Shoelast · Basics

Introduction

Almost every shoe development starts with it. It gives a shoe the final form and is still formed out of wood in Germany. Can you guess what this article will be about? We want to tell you more about the shoelast!

Navigation

What is a shoelast and why do we need one?

Wood vs. plastic

Measuring a last

Different last categories

Making of a last

Production

What is a shoelast and why do we need one?

Wood vs. Plastic

The base model of each shoelast in Germany is produced out of wood. White beech is generally regarded as the preferred wood to work with. Cutting, carving, creating sharp lines and transition from filler to wood is smoother.

Although because of the humid climate, wood is not suitable for the development process in Asia where HDPE (High Density Polyethylene) is the material of choice.

Still in Germany as well as in Asia production lasts are made out of HDPE.

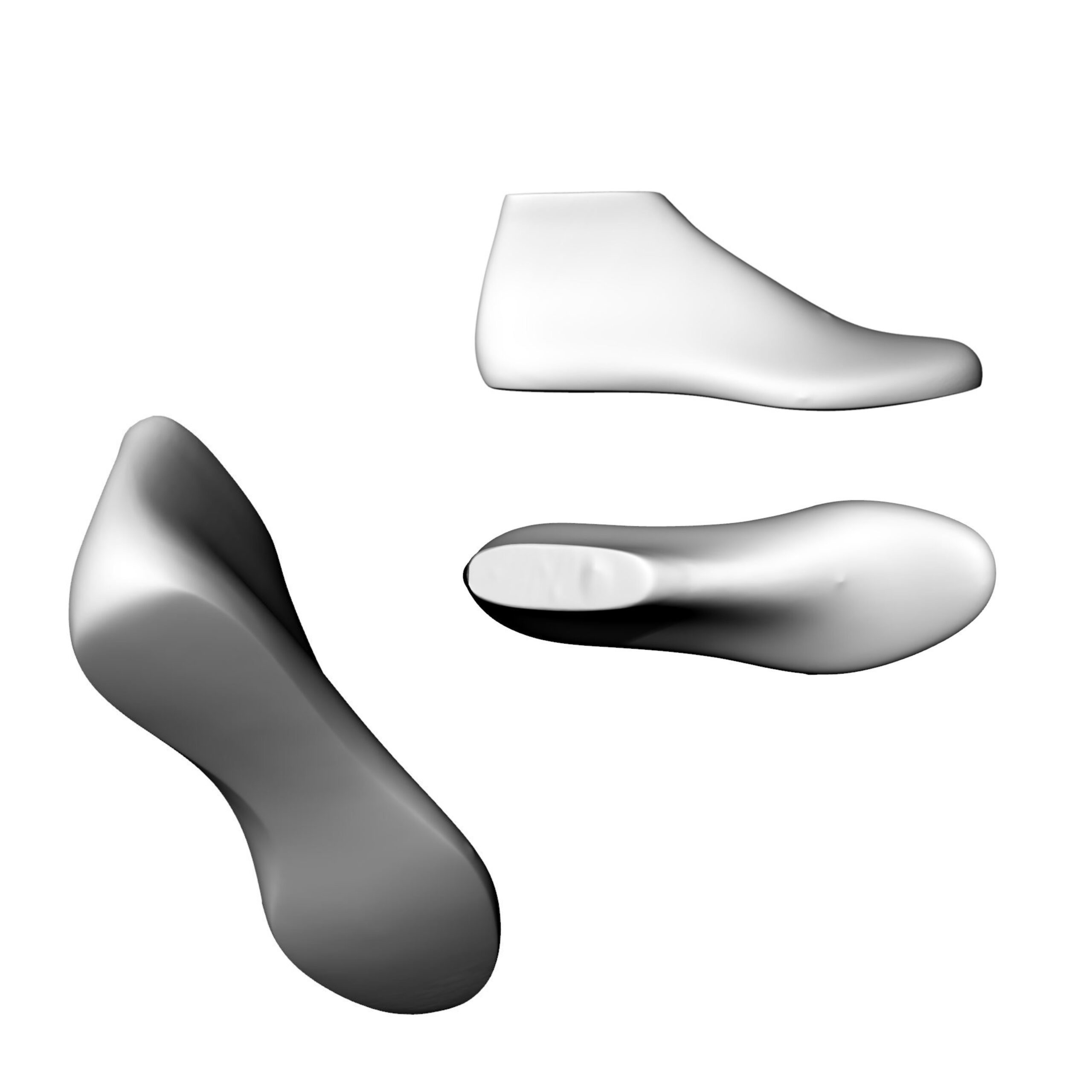

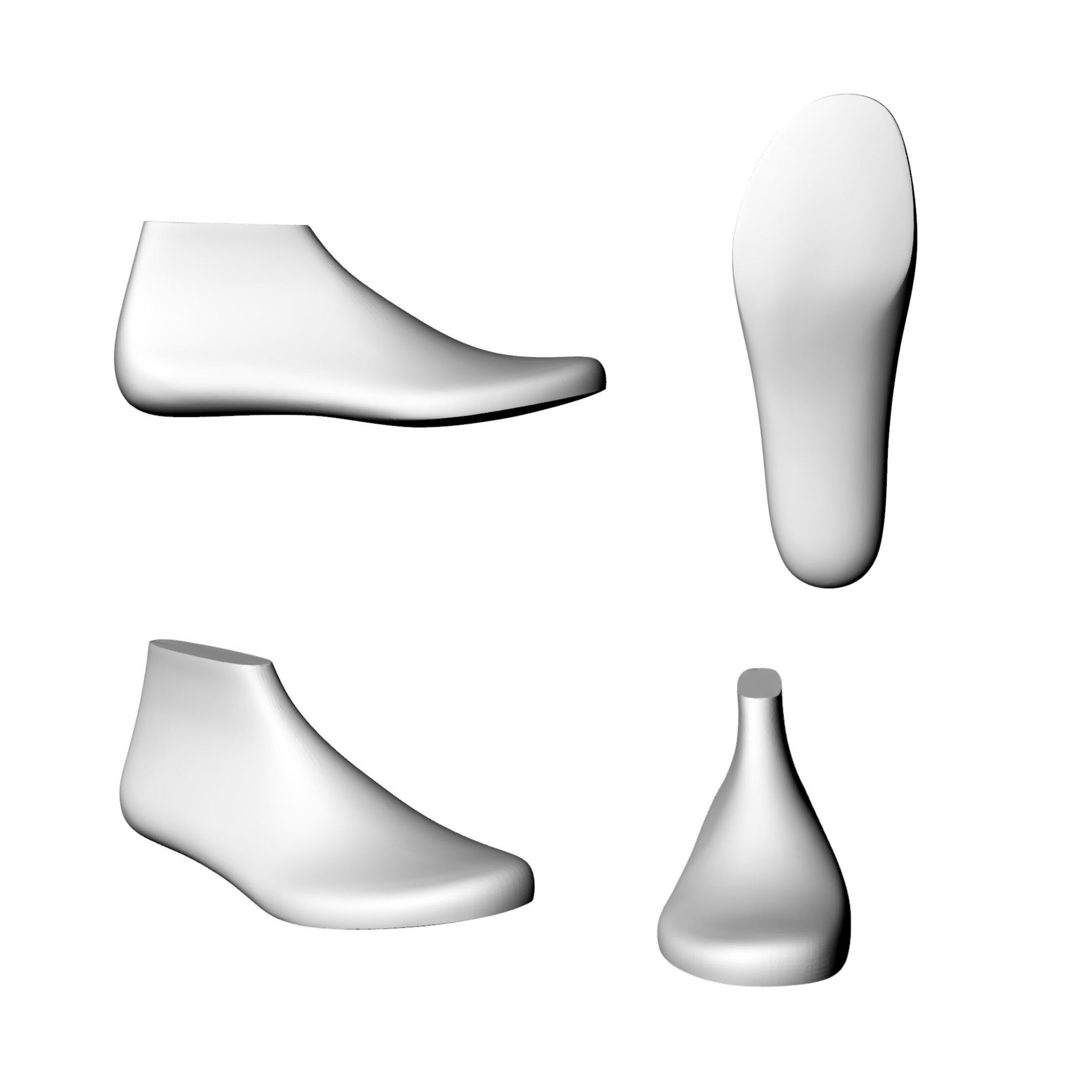

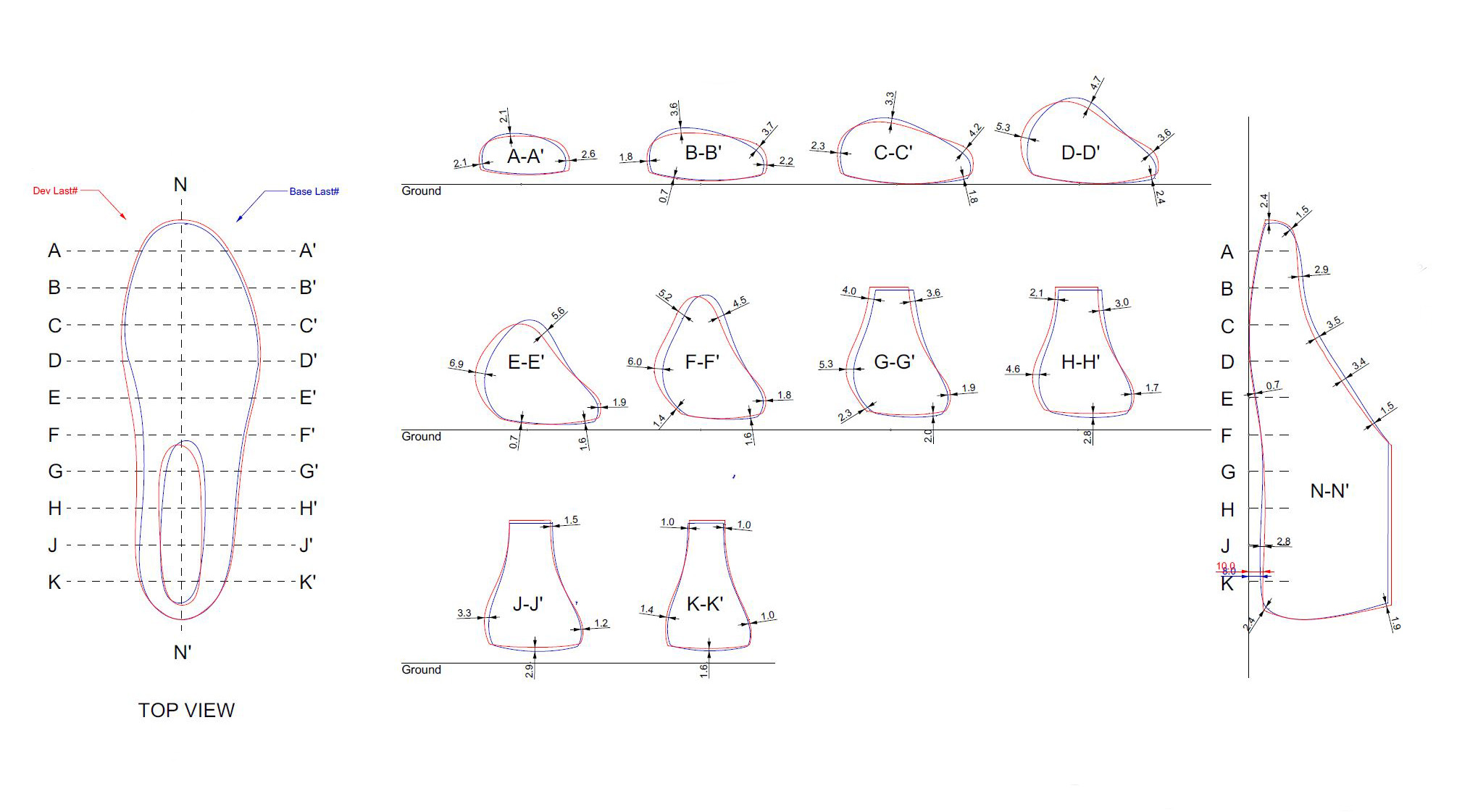

Measuring a Last

There are different points to measure a last and to make sure that it was manufactured according to standards of the different sizes. The most important ones are marked in bold right next to the pictures below.

Main Measurement Points

Stick length

The stick length defines the widest point in the length of the last.

Ball width

Defines the widest point in the ball area and is measured with the help of a caliper.

Instep girth

The measurement of this point guarantees that the foot fits into the later shoe.

Ball girth

Is defined as the volume around the last in the ball area. This point can only be compared from last to last and not from foot to foot, because each foot is individual.

Heel Spring/Toe Spring

Tells more about how the last is positioned in the later shoe and helps in the different categories.

Main Measurement Points

There are different measuring tools for controlling different points of the last.

A caliper is used to measure the stick length, the back cone height etc.

Measuring tape is used to define the ball girth and the last bottom length etc. and a ruler is needed to measure the toe spring.

In addition, heel blocks (metal plates) measure the heel spring. The PFI gauge is used to mark the ball girth position.

All measurements are noted down in the so called “Specification”, which is forwarded to the customer after the last development. With the help of the specification the customer can orientate his production settings.

