Material Basics · Injection Molding

Material Basics · Injection Molding

09.12.2022 · Expert Sebastian Wendling / Editor Luisa-Maria Mrcela & Jakob HellgrenInjection Molding in the footwear industry

The range of plastics is huge. To not lose track, in this blog we focus on plastics used in injection molding within the footwear industry. But first of all, what is injection molding?

Injection Molding is a commonly used manufacturing technology in the footwear industry. In this technology a thermoplastic material is melted into a liquid, either rubber or plastic, injected into a mold and then cooled down. The mold is determining the final 3D-shape of the component e.g., outsole.

Navigation

What is plastic?

Synthetic polymers · Four different groups

Thermoplastics in injection molding

Thermoplastic Polyurethan (TPU) – The star of the thermoplastics

Polyamides (PA) – The stiff ones

Polyether Block Amide (PEBA) – The luxury one

Styrene-Butadiene-Styrene (TPS-SBS) – The biggest group

Summary

What is plastic?

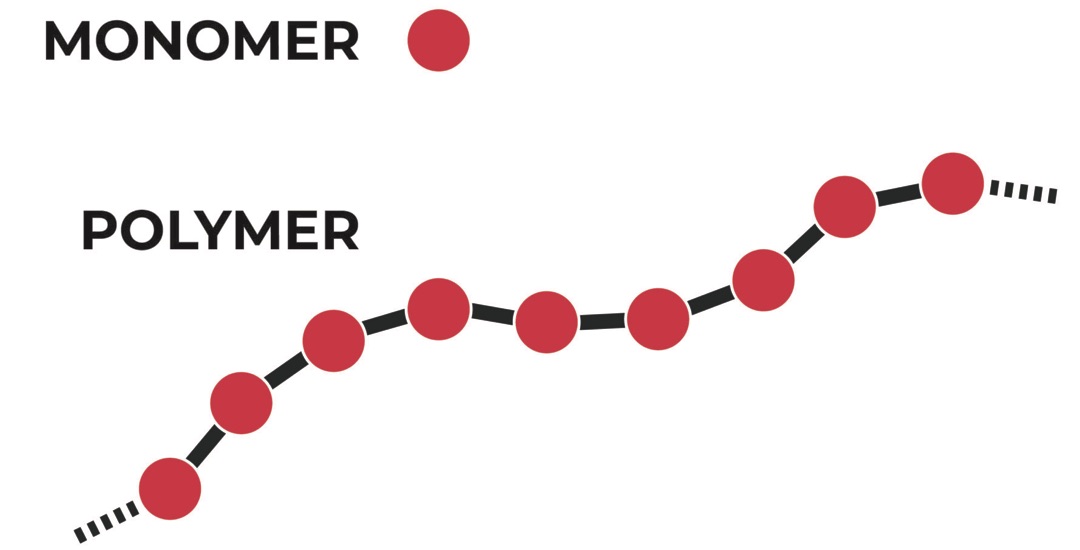

And now continuing with some chemistry: The correct chemical term for plastic is polymer. The word polymer comes from the Greek prefix polý-, which means „many“, and the suffix -méros, which means „parts“. Polymers = „Many parts“.

Polymers are giant molecules made up of chains or rings of linked repeating subunits called monomers.

- Cellulose

- Cotton

- Wool

- Amber

- DNA

- Natural rubber

- Starch

Synthetic Polymers

- Polyethylene (PE)

- Polypropylene (PP)

- Polyvinyl chloride (PVC)

- Polystyrene (PS)

- Polyamide (PA)

- Polyetherblockamides (PEBA)

- Thermoplastic styrene elastomers (TPS)

- Thermoplastic Polyurethan (TPU)

- Polyurethane (PU)

- Epoxy resin

Synthetic polymers · Four different groups

First the bad news: Not very surprisingly, the footwear industry’s focus is still on synthetic polymers which are mostly not biodegradable. Good news, due to their melting properties, with the right idea, concept, design, and process some synthetic polymers can be the core material for real material loops.

