Green materials for the footwear industry

21.03.2023 · Expert Sebastian Wendling & Felicitas Huong Friedrich / Editor Jakob Hellgren & Luisa-Maria MrcelaSustainability has become a very important topic in all areas of our daily life. Especially the fashion industry has to rethink its production patterns because it belongs to the industries, which harm our environment the most and accounts up to 10% of the global greenhouse gas emissions.

Therefore the industry is looking for new solutions to become more sustainable. As you might have read in our previous blog post, creating a sustainability report is a starting point for every company to see in which areas it has to improve. A report also acts as a transparency index for the companys customers and partners.

But what is really changing the industry are new products which are less harmful for the environment. Those products need to have an increased lifetime and must be recyclable. One way to do this is by using more so called green materials.

In this blog post we want to give you an overview of green materials, what they are and how to decide which one to use for your product.

Navigation

Reduction of Carbon Footprint

What is a green material?

How to pick the right green material

Green materials in the footwear industry

· Cellulose

· Lignin

· Starch

· Chitin

· Hemicellulose

· Suberin

· Lipide

Sneak Peek: Cork

Reduction of Carbon Footprint

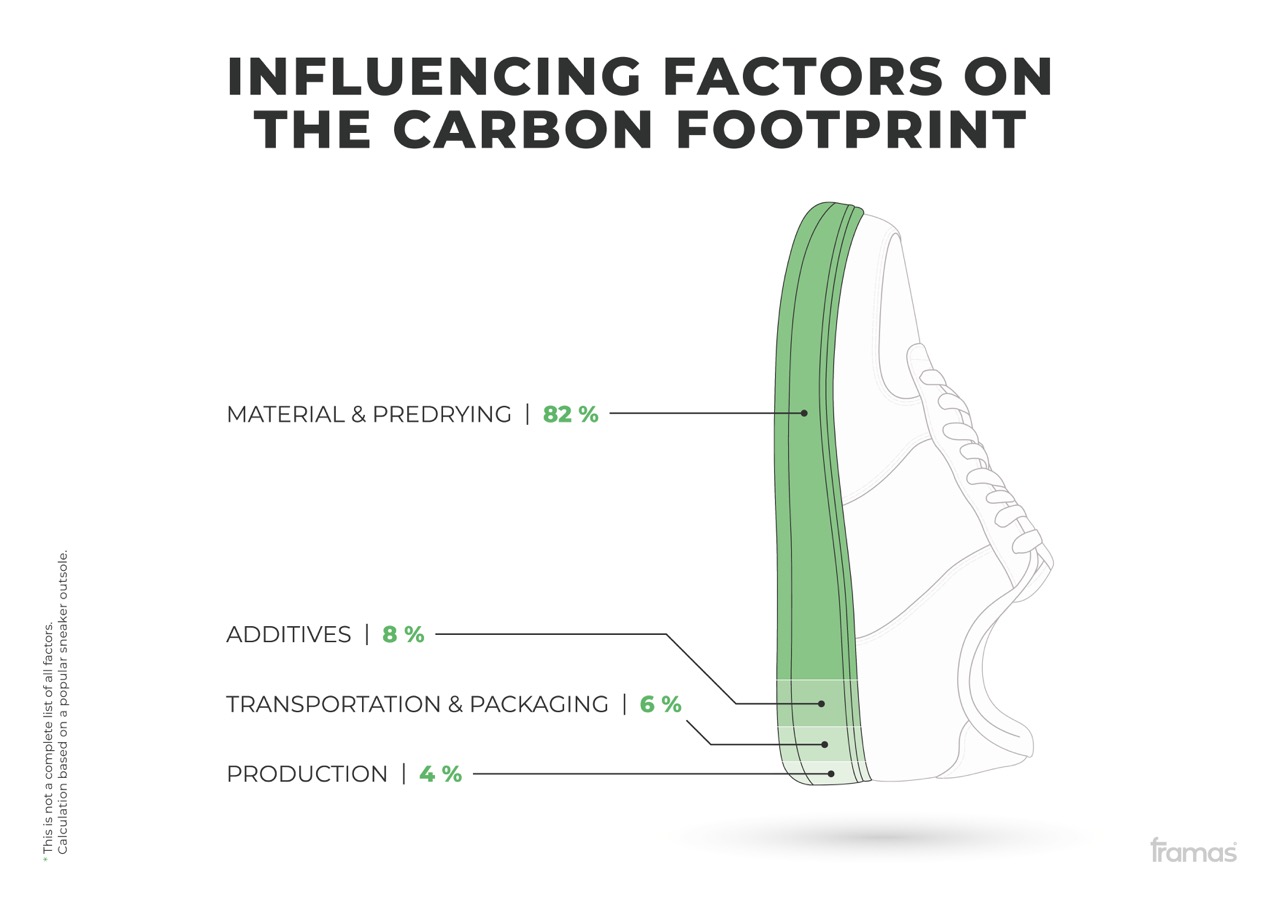

First of all, we need to talk about the Carbon footprint. A carbon footprint gives an indicator of how much CO2 a product is producing during its lifetime. There are many drivers of CO2 and other emissions in a footwear manufacturing process. While production has 4% impact on CO2 emissions, transport has 6%, materials has 82%. In this blog post we will focus on the impact of materials and how to lower it by using green materials.

(This is not a complete list of all factors. Calculation based on a popular sneaker outsole.)

What is a green material?