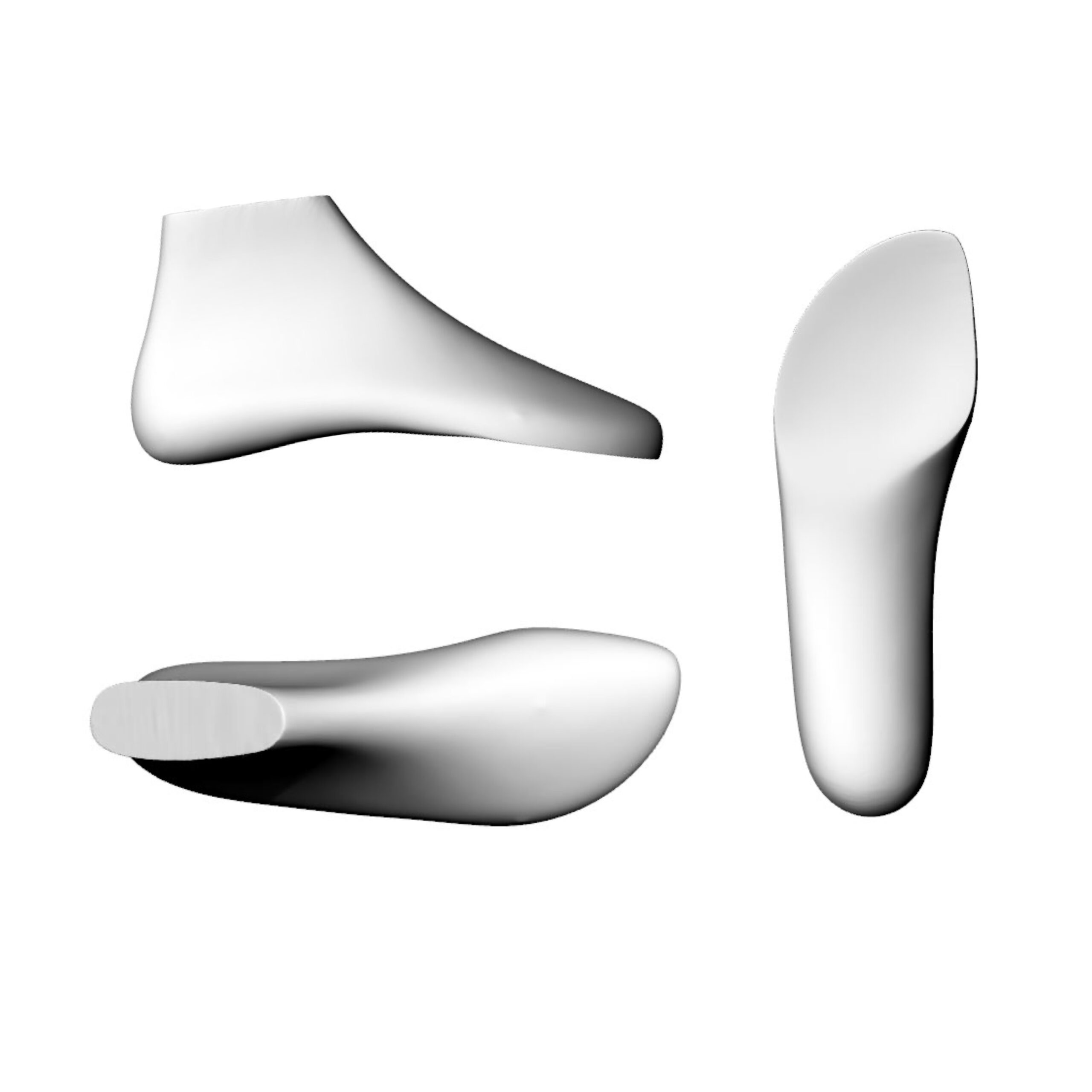

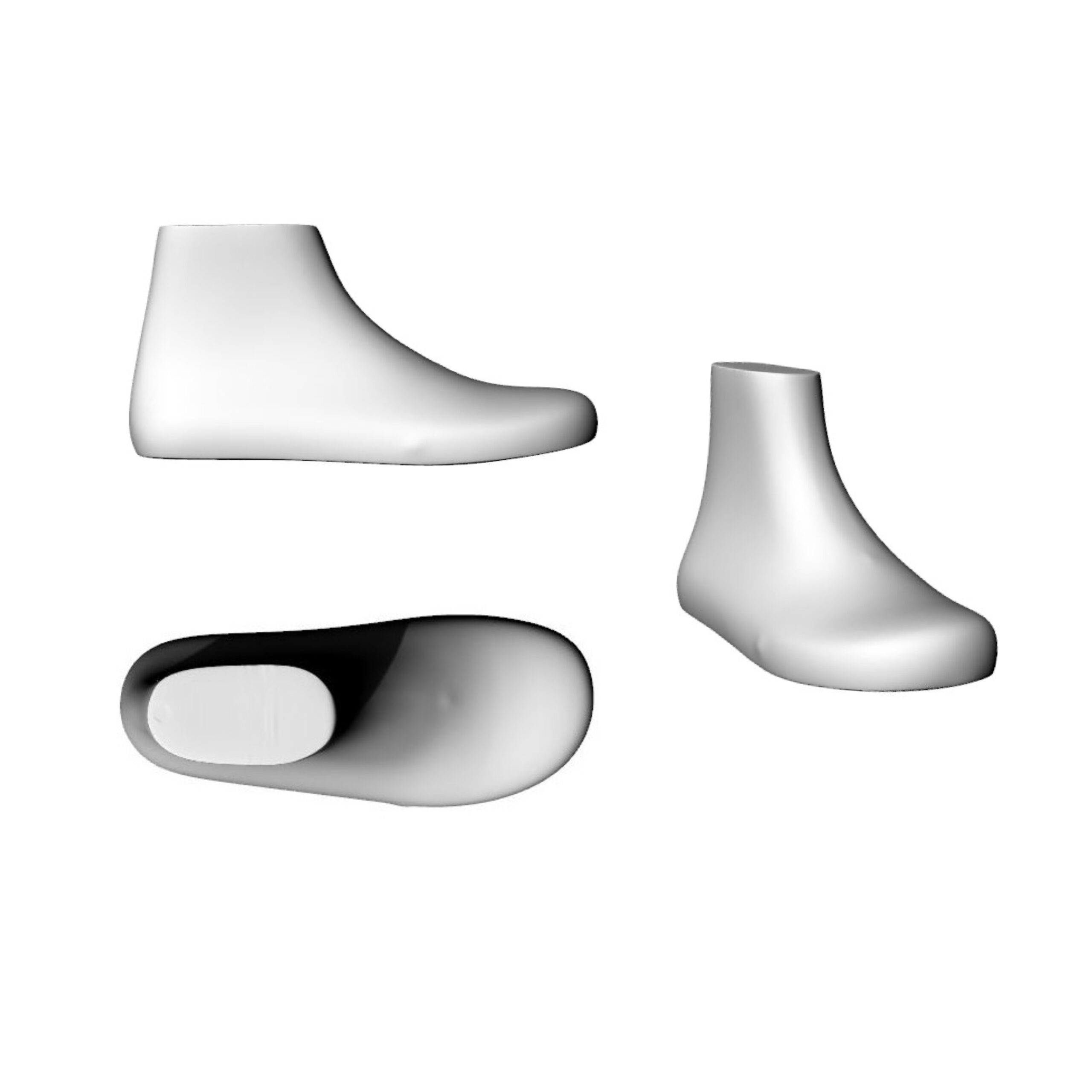

Different Last Categories

Depending on the category of the shoe, the last is built for, there are different specifications the last must fulfill.

Football

A football shoe needs to sit tight on the foot. Therefore, a last for this category must have a narrow heel clip, a slim forefoot area and arch.

These functions provide extra stability for the whole foot and give a better connection to the football. As well the side walls of the last are rounded which makes it easier to handle the football. A football shoe must be comfortable as well because the players run a lot.

Running

Running lasts need a balanced heel to toe spring ratio for a better roll up. Most running lasts have an asymmetric toe shape, which is adapted to the anatomy of the foot. This gives the foot sufficient space at the right place.

Also, it has a wide forefoot area. This is because the foot can be swollen during or after running and should not be put under pressure. Quite often they also have a rounded heel, so the shoe adapts to the anatomy of the foot. In addition, running lasts have a narrow heel clip to avoid the foot slipping out of the shoe.

Spiked Running

A spiked running shoe has similar properties to a normal running shoe. Those shoes are used for short distance running. In addition, they also have stiff outsoles. Therefore, the toe spring in the last is raised which makes the power transmission on the forefoot easier.

To compensate the burden on the forepart special attention to the medial and lateral balance must be paid. The slim back part gives an extra stability, so the foot is not sliding out of the shoe.

Safety Boots

For safety boots the volume in the toe area is shrinked so the later toe cap fits. The side walls are high to adapt to the later boot shape. In general, the properties are like those of a hiking boot. The instep area is kept wide with attention to the later shoe construction e.g., zip, lace, slip on.

These lasts have a lot of volume to compensate for thick materials, foot beds and water resistant membranes. In addition, people often wear thick socks in their safety boots.

