How safety footwear enhances protection in the workplace

23.05.2023 · Jennifer Merkel & Ariane Brinkmann / Editor Karolina HoffmannSafety shoes have an important place in the workplace. They protect the feet against injuries and help to reduce the number and severity of accidents. They can protect against punctures, cuts, burns and impact whilst also offering the individual a better grip when walking on a specific surface.

They have to follow basic requirements and offer additional protection for their area of application. For example, when working on a boat, the surface can be very slippery, so it is important to have a shoe which allows the individual to move around without the fear of slipping. For someone working with electricity, the shoe can prevent electrical hazard. Workers in the forest can also encounter a slippery surface from moss but there is also the possibility of getting cut when working with chainsaws. A safety shoe made from cut resistant materials can help prevent getting cut.

Navigation

What are safety shoes?

Process of making a safety shoe

Fundamental requirements of safety footwear

Process of making a safety shoe

· Safety category S1

· Safety category S2

· Safety category S3

· Safety category S4

· Safety category S5

· Safety category S6 + S7

Summary

What are safety shoes?

Professional footwear can be distinguished into two categories. The first category is work footwear, meaning that the shoe is within the anti-slip and water repellent criteria, but the toecap and insole are not impact resistant.

The second category is called safety footwear, which is a shoe that must meet the EN ISO 20345 norms. This requires the shoe to have a minimum impact resistance of 200 Joules at the front-end part of the shoe and to be slip resistant on smooth and greasy floors in industrial environments. Different specific protections are then added onto the shoe to fulfill the protection criteria the shoe is meant for.

Process of making a safety shoe

A safety shoe begins with a conceptual design, which is then tested until it satisfies the requirements. The material for the upper part of the shoe is chosen depending on the functionality the shoe is supposed to have. The sole and the toe cap are also based on the function of the shoe.

Once all the materials have been chosen, the parts for the upper are cut out, assembled and then placed on the shoe last. Once on the shoe last, the toe cap is added underneath the main fabric and the shoe gets pressed together by a machine to help the shoe take form and make the toe cap fit well around the front part. Thermoplastic is then injected into the molds for the sole to then produce the outsole. Once the sole is connected to the upper part of the shoe, a safety shoe has been made. (You are interested in learning more about the specific requirements, when making a shoe last? Then click here.)

Fundamental requirements of safety footwear

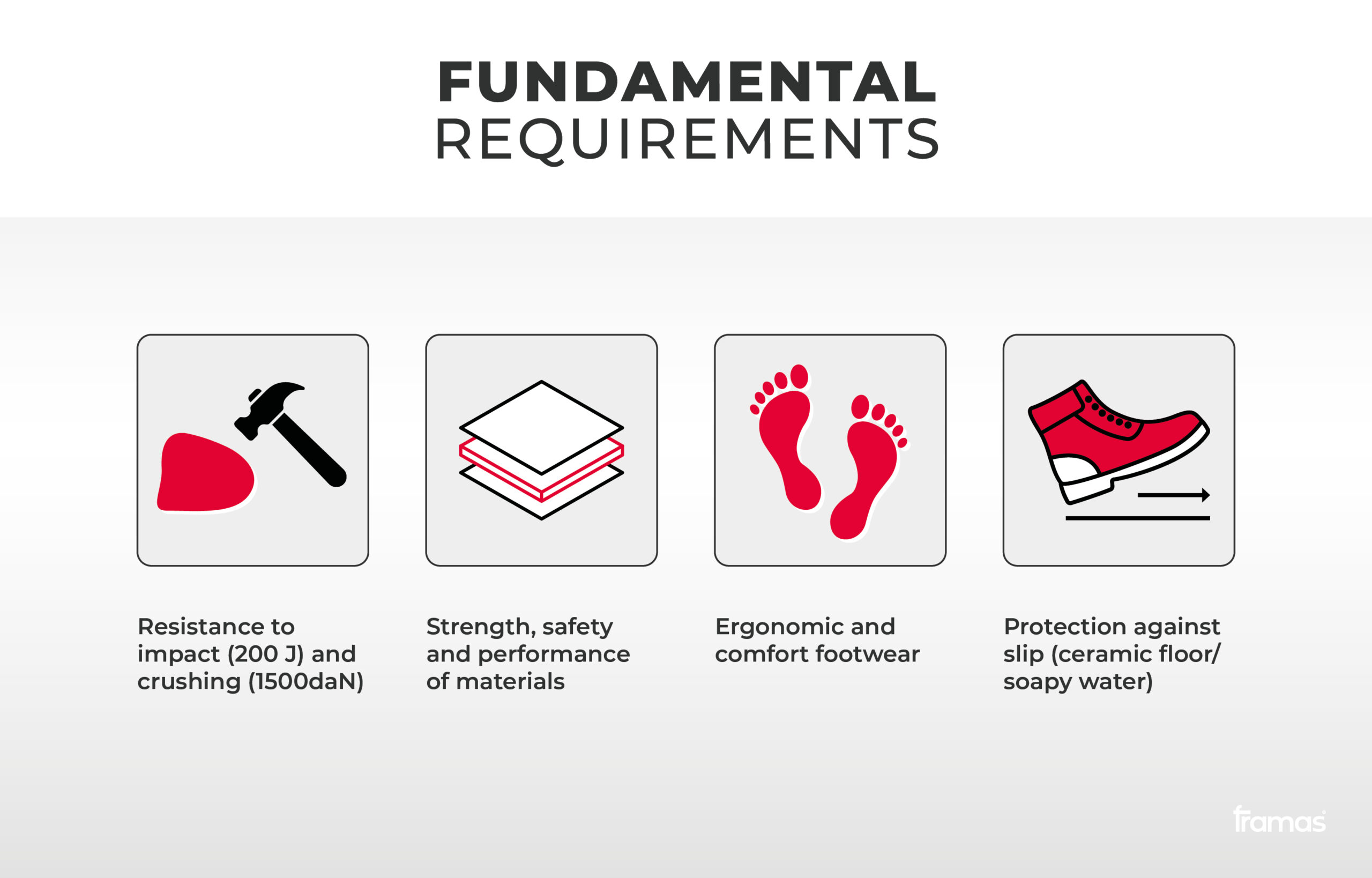

The basic requirements of a safety shoe can be found in the standard basic (SB) degree of protection. This includes a sole which is anti-slip, anti-abrasion oil resistant and anti-static. The non-slip properties must be true on ceramic tiles with cleaning agents (SRA), on steel floor with glycerin (SRB) and on the two types of floors combined (SRC).