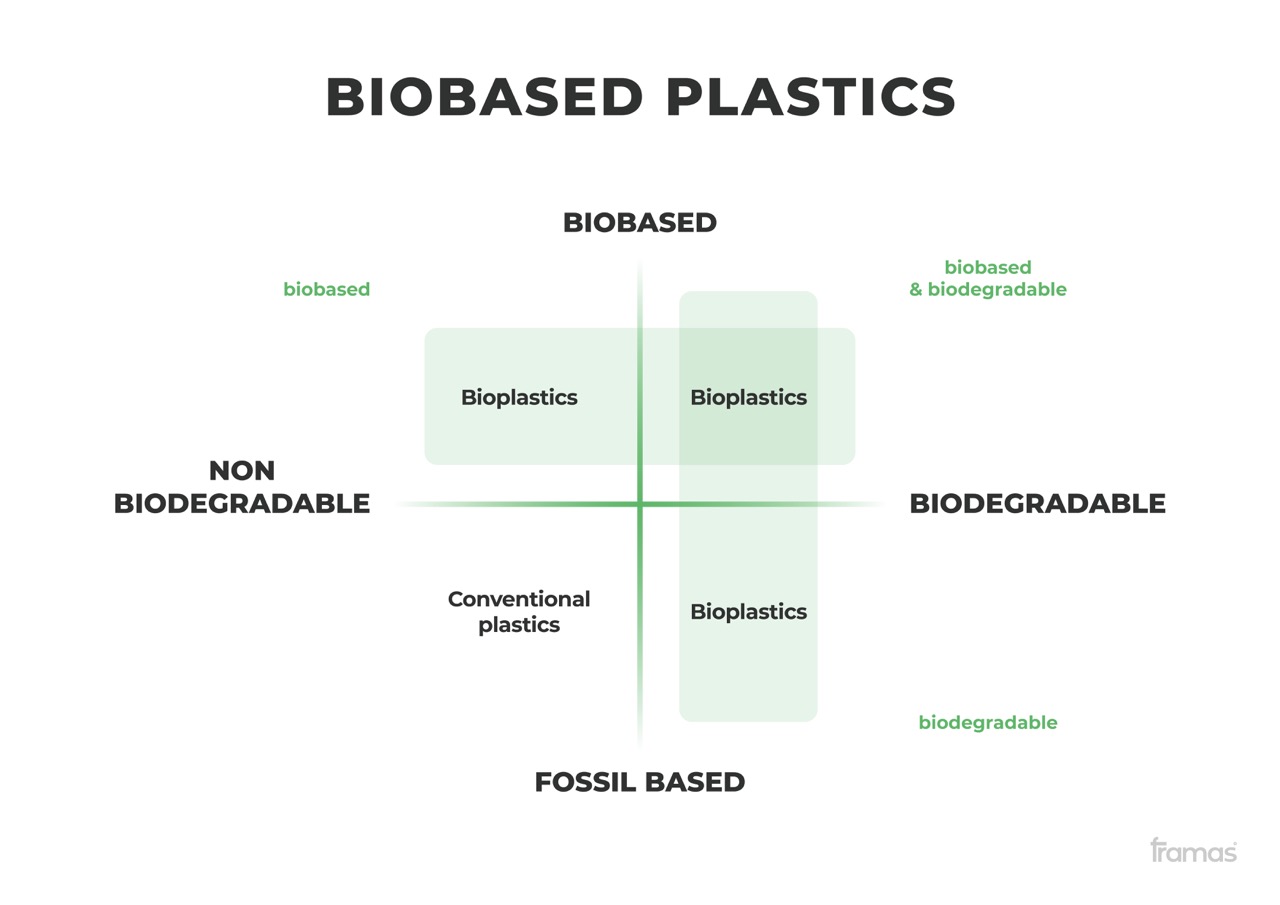

To understand what green material in the footwear sector is, it is helpful to demarcate it by three criteria: Is the material fossil or organic, is the material biodegradable or not, and can it be recycled or not? The graphic shows 4 categories of footwear materials and assigns materials respectively into their categories.

How to pick the right green material

A guideline structured by common footwear application requirements

The selection of the right material is a trade-off. A footwear developer must meet design intent, performance factors, sustainability aspects, manufacturability, costing/profitability and commercialization factors to satisfy the entire footwear creation team. With the drift towards plant-based materials, the number of criteria to fulfill are becoming even more. While fossil-based materials are manufactured by established suppliers with consistent processes and a long history of enhancement, the green material market is still diverse and due to a high variety of polymer sources, much more complex to overlook. Time for a guideline to ease the job of footwear creation teams.

In the following we break the factors down for you, which have to be kept in mind by choosing the fitting material:

1. Design Intent

It is the objective of every footwear developer to meet the intentions of the footwear designer. The number of uncertainties in a footwear development process make it challenging to meet it by 100%, but it is key for a smooth collaboration. When it comes to the material selection, pointing out the requirements helps avoiding deviations from design.

Some components material must be transparent to highlight component layers below. To ensure that the material is fulfilling the promised design effect, a translucency test is recommended to conduct.

Design and manufacturing places can differ a lot. It is not uncommon that the designer builds prototypes at dry-air places in Europe or the US first, but the mass production takes place in Southeast Asia – countries known for a high humidity. Materials can react to constant wet environments by changing their color or properties. A test called yellow index can mitigate the risk of design deviation during the manufacturing process.

When picking a material, it should also be determined in advance if the material needs to be colored or not. Some green materials come already colored by nature and must be taken how they are or must be colored by e.g., color coating. Therefore, the surface of materials must be suitable for decoration. Materials with thermoplastic properties can be prepared with color pigments and can therefore fulfill all designer’s imagination.

Also the shrinkage of the material, compared to its intended size, must be kept in mind. A shrinkage test is strongly recommended to conduct in advance.

Depending on the design, the dimensional stability of the material could also be a critical factor. To ensure the materials functionality, the material should be exposed to the related environment in its original target dimensions.

2. Performance

Most sport brands core values are based on performance. Therefore, footwear creation teams can only substitute fossil materials with plant-based materials if the performance does not decrease. There are a bunch of parameters giving a clue how the material will perform on the shoe later on.

If you need a lightweight shoe, you should make sure that the specific density is as low as possible. If a tough material is your choice, which has to fulfill safety standards, there are three important parameters all provided by one single test (tensile test) that must be looked at.

To count as a stress resistant (high tear strength) the material should not break under high intensity. If the material shows a good breaking elongation, it can be stretched without deforming. Lastly, the Young’s E-Modulus tells you if the material can be strained intensively and then moving back fully to its initial shape.

If the respective shoe needs to stand extreme conditions (e.g. cold), you should conduct a fatigue bending test under very low temperature (e.g., -10 degrees Celsius).

If your shoe must stand moist or humid weather conditions without absorbing water, conduct a moisture absorption test. When the shoe should be used for more than 1000 miles, your outsole material should display have very low values in an an abrasion resistance test. It is wise, to conduct the test with different undergrounds, especially if your customer are doing all-track activities.