Fashion

For fashion lasts it is hard to define any fixed standards because, as the category suggests, they are built according to current fashion trends. It is not uncommon that a shoe, originally from another category gains prominence in the fashion industry.

Normally the back part is standardized but aspects such as toe depth, shape and the overall length of the last can vary.

Climbing

Climbing shoes have an extreme tight fit, a curved arch and forefoot. The toe area is asymmetric with point over the big toe. This is done because the big toe is the most powerful toe. The big toe can hold the entire body weight for several seconds, which is often required when climbing.

Children

The properties of children lasts can vary for certain age range groups and categories. It is crucial throughout all categories, that enough room is given to the growing feet with all areas carefully considered.

Also great attention needs to be paid to the toe spring, which should not be too low. The bones in children’s feet are too weak to properly roll their foot and would fall. The fitting is extremely important because otherwise it is possible that the foot can be deformed.

Sandals

Sandal lasts are produced closer to the real foot length and still the bottom is rather wide because of the spread of the foot during walking. They have slim, low sidewalls and often a sculpted bottom for the molded footbed. The toe depth does not play a role in this category because it is open.

Making of a Last

Development

In the development process, there are three commonly used methods to start the process.

Base last

The footwear developer aims to produce a new shoe which uses another model as the base – the so-called base last. This is the most used method. With the help of the base last not every new development needs to start from scratch. Rather a completely new shoe can be created with changes on an existing last.

There are different use cases in which this development method is needed e.g., the footwear developer would like to produce the same shoe, which is already on the market, using a new material. Or the production is changed from Strobel to AGO (If you would like to know more about these production methods, be sure to check out our blog post about heel counters.)

Design

Brand Designer send a rough idea of a new shoe. A meeting is then scheduled to discuss materials, exact form, and function. Afterwards the last is created.

Reference Shoe

The last method is working with reference shoes. The shoe developer gives the last manufacturer different shoe models which account as reference shoes. The new model should be a mix in design of the reference shoes. The fit is defined by the shoe developer.

The data is then transferred and a wooden base last is milled. On these last further changes can be done.

Digitalization

Model confirmation & alterations

Traditionally lasts were confirmed by eye, but with the aid of CAD, comparisons can be made from version A to B. This leads to a better control and visibility of alterations.

CAD can as well be used as a tool to make minor adjustments, but it‘s not capable of creating what the experienced model maker can with the last.

Fully graded last

Measurement is taken from stick length and ball girth. This value is graded up and down freely using the appropriate grading system. The most commonly used systems are the British, American and French one but they can also be customer specific.

Coordination grading

Specific areas of the last stay stable, allowing the rest of the last to grade naturally e.g., stick length.