Please do not worry, natural polymers will be payed attention to in subsequent blogs. So first, let’s have a deeper look into synthetic polymers. The “synthetics” can be grouped into 4 types – relevant for injection molding.

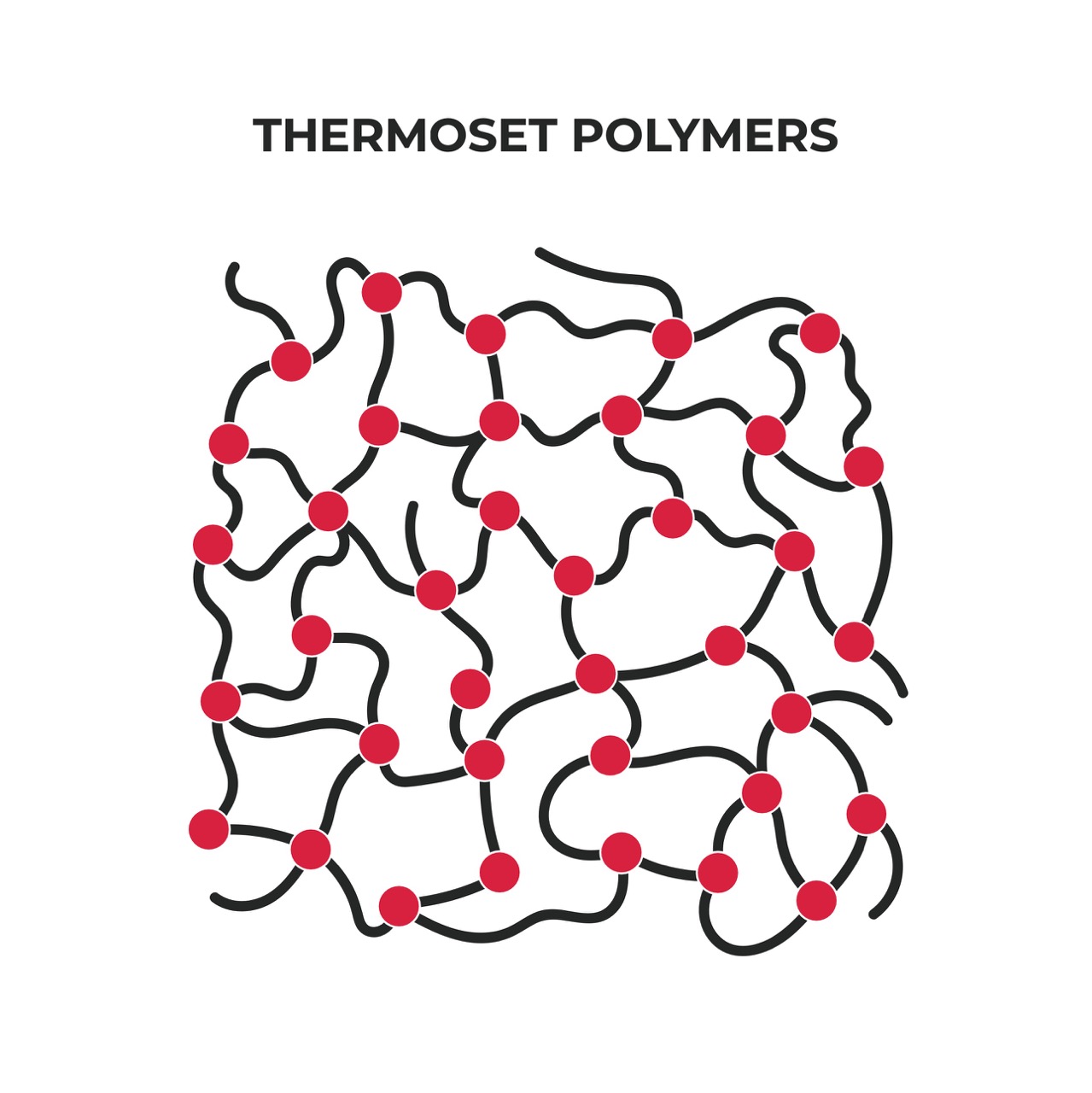

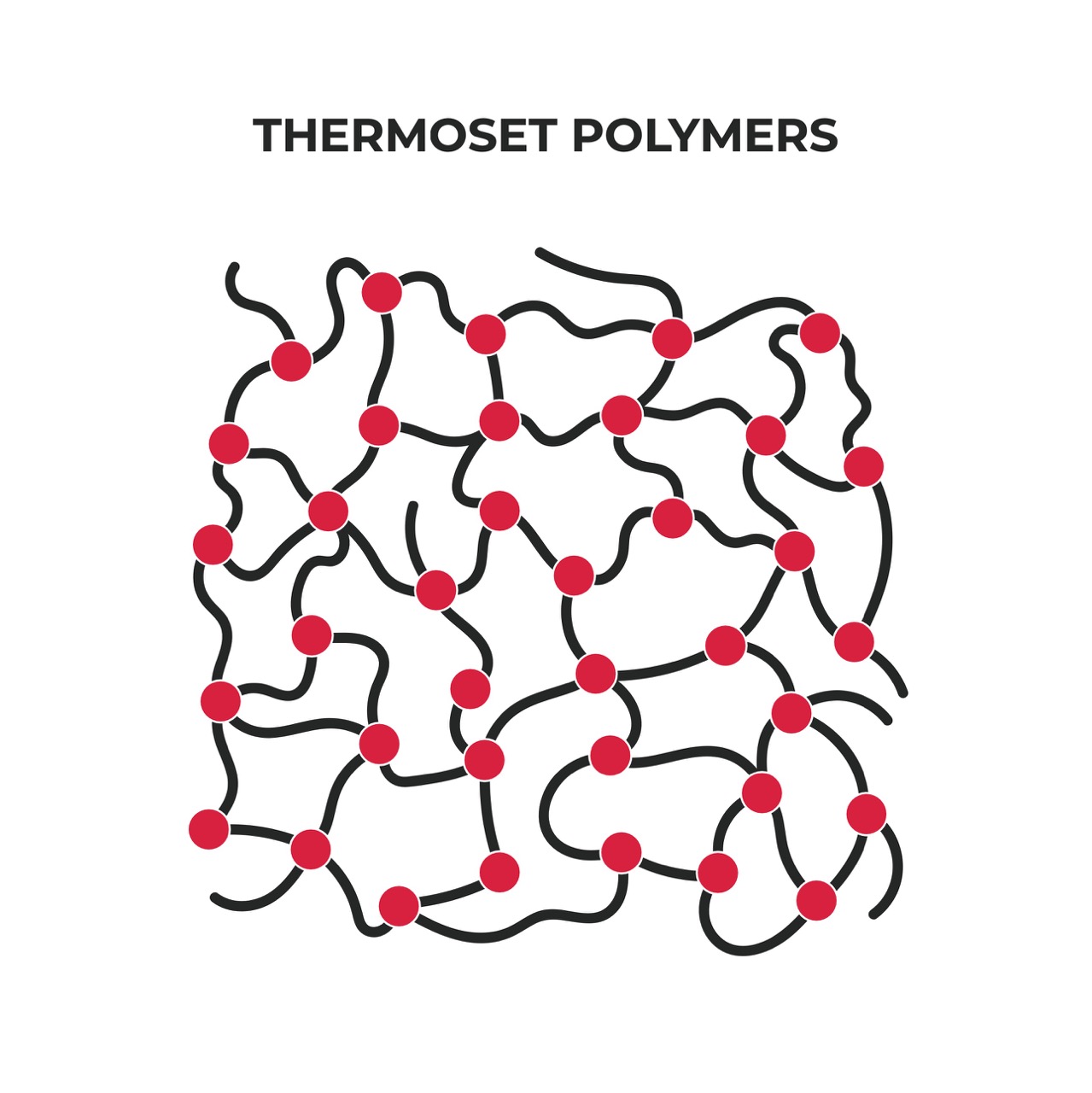

Thermoset Polymers

The first group is

Thermoset Polymers.