The coefficient of friction testifies how good the traction of a material is. Depending on the shoes requirements it can be conducted on flat, lopsided, dry, wet, or even icy underground. The options of potential variating undergrounds are almost unlimited and should be selected wisely in advance during the material decision process.

Before choosing the material, you should also know where in the shoe it is supposed to perform. Covered and hidden in the shoe or visible? If visible, then it will likely be exposed to the sun and water. An UV-test will tell you how fast a material would lose pigmentation when exposed to the UV light. Another test indicates the speed of color change during the exposure to water. For both tests, a so-called grey scale is supporting you to find an acceptable range of sun and water resistance.

3. Sustainability

Only because a material is bio based, it does not automatically guarantee that a material is sustainable.

It is important to consider the materials impact over the entire lifetime. More than that, you should know the origin of the actual raw material, the entire manufacturing process to the ready-to-use footwear material, the manufacturing process from ready-to-use material to the footwear component and consider the lifetime of the actual material in the component.

Obviously, the longer a consumer can take advantage of a functioning shoe, the less frequent it needs to be replaced with a new product. Consequently, the biopolymer must be chosen by the criteria of material durability. To ensure this, the material needs to pass the abrasion test, should be resilient against stress in the tensile strength test and must be flexible without breaking in the breaking elongation test.

Another option to extend the materials lifetime would be recycling. Many biobased materials are biodegradable, but not all are recyclable. For instance, all fiber-based materials simply burn and turn black if recycled.

For some footwear applications it can be sufficient that a material, of which the footwear component is made, is not lasting much longer than the shoe itself. The ability and speed biodegradability tells you how long it takes until your plant-based material is decomposed to its organic molecules.

One of the most apparent sustainability indicator is the carbon footprint (kg carbon equivalent/ LCA). Due to missing information material suppliers are not yet able to calculate a carbon footprint equivalent for all materials. In case of not existing values, an emergency thumb rule can help: The less manufacturing steps from raw material to ready-to-use product, the lower the carbon footprint.

However, not all biobased materials have excellent thermal properties which makes them capable to run through a recycling loop multiple times without suffering in mechanical, optical, physical, and thermal quality. For instance, a multiple times recycled material can get a worse appearance showing yellow or black dots. Before confirming a new material, it is strongly advisable to repeat all tests required for the footwear application after every recycling cycle to determine the maximum number of loops without adding virgin material.

For fossil polymer products it is simple. They are fostered under the earth. Since plant-based polymers are harvested or fostered above the earth, it is always beneficial to know from what plant and where the main ingredient of your material is coming from. The knowledge of origin will support you to evaluate if the ingredients were harvested or fostered under socially acceptable circumstances or if agriculture could possibly expel people, animals, or sustainable economy. The knowledge of plant helps you to know if the plant could possibly threaten biodiversity or enforces dehydration of land.

You should also definitely check if during the extraction process the use of chemicals was necessary. This could lead to a negative biological impact.

4. Manufacturability

Delays during the manufacturing process are costly and can jeopardize critical deadlines. Knowing the manufacturing steps and methods, as well as the assembly process, in advance helps finding the right material which avoids material problems. The methods finally define the material requirements. Of course, it is practical to have a material which fulfills the requirement of all methods, e.g., injection molding, 3D printing, extrusion, powder coating. But sometimes specified materials, which can only be used for one method, might have more benefits than a “generalist”. Injection machines work within a certain temperature range. Therefore, while heating a material, it must melt before it is reaching a certain temperature, must resist high temperature, and must flow smoothly through the hot channels. Two tests, the melt flow rate (MFR) and the melting test can evaluate the material manufacturing suitability in advance.

Another aspect to consider for the manufacturability is, if the materials will be exposed to chemicals or glue during the manufacturing process. The chosen materials are recommended to be exposed to the respective chemicals and glues under laboratory conditions before manufacturing. Obviously, the less chemicals and glues are used the better.

5. Costing & Profitability

Also, for green materials costing remains a critical factor. Cost plans and forecasts for plant-based polymers are less predictable than for fossil-based polymers.

Since sources (plants) of green materials can underly much seasonal shortages, the price can be more volatile. Moreover, the availability of certain plants is limited and due to increasing demand of green materials even more, which is driving the prices upwards. In addition, the diversification of the market is still much higher than for fossil-based materials. Green material suppliers are also getting reimbursed for their pioneer work in research and development of new plant-based polymer alternatives. Some extraction processes for plant-based polymers are complex, which has also an effect on the price. When it comes to the selection of plant-based materials, footwear developers should consider especially the availability.

For the evaluation it is helpful to have as much origin knowledge as possible about the plant-based source. The cost premise should be to choose the material which has a high and safe availability.

If manufacturability, sustainability, design intention, or performance criteria require material with a lower availability a footwear developer should strive, if possible, to close exclusive long-term contracts with plant-based material suppliers. Another measure to decrease costs is to focus on the density of the material. The lower the specific density, the less cost per kg.

6. Commercialization

You need a good green material story. Nowadays, if you pick a plant-based material, you must be capable to tell a story about heritage, origin, or impact – creating a hype around this material to make the consumer willing to pay a bit more for the extra bio you added to the footwear. The more you know about the material, the better your bio-add-on story becomes. The next chapter is trying to enrich your green material knowledge.

Green materials in the footwear industry

When we talk about green materials which supposed to substitute fossil materials, we must keep in mind that those materials are often polymers recently made by nature. Sometimes you can just take the plant-based polymer how it is. Sometimes it requires one or several chemical or physical steps to process a material from the plant-based polymer to the final applicable footwear polymer.

Since the variety of polymer process has almost no limits, it is crucial to gain an understanding of the base elements for all green materials. The variety of plant-based polymer sources is high and the process to achieve the final applicable material for the footwear industry can be so complex that you can lose track about the real ingredient origin of the raw materials. It is definitely more beneficial to tell your team, stakeholders, and customers that your outsole is made of a certain plant that’s possibly growing next to their home than telling them just a random brand name, digits, or material number.

Time to sort things a bit and gain the overview in the world of bio polymers. Below, we provide you with a short portfolio of relevant bio polymer molecules, and respectively, in what plant source the bio polymer can be found a lot.