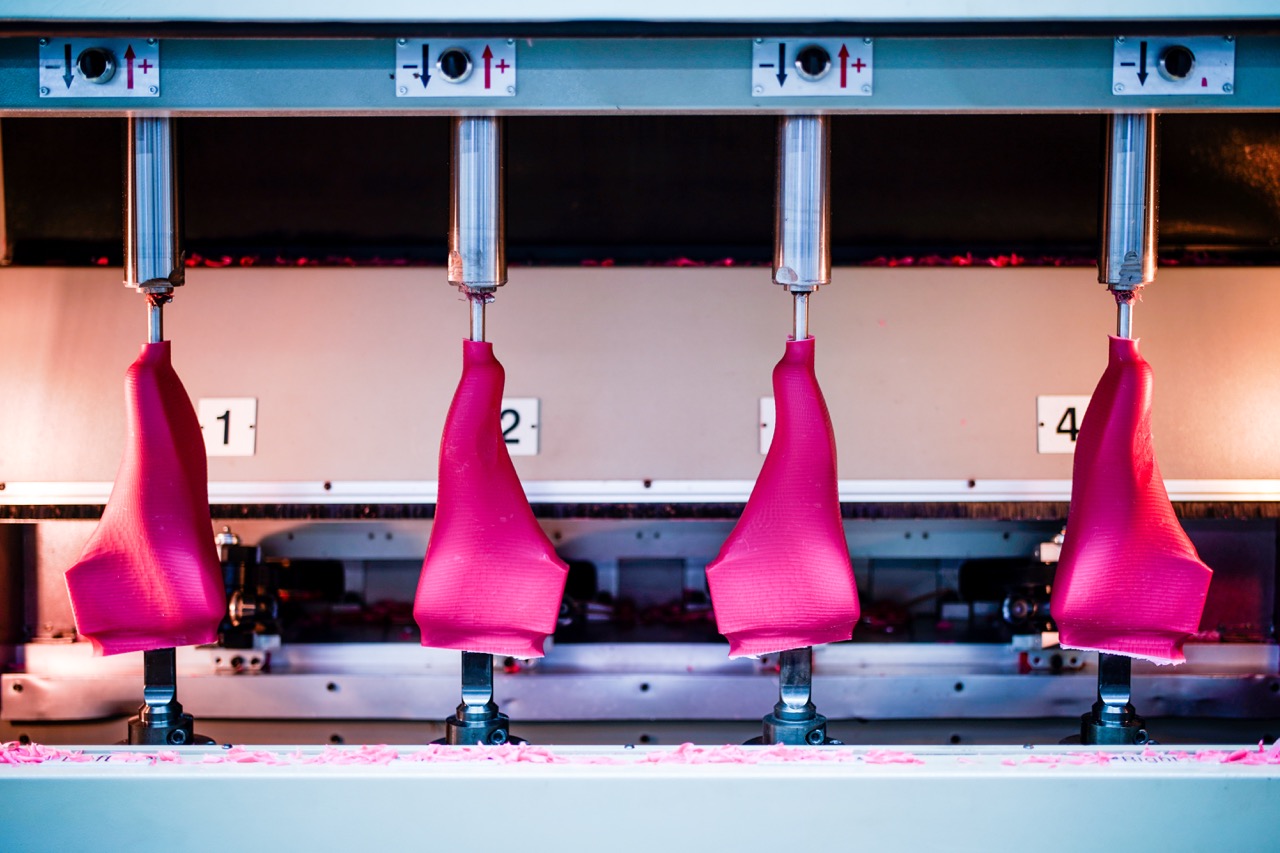

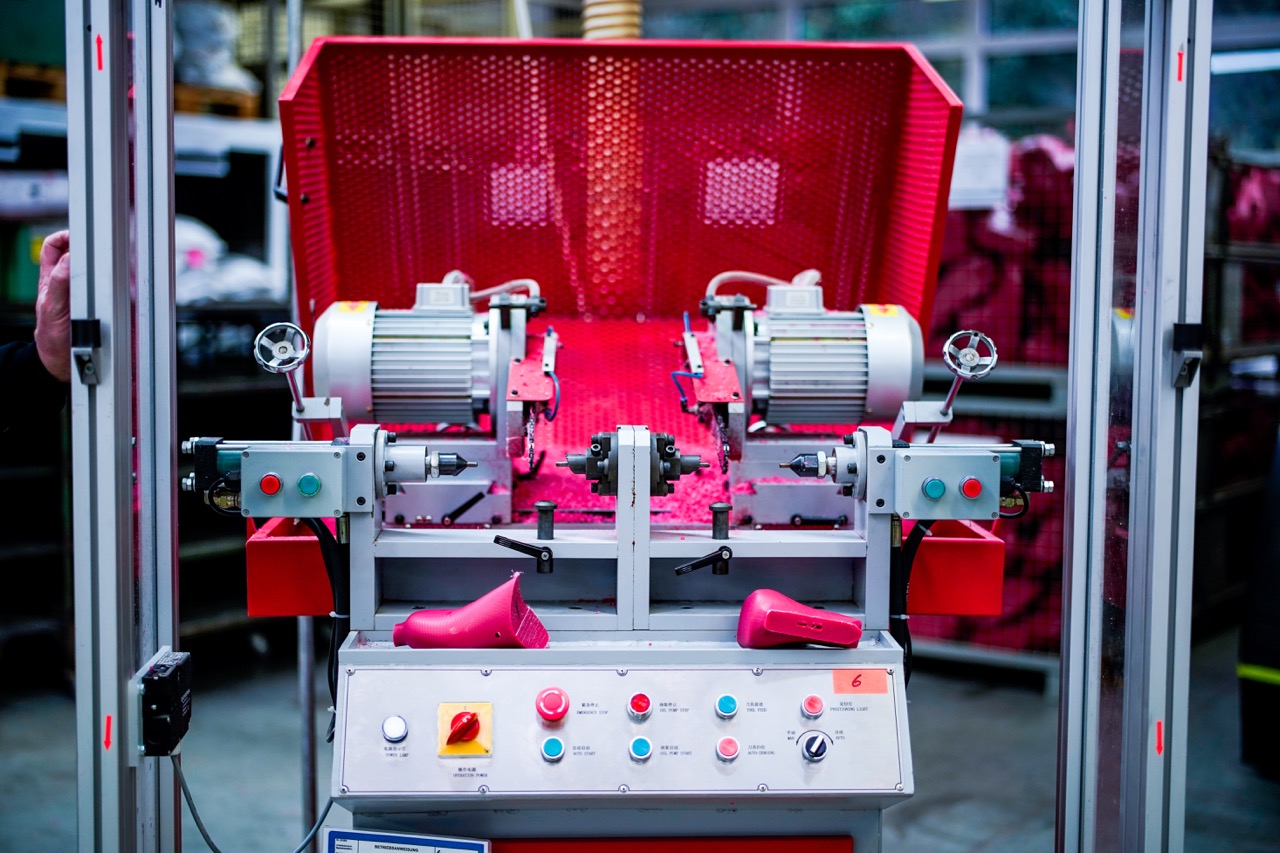

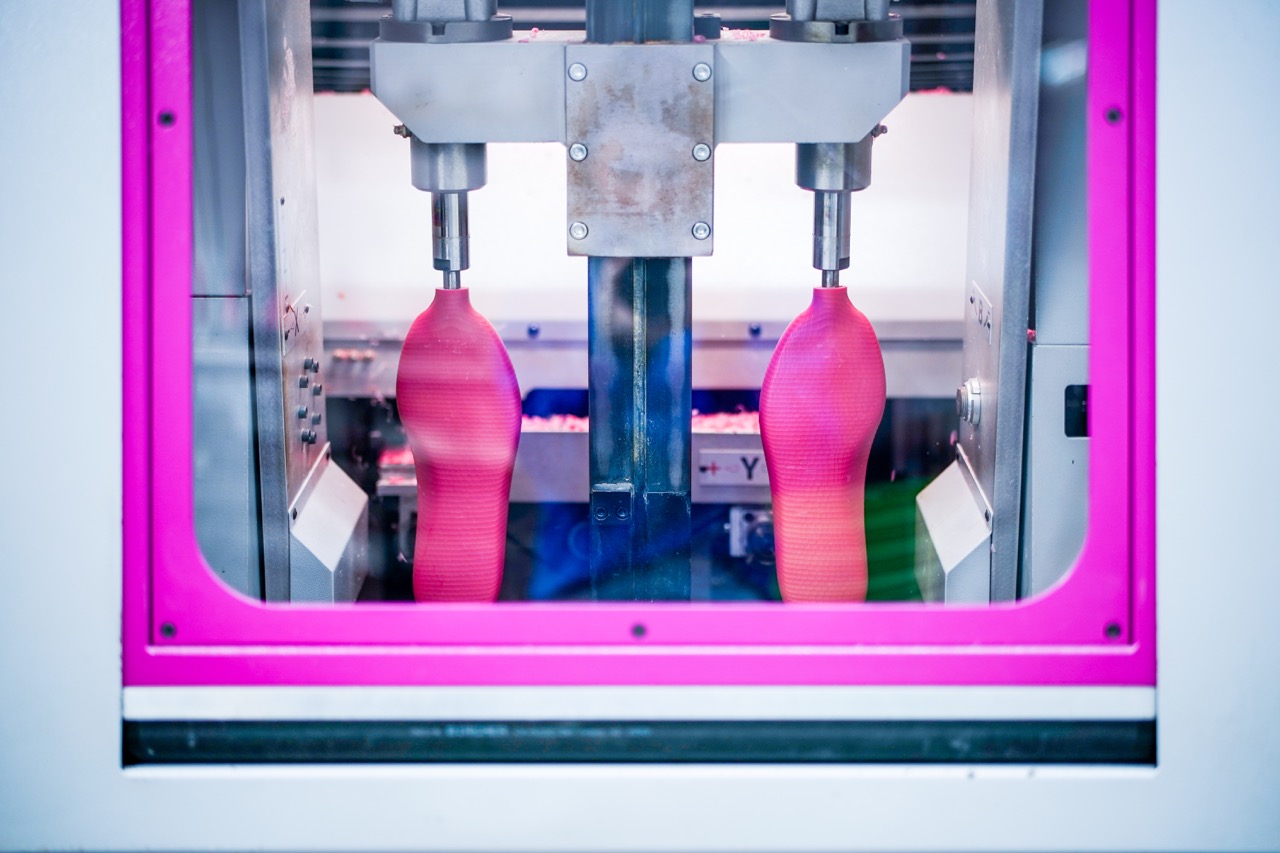

Production

Production Last Material

The basic material of these lasts is High Density Polyethylen (HDPE). It belongs to the group of polyolefins. Polyethylene is a semi-crystalline thermoplastic produced by polymerization of ethene. The melting point lies at 120°C.