Its polymers become irreversibly hardened due to extensive cross-linking between the polymer chains upon being cured. (e.g.

Epoxy Resin, Polyurethanes (PU))

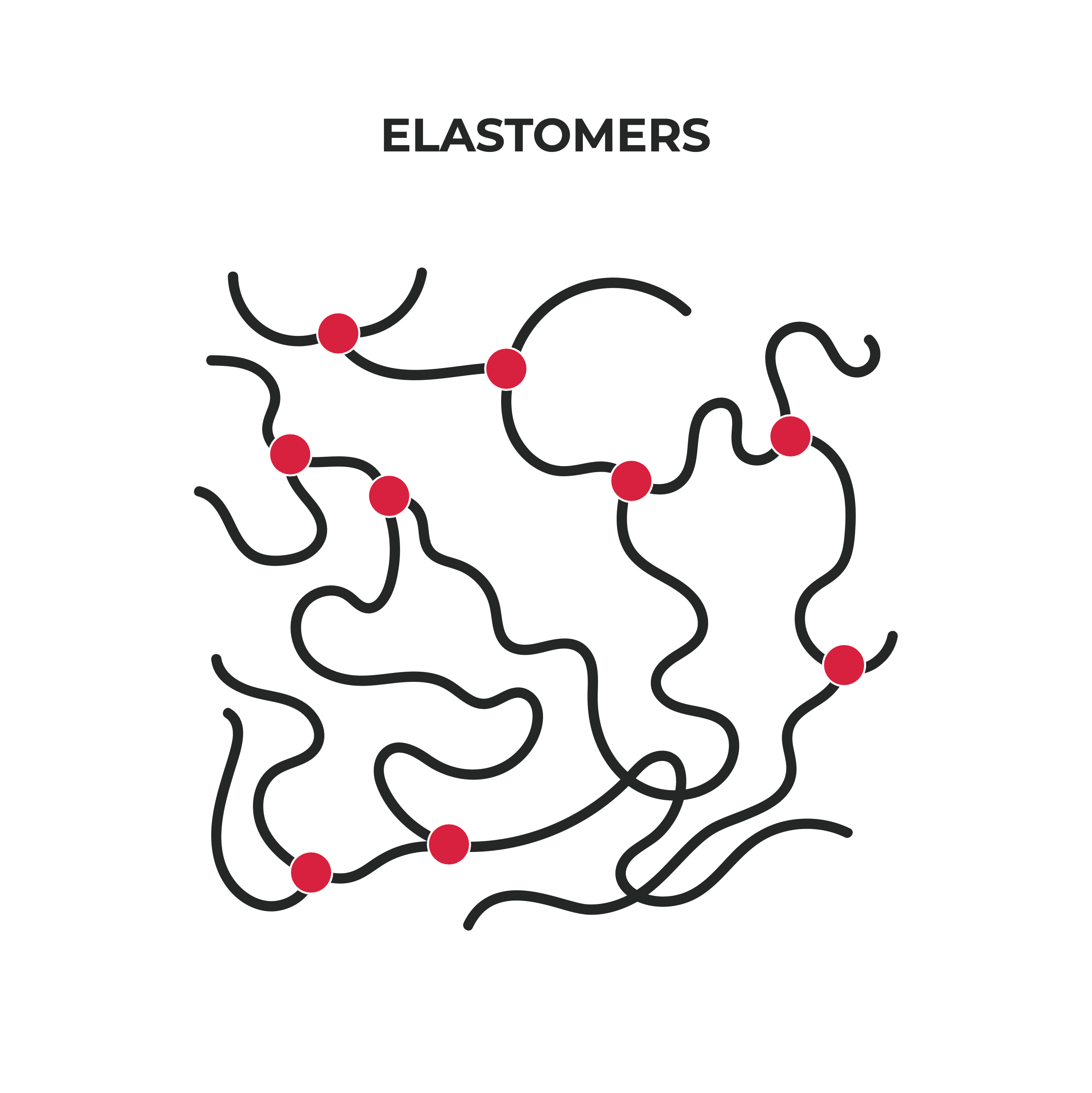