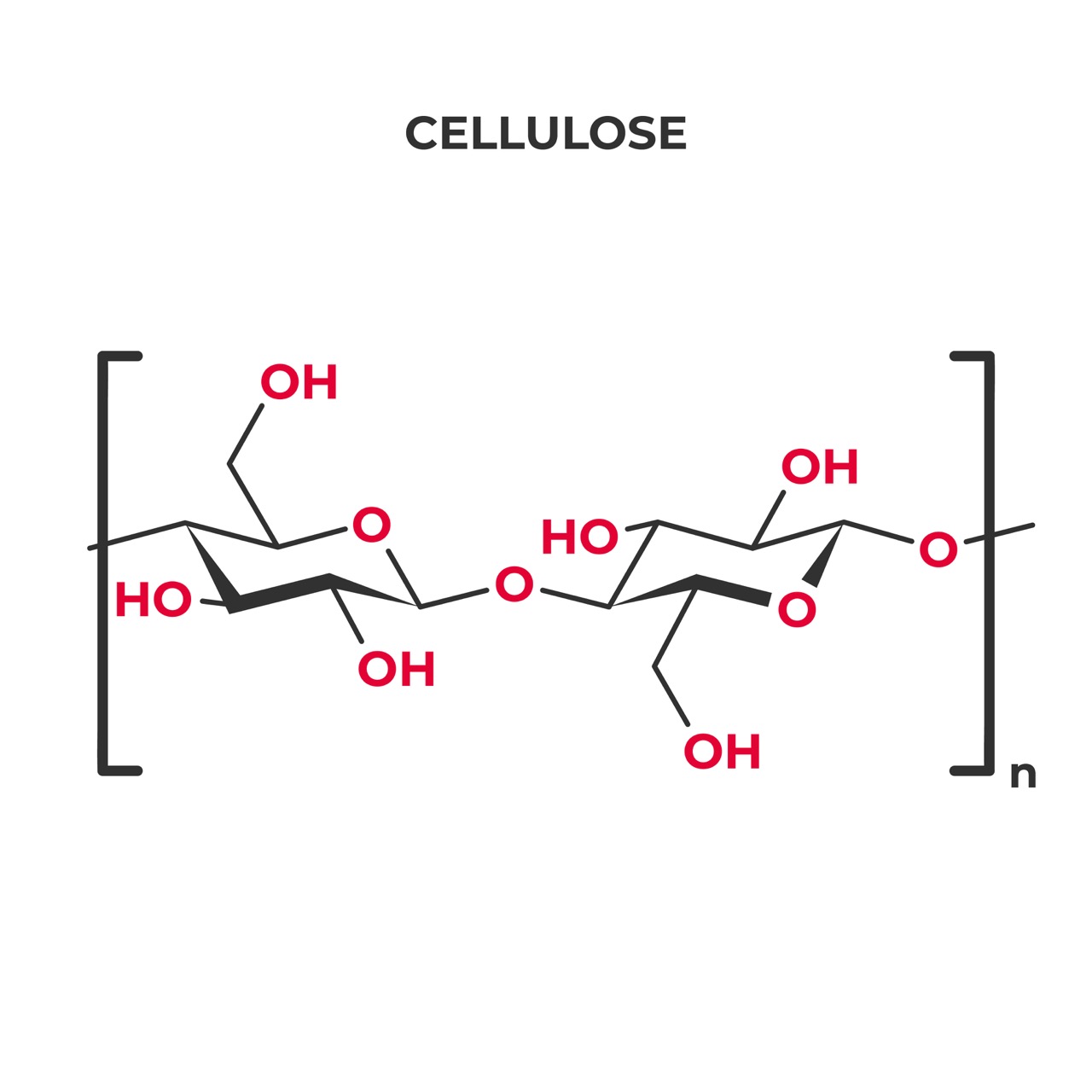

Cellulose

A green material of interest able to give footwear application a static structure is cellulose.

Cellulose is, as well as the biopolymer chitin, a polysaccharide (multiple sugar molecule). Cellulose is the most in nature occurring bio molecule, which makes it highly available for applications in the footwear industry. One reason its high availability is, that Cellulose is the main ingredient of most plant cell walls (up to 50% of cell mass).

In the clothing industry, both natural plant fibers consisting of cellulose and artificial cellulose fibers (CO) are used.

The paper industry is using cellulose mostly as raw material for high-quality paper.

