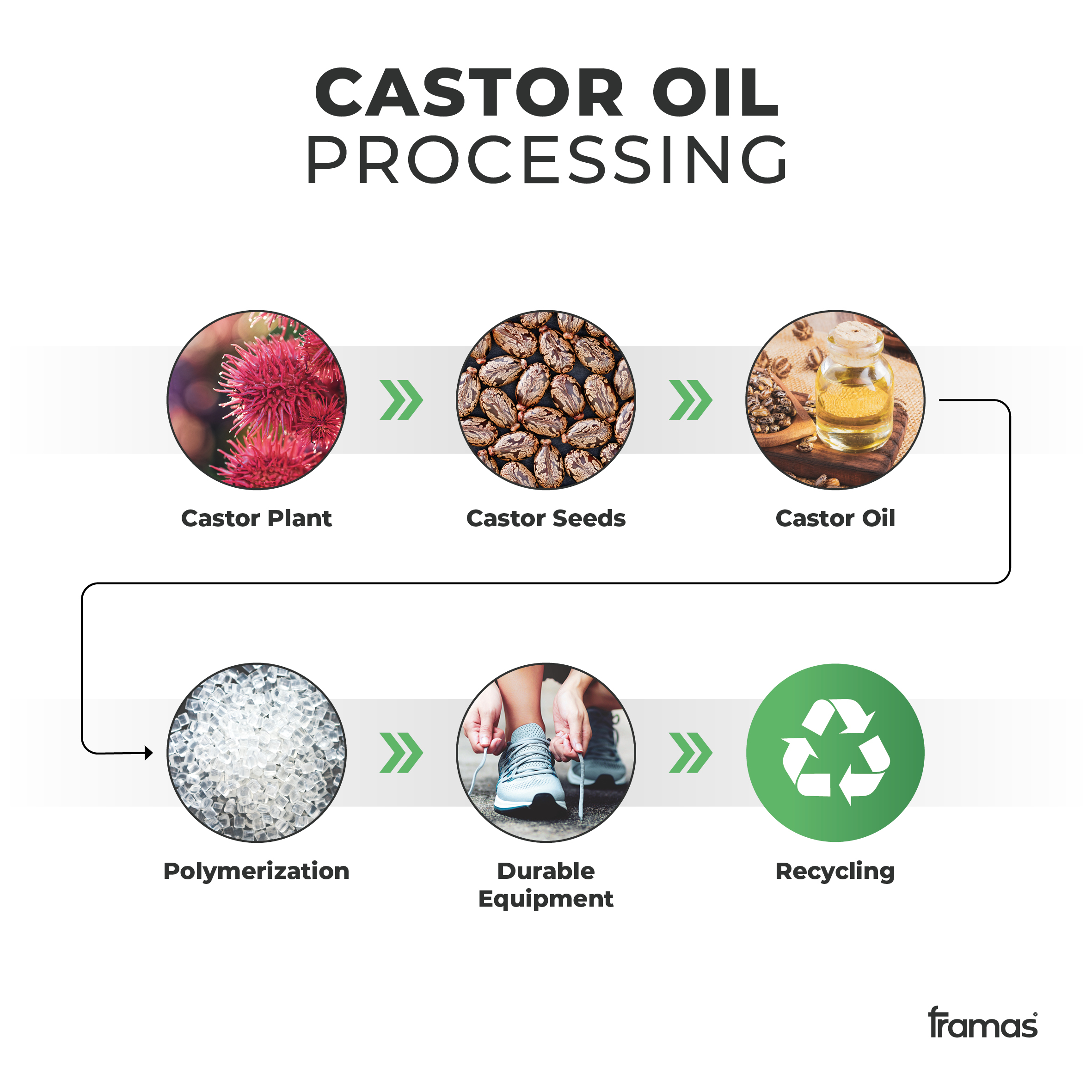

Once the seeds have been collected, the seed is removed from the hull by hand or with a machine. The seeds are then cleaned and heated because high temperatures allow for a higher percentage of oil extraction. Castor oil can be extracted 3 ways. Through mechanical pressing, solvent extraction, or a combination of both. Mechanical pressing uses a machine, hydraulic or screw press, to crush the seed to get crude oil out. Solvent extraction uses a chemical method to extract crude oil out. This is sometimes used additionally to the mechanical pressing to produce certain lower value oil grades.

After harvesting the seeds, they are heated then crushed through the mechanical pressing. The oil is then filtered and combined with new seeds for repeat extraction. On average, a castor seed contains 45% oil by weight, meaning that harvesting 1000kg of castor seeds will yield 450kg of oil. Depending on the seeds varieties, climatic conditions and agricultural practices some seeds contain more oil than others. Once all the seeds have been pressed, the residual bulk, also called castor cake or meal, is removed from the pressing equipment. Castor cakes usually retain 10% of oil so it is beneficial to also recover the oil through solvent extraction. The oil is once more filtered and then sent to the refinery for processing. The remaining seed cake is then mainly used as an organic fertilizer.

Why is the use of castor oil beneficial for the climate?

Global warming has become an increasingly important subject. Burning fossil fuels to produce energy contributes to the increasing level of CO2 in the atmosphere. The consumption and emission of fuel is set to rise so finding a sustainable material source is of high importance. The castor plant is a bio-based source which can take on multiple materials such as textile and plastic thanks to its high oil content. In the footwear industry this is beneficial for the environment as it elongates the CO2 usage due to the strong nature of polymers. They can endure multiple lifecycles, so the CO2 used to produce a castor-based material is being re-utilized when the material is being used multiple times.