At framas all normal production lasts are produced using HDPE. This plastic withstands humidity changes and is strong enough to endure the varying types of processes and pressures during the production process.

Basic Production Process

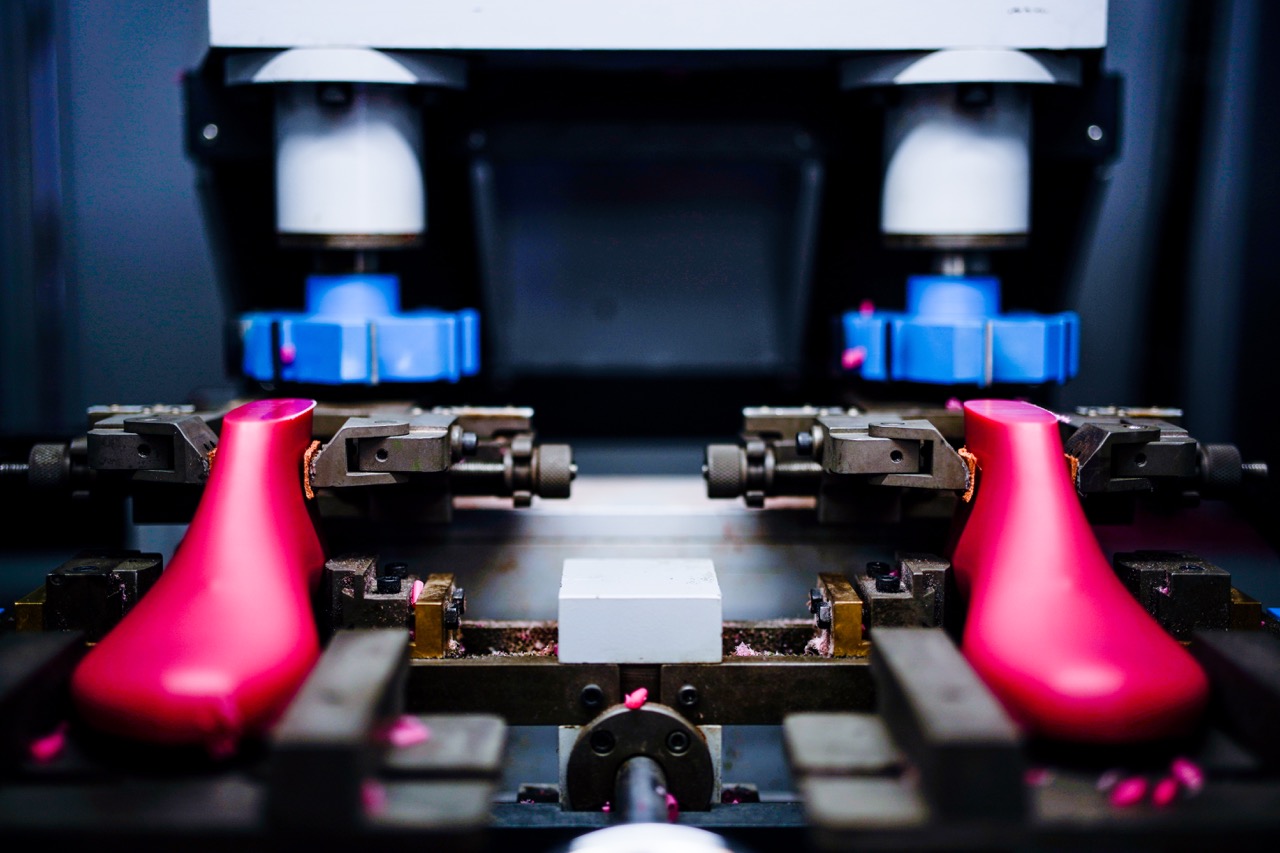

The last block is first rough milled to shape, attached to the machine at the toe and heel part.