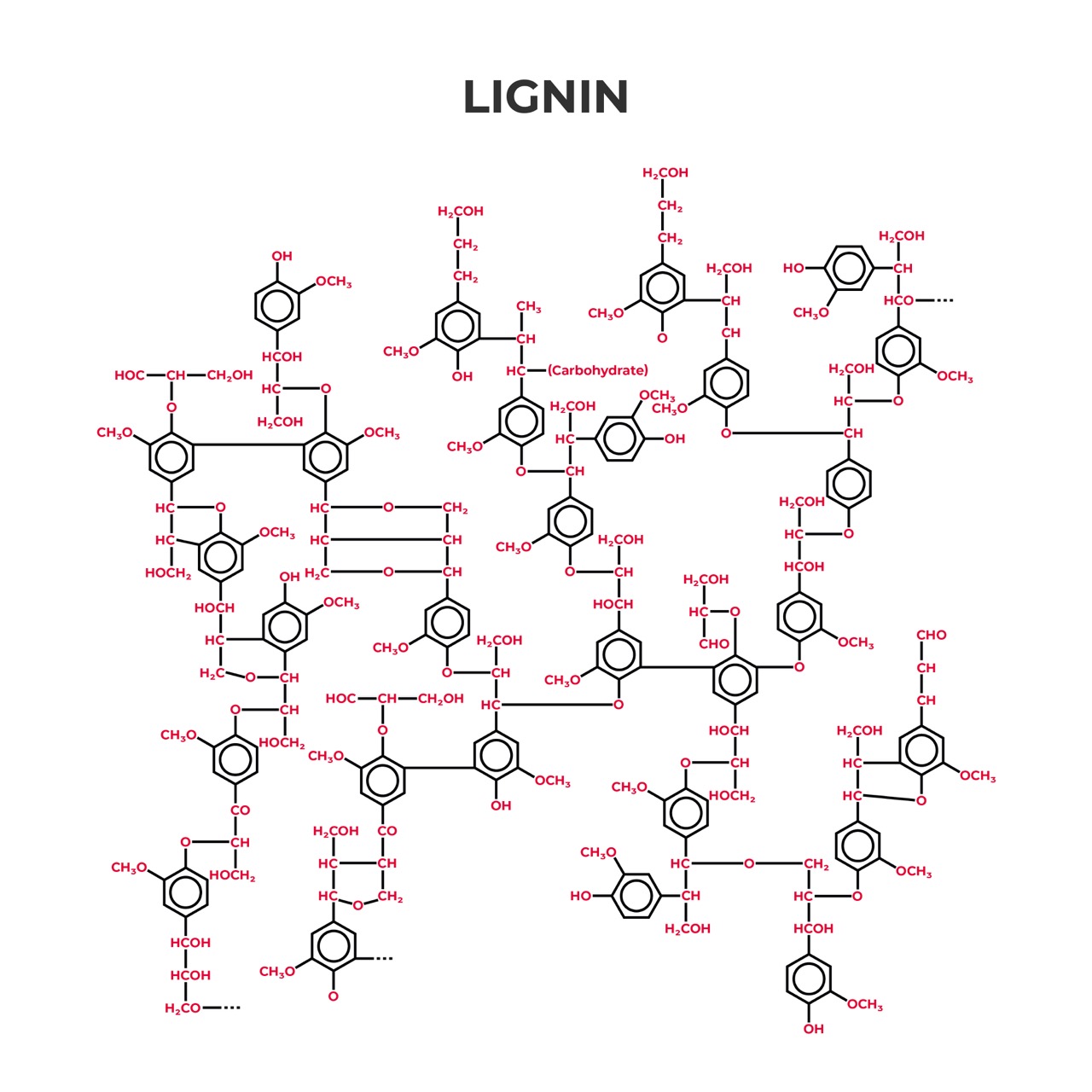

Lignin

Lignin is a stiff biopolymer which is stored in the plant cell wall. It depicts a highly complex polymer.

The polymer causes the lignification of cells (cells are becoming wooden), which makes land trees extremely stabile and resistant against pressure load from windy weather. For water trees it is providing the static lift because its low-density properties. The higher the pressure load of weather conditions on plants, the more the lignin proportion increases. The process is called lignin cellulose.

Tree plant cells can have a proportion of 20–30% of lignin, most plants have only a lignin proportion of less than 1%. The annual lignin production of trees is estimated to be 20 billion tons.

Mixed with cellulose of hemp and flax, Lignin can be applied for Injection molding and other plastic processing methods. With some chemical manipulation, lignin can even be processed to Polyurethan.

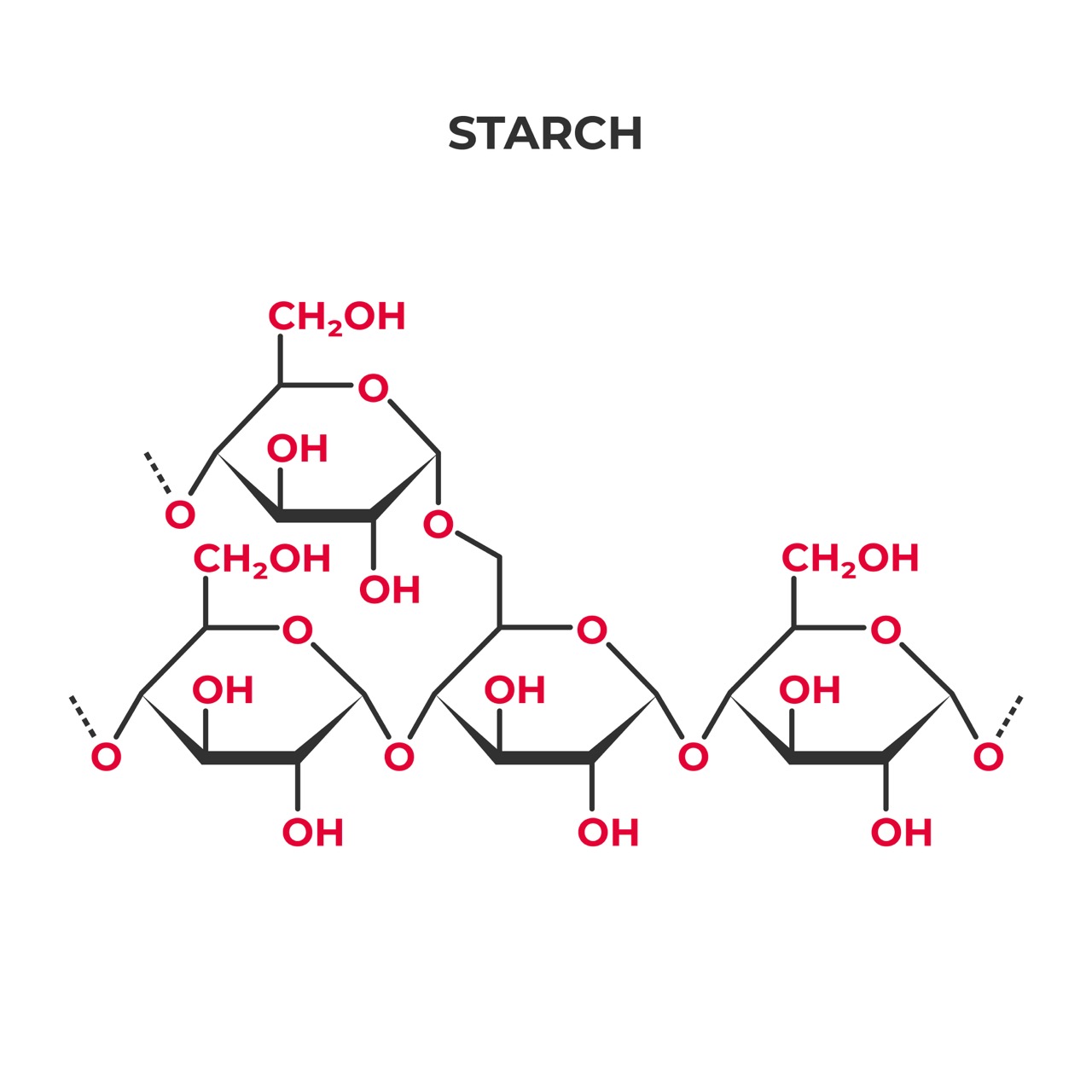

Starch

Starch is a polysaccharide which consists of glucose units. Therefore, it belongs to the carbonates. The substance is one of the most important reserve substances in plant cells.