Furthermore, the materials used to build the shoe have to be water resistant, breathable, hard wearing, and strong. The shoe needs to be comfortable, and the toe cap needs to be impact and crushing resistant. The toe cap can be made from steel, plastic or aluminum and needs to have an impact resistance of 200 Joules. This means the toe cap should withstand a weight of 20kg from a fall height of 1 meter. A SB safety shoe provides the minimal amount of protection but provides more protection than a normal work shoe.

Process of making a safety shoe

All safety shoes must meet these basic requirements but there are additional requirements depending on the shoe’s area of application. The additional safety features on the safety shoes are depicted on the label via a symbol and can be divided into 3 categories: complete footwear, instep and the sole.

Complete footwear includes the following:

1. Puncture resistant (P) insoles, which are resistant to a puncture force of 1,100N.

2. Conductive footwear (C) which, by evaporating electrostatic charges, is electrical resistant from 0 to 100 kilohms.

3. Antistatic footwear (A) dissipates electrostatic charges between 100 and 1000 kilohms.

4. Heat resistant soles (HI) allows an insulation against heat up to 150 degrees.

5. Cold resistance soles (CI) allow an insulation against cold up to -17 degrees.

6. The heel area must absorb a minimum of 20 Joules energy (E).

7. Metatarsal protection (M) provides additional safety for any of the bones in the foot.

8. Ankle protection (AN) adds additional ankle protection.

9. Cut resistant (CR) features are zones of the shoe which are resistant to getting cut.

10. Waterproofing (WR) means that the entire shoe must be waterproof.

Instep requirements are specifically directed towards the middle part of the foot. There is only one additional requirement, which is that the upper part of the shoe is resistant to water entering and the absorption of water (WRU).

The sole has two requirements. It can be resistant to contact with heat (HRO) for temperatures up to 300 degrees and can also additionally be resistant to hydrocarbons (FO) which are highly combustible chemicals.

The different degree of protection provided by these safety shoes are indicated by the S, meaning standard, and a number. The higher the number, the more extensive the protection which goes from S1 up to S7. Safety shoes can be divided into two categories depending on the material the footwear is made from. The first category has a leather or other synthetic material upper (S1-S3, S6, S7) whilst the second category has an upper made from rubber, PVC or PU (S4 and S5).

Do you want to learn more about different plastics used in injection molding. Then check out our blog post here.

1. Safety Category S1

The degree of protection S1 meets all the basic requirements (SB) and additionally has closed, shock and energy absorbing heel (E). In addition the sole must be hydro-carbon resistant (FO) and anti-static.

S1 is good for interior activities in dry places where the importance of the shoe is to have basic protection. Contact with water tends to be non-existent. This applies to jobs such as electricians, mechanics, and craftsmen.

2. Safety Category S2

S2 meets the basic requirements and those of category S1, whilst also providing resistance to water and liquid absorption in the upper part of the shoe.

Safety shoes which follow the S2 requirements are useful in work areas with a high level of humidity where basic protection is still sufficient. This can be useful for someone who works in the food industry in the storage and the transportation. An airport worker would need an S2 safety shoe but with a plastic toe cap which is lighter than metal and allow to have a metal-free shoe which is beneficial in airports.

3. Safety Category S3

S3 meets the standards of category S2 and provides a lugged sole and a resistance to sole puncture. A lugged sole is a thicker outer sole with deep indentations.

Activities which happen in hostile work situations would benefit from S3 safety shoes. The shoe allows the person to have basic protection on their feet with the upper part of the shoe being water resistant and to have a sole which is thick and sturdy. Jobs in mining, agriculture, factories, or construction often use shoes with the S3 standard. A forestry worker needs protection against sharp working tools and slippery surfaces. This calls for a safety shoe with S3 requirements and cut resistant features. Production or factory workers also wear S3 safety shoes as they need to protect their feet from materials falling and be able to move around comfortably.

4. Safety Category S4

5. Safety Category S5

6. Safety Category S6 + S7

S6 has the same specification as S2 but the whole shoe is water resistant.

S7 refers to the S3 category and the whole shoe is water resistant. A fireman encounters multiple elements such as fire and water. Therefore, the entire shoe must be heat and water resistant. It must ensure that the high heat will not enter the shoe. The sole must be thick enough to stabilize the foot of the fireman when walking on challenging terrain. Shoes with a S7 certificate would come into consideration as they offer the most safety and the whole shoe is water resistant.

Summary

In summary, a safety shoe is used in multiple applications to help protect the feet from any injuries and to facilitate movement in the workplace. There are basic requirements which all safety shoes must follow but they differ in their degree of protection. S3 shoes have the most extensive protection in the market at the moment.

If you liked this article, make sure to follow our Social Media channels. You can contact us anytime via LinkedIn, Instagram & Facebook. We are happy to receive any feedback and tell us what other topics are of interest to you. We will try to address them in the near future.

Thanks for checking out our blog!