At this time a system for easier delasting process e.g., last with vertical hinge is included.

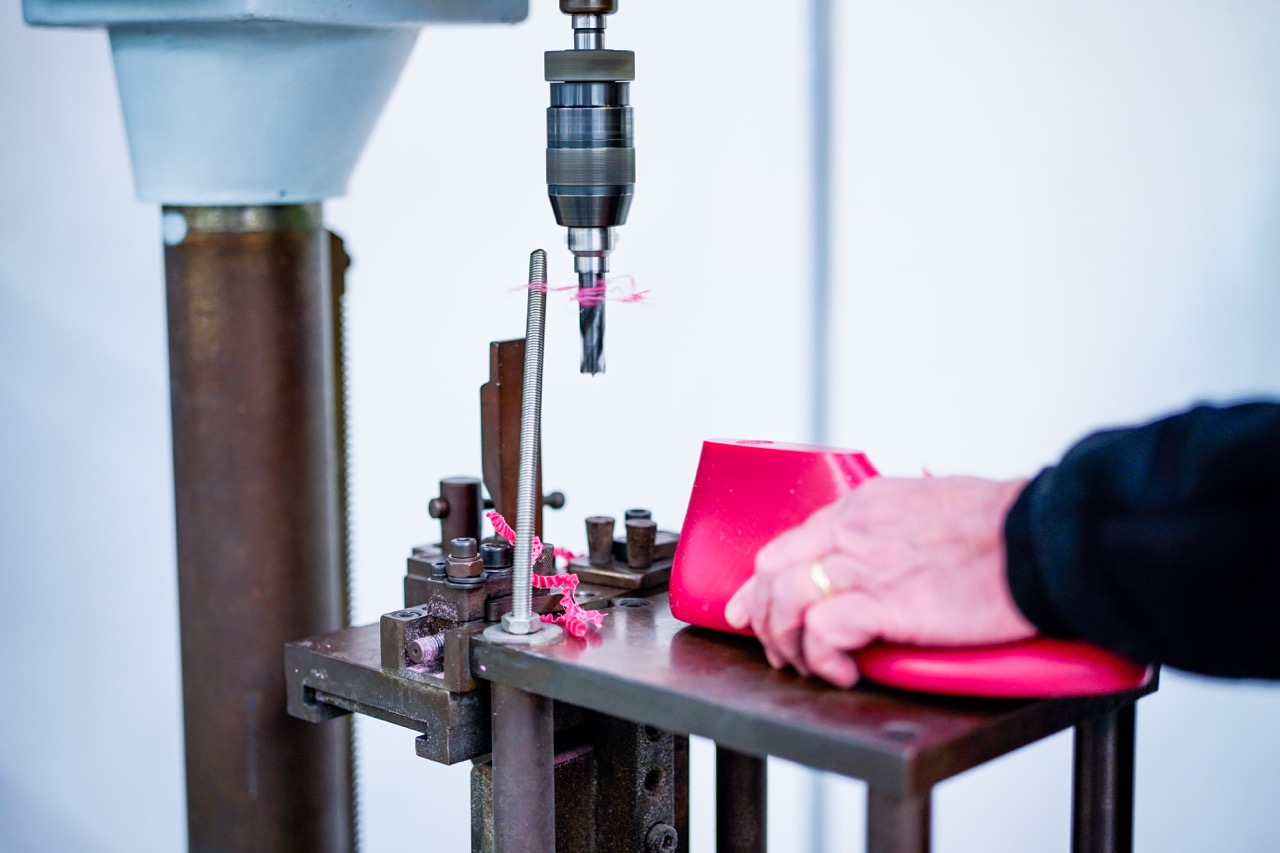

Firstly, holes are drilled at specific locations for the hinge pins.

Following cuts are sawn with an exact radius for optimal hinge movement and length reduction.

In the next step cuts are also made inside the last to accommodate the hinge location.

At this point the basic production process continues and is the same for every last.

The comb holder is milled in the last, which is needed to hold it in place in the coming machines.

Afterwards, the back and front of the last, which were previously needed to hold it in place, are cut off.

The last is then fine milled to achieve a smooth and precise finish.

In the next step the stick length is measured with the help of a caliper. In addition, a measuring tape is used to define the ball girth.

After that the fine milled last is cut to the correct production back cone height.

The surface of the last is then burned to give it a shiny, polished look and to improve the detail of the laser marking.

The last is afterwards marked with a laser, which typically includes the company logo. Depending on the customer’s preference, different stamps such as production date or last number may be added.

A hole is drilled into the last to accommodate the socket, which is needed for later positioning of the last in the production machine.

The socket is inserted into the hole, which allows for secure and precise positioning of the last in the production machine.

Further Processes

At framas Germany the produced lasts are only used as reference model, archive pages and small series for European production. The main production of lasts happens in Asia with our partner YinHwa.

After production the lasts are then sent to the customer for further testing, processing or directly to the shoe factories, where they are used for production.

If you liked this article, make sure to follow our Social Media channels. You can contact us anytime via LinkedIn, Instagram & facebook. We are happy to receive any feedback and tell us what other topics are of interest to you. We will try to address them in the near future.

Thanks for checking out our blog!

Neueste Kommentare