Starch can for example be processed to a thermoplastic starch (TPS), which is one of the most important biopolymers on the market. Since TPS has strong water absorbing properties, it is often blended with other biodegradable, water repellent, polymers.

Another bio-based polymer which is using starch as a base polymer, is polylactide (PLA). By fermenting starch with the help of various bacteria lactide is produced, which is then being processed to PLA. PLA is a polymer and counts as a polyester. It is biological degradable. Moreover, thermoplastic properties (melting) make PLA in general suitable for plastic injection molding and extrusion.

However the low temperature resistance of PLA could be a problem for footwear application with high heat requirements. The material becomes weak between 50-60 Celsius degrees. Therefore, it is mostly used in combination with other materials, as a blend. By adding bio fibers, the temperature resistance can be increased up to 100 Celsius degrees.

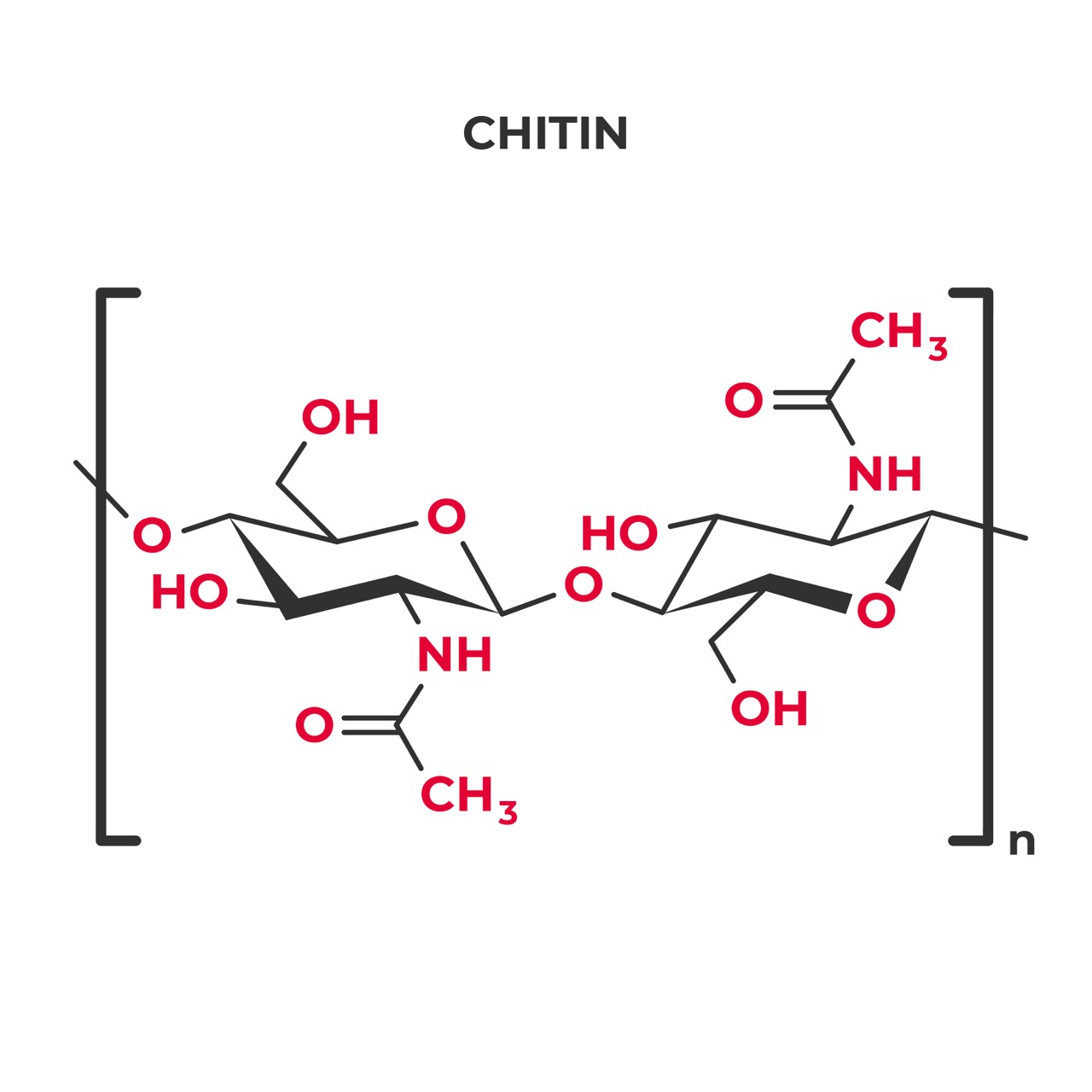

Chitin

Chitin (English: shield) is next to cellulose the most occurring polysaccharide. Chitin provides structure to cells. Chitin is the base material to derive chitosan.

Chitin can be found in the cells of mushrooms, mollusks (e.g., snails), as well as articulated animals (annelids, crabs, spiders, and insects). In mushrooms chitin is the main ingredient of the cell wall, whereas chitin is not occurring in all mushrooms.

Even though chitin and chitosan have excellent technical properties as a biopolymer, the practical application range is compared to other polymers still quite low. Although in the footwear industry, in particular chitosan could already be used as the base material for midsole or membranes, e.g., upper meshes.