Castor oil price is typically double compared to other vegetable oils such as palm and soybean oil, that are produced in much higher quantities.

The castor plant is also seen as a favorite non-food crop for the future as it does not compete with the agriculture of food. So even if demand grows, there is no fear of decreasing food plantation by increasing castor plant plantation. If there would be a competition for land between food crops and the castor plant, the castor plant would be moved into marginal soils due to its capability to adapt to different environments.

Not only is the sustainability of the material important but also how the material is produced. A number of initiatives to support the farmers and to improve the three main aspects of the activity: social (such as working conditions, compensation etc), economic (such as good agricultural practices to improve yield and reduce costs) and environmental (optimal use of water, fertilizers etc).

(If you would like to learn more about other green materials, then make sure to check out our blog post.)

In which industries is castor oil used?

Castor oil and the shoe industry

To avoid use fossil fuels with the consequent overwhelming resource depletion situation in which we live today, the shoe industry, amongst many other industries, is utilizing more and more renewable resources such as castor oil. Castor oil is a good alternative to petroleum-based chemicals as the oil can be converted into several materials such as synthetic textiles and hard plastic.

Bio-based polymer have comparable and sometimes better properties than petroleum-based polymers and have a lower carbon footprint when compared to similar materials. The oil goes through a polymerization process which turns the oil into pellet forms suitable for typical application of thermoplastic polymer such as injection molding and industrial filaments. The bio-based polymer made from castor oil can therefore be used in multiple parts of a shoe which can help reduce waste and encourages a sustainable development in the shoe industry.

Arkema Rilsan® PA 11 and Pebax® Rnew® TPEs

The French material supplier Arkema utilizes castor oil as renewable feedstock to produce their two flagship material families Rilsan® PA 11 and Pebax® Rnew® thermoplastic elastomers (TPE-A). These are part of their range of Advanced-Bio-Circular (ABC) materials, providing a solution for a circular economy. Their products are used in innovating industries as their Rilsan® PA 11 and Pebax® Rnew® materials are proven to be high-quality materials in the most demanding applications. Their focus is on recycling and producing high performance products with a long lifetime.

A typical athletic shoe has an outsole made from rubber or thermo plastic whilst the upper, midsole, insole and inside lining are made from synthetic material. Pebax® can be used in midsole components such as shank systems, propulsion plates and heel counters whilst also providing a high energy return. Pebax® can also be used to produce foam midsoles. Outsoles, such as cleated footwear, made from Pebax® are lightweight but still rigid, flexible and have a high energy return. Inside lining can be made from Rilsan® PA 11 which can be turned into a breathable and light material. (To learn more about polymers, check out our blog post about injection molding)

Rilsan® PA 11 is a polyamide, a synthetic polymer, with a specific crystallinity profile and is 100% bio sourced. It uses castor oil as a base which is a 100% renewable origin.

Benefits of Rilsan® PA11:

- Flexible

- Dimensional stability

- Easy to process.

- Accommodates countless additives and filling agents.

- Wide range of working temperatures

- Impact, fatigue, and abrasion resistance

Parts therefore have a longer lifetime which reduces waste. The material is used to produce yarns for the upper or laces and other synthetic material parts in shoes such as plates or outsoles.

Pebax® (PEBA TPE family) are made up of rigid polyamide blocks and soft polyether blocks, giving this material a large flexibility spectrum. They find application as high rebound foams for midsole, propulsion plates or shanks and outsole plates in cleated footwear. A cleated footwear made from Pebax® can bend 90 degrees without breaking and can endure more than 50,000 washing cycle.

Benefits of Pebax®:

- Large flexibility spectrum

- Low weight, elasticity, comfort, toughness, and flexibility

- Advantages to TPU: 20% lighter, more reactive and responsive

Midsole foams, midsole inserts and outsoles are all fabricated with Pebax® materials.

What changes are needed to make the castor plant more available and user friendly?

Several global programs are also trying to create a castor plant with a high seed yield, increased oil content in the seed and adapted to mechanical harvest. For the latter, the plant should be short (ideally half the size of current plants), have a steady growing state and produce a minimum number of leaves. This would help minimize the losses as well as not cause clogging in the machines. Until the present moment, there has been no success to cultivate a seed which comprises the elements from above.

However, an increase of the yield of the current varieties of castor plants can be achieved using better agricultural practices, with optimized irrigation or spacing between plants for example.

Summary

Benefits

- High availability

- Grows in a variety of tropical climates

- Adapts to drought

- Non-food competition

- Highly profitable for the farmers

- Dried beans have good shelf life, meaning it can be stored for a longer amount of time without turning bad

- Castor oil-based polymers are biobased, non-biodegradable, non-toxic, and offer a better sustainability profile

- Prevent the depletion of fossil resources

Challenges

- Extension to other regions to follow the growth will require time and efforts

- Development of mechanical harvesting requires optimization in the machines

*This article is created in cooperation with experts from Arkema to provide you a deeper inside into this topic. It is not sponsored or paid in any way.

If you liked this article, make sure to follow our Social Media channels and leave your feedback. You can contact us anytime via LinkedIn, Instagram & Facebook. We are happy to receive any feedback and tell us what other topics are of interest to you. We will try to address them in the near future.

Thanks for checking out our blog!

Neueste Kommentare