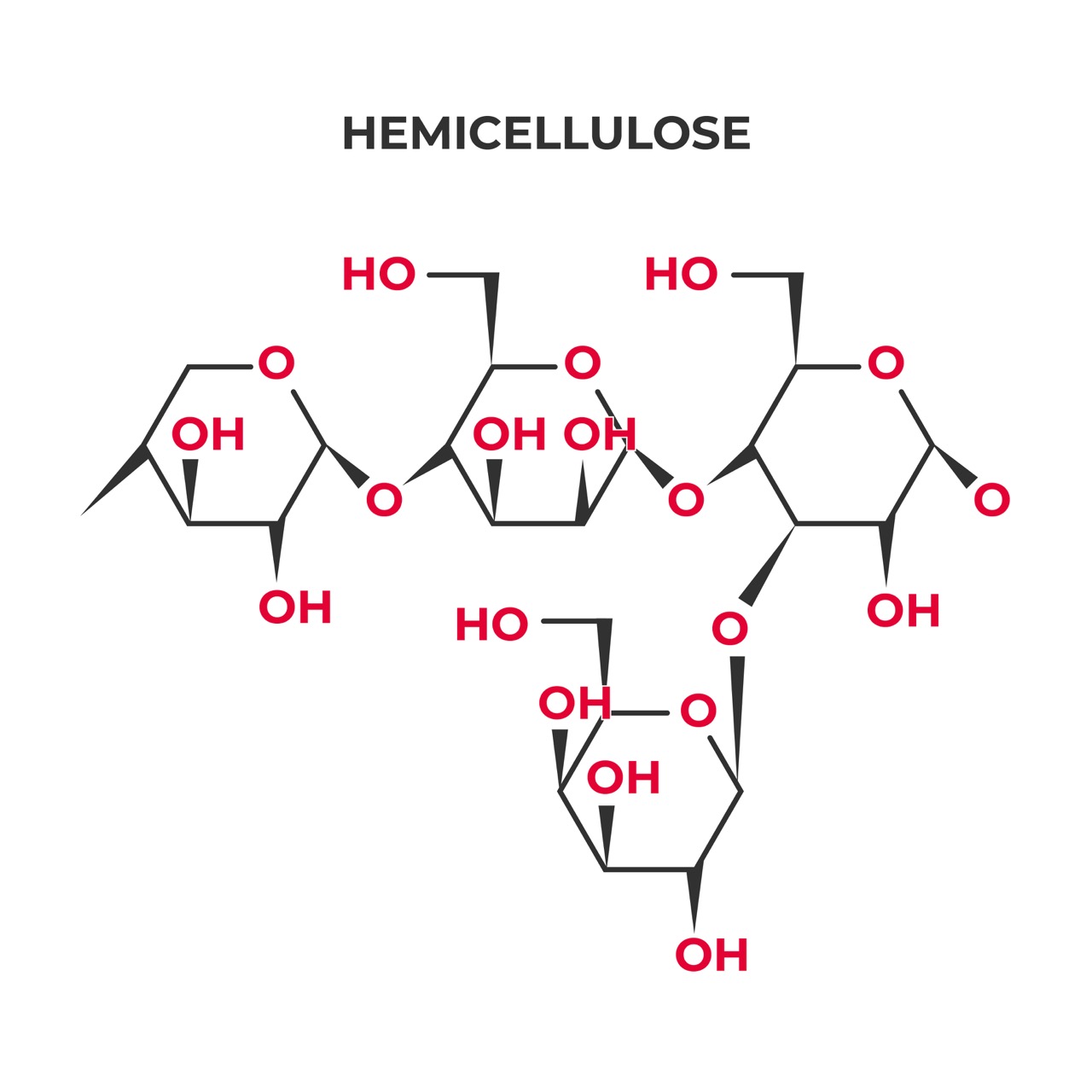

Hemicellulose

Hemicellulose is a collective noun for several polysaccharide types in the biomass of a plant cell. One of the most occurring hemicellulose types is pentose. It serves as a green base molecule for furfuran which can be the base material from polyamide (Nylon).

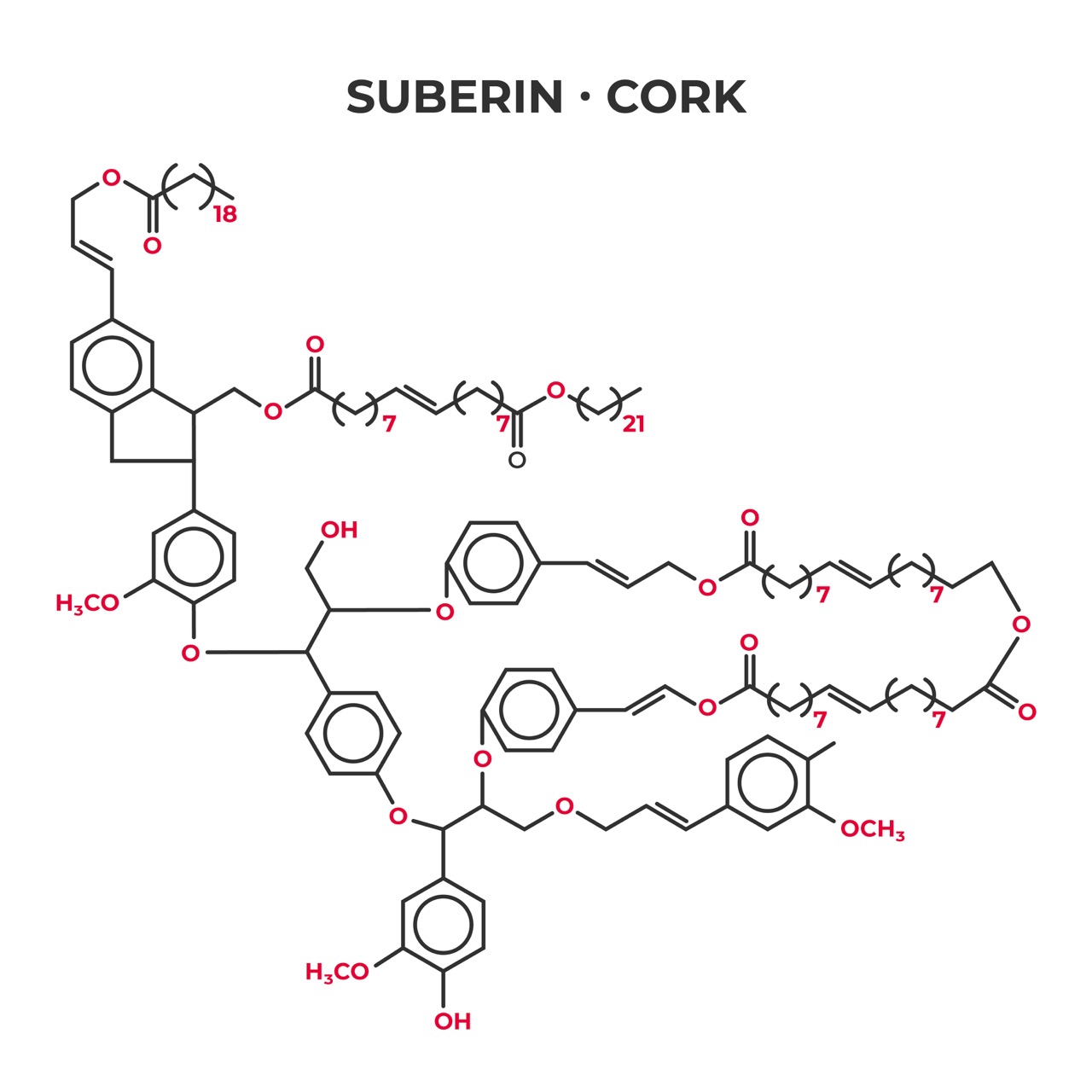

Suberin

Suberin also called “cork substance” is a high-molecular polymer occurring in the bark cells of the cork oak as well as in roots of trees. As a hydrophobic layer on cell wall, suberin makes the cork cells impermeable to water. It is one of the most durable of all known organic substances.

Suberin or its raw material cork has been used in famous footwear applications over decades e.g., a sandal midsole.

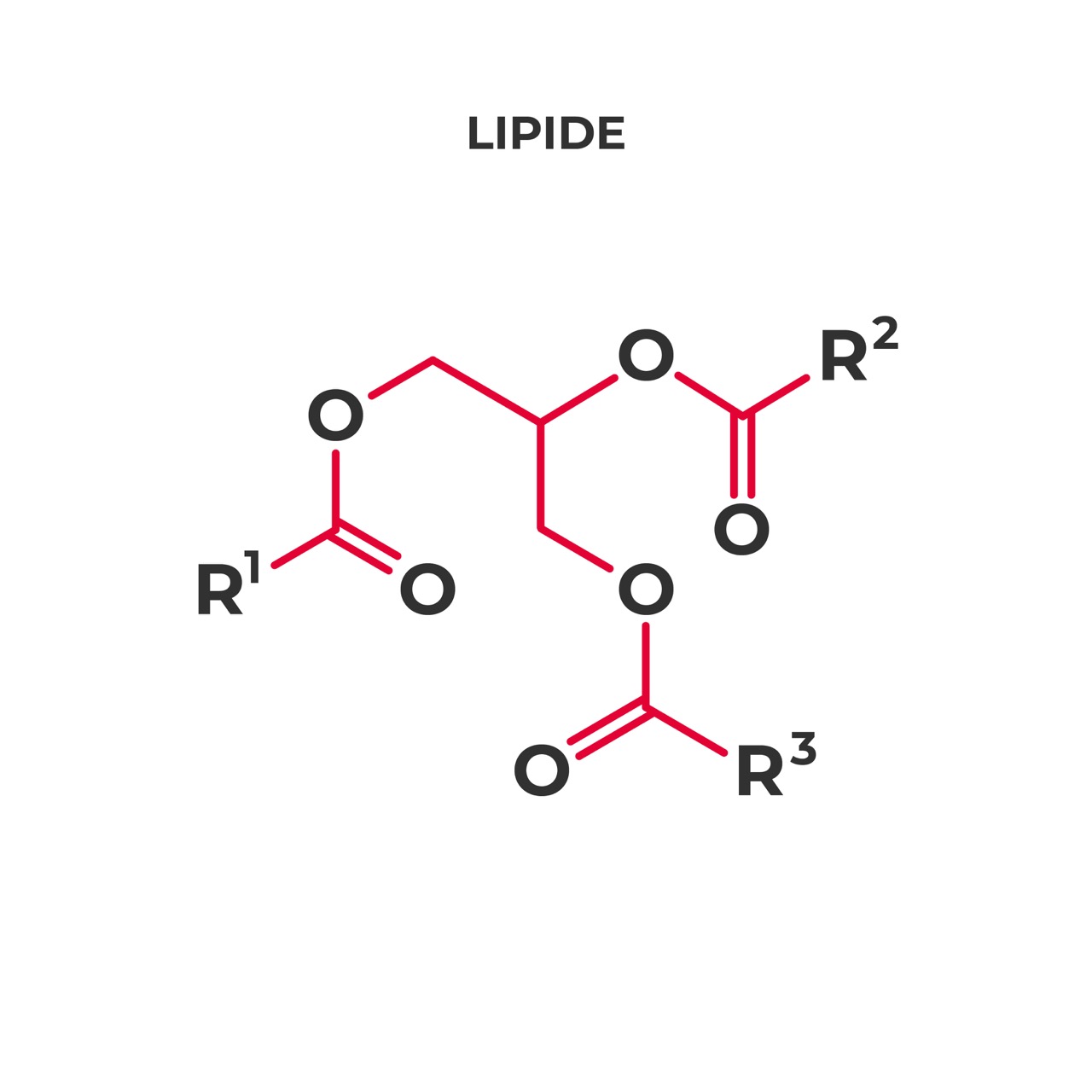

Lipide

The raw form of lipide are not polymers. The oleo chemistry, an oil specified chemistry branch, knows ways to process oils into polymer intermediates or end products. Through hydrolysis, transesterification, saponification, or hydrogenation natural occurring lipide can be processed indirectly or directly to bio polymers.

One very popular example of a bio lipid is the ricinus/castor oil. This oil is gained from the seed of the “magical tree” ricinus. More than 75% of ricinus is ricinoleic acid. By a multiple-step chemical reaction, the ricinoleic acid can be produced to the raw material polyamide 11 (also known as nylon 11), which is high-performing plastic especially for the footwear industry.

Now since you have an overview of the natural polymers, the next articles will explain more about the impact, processing and usage of those green materials.

To give you a sneak peek, see the picture of a cork material sample.

If you liked this article, make sure to follow our Social Media channels. You can contact us anytime via LinkedIn, Instagram & Facebook. We are happy to receive any feedback and tell us what other topics are of interest to you. We will try to address them in the near future.

Thanks for checking out our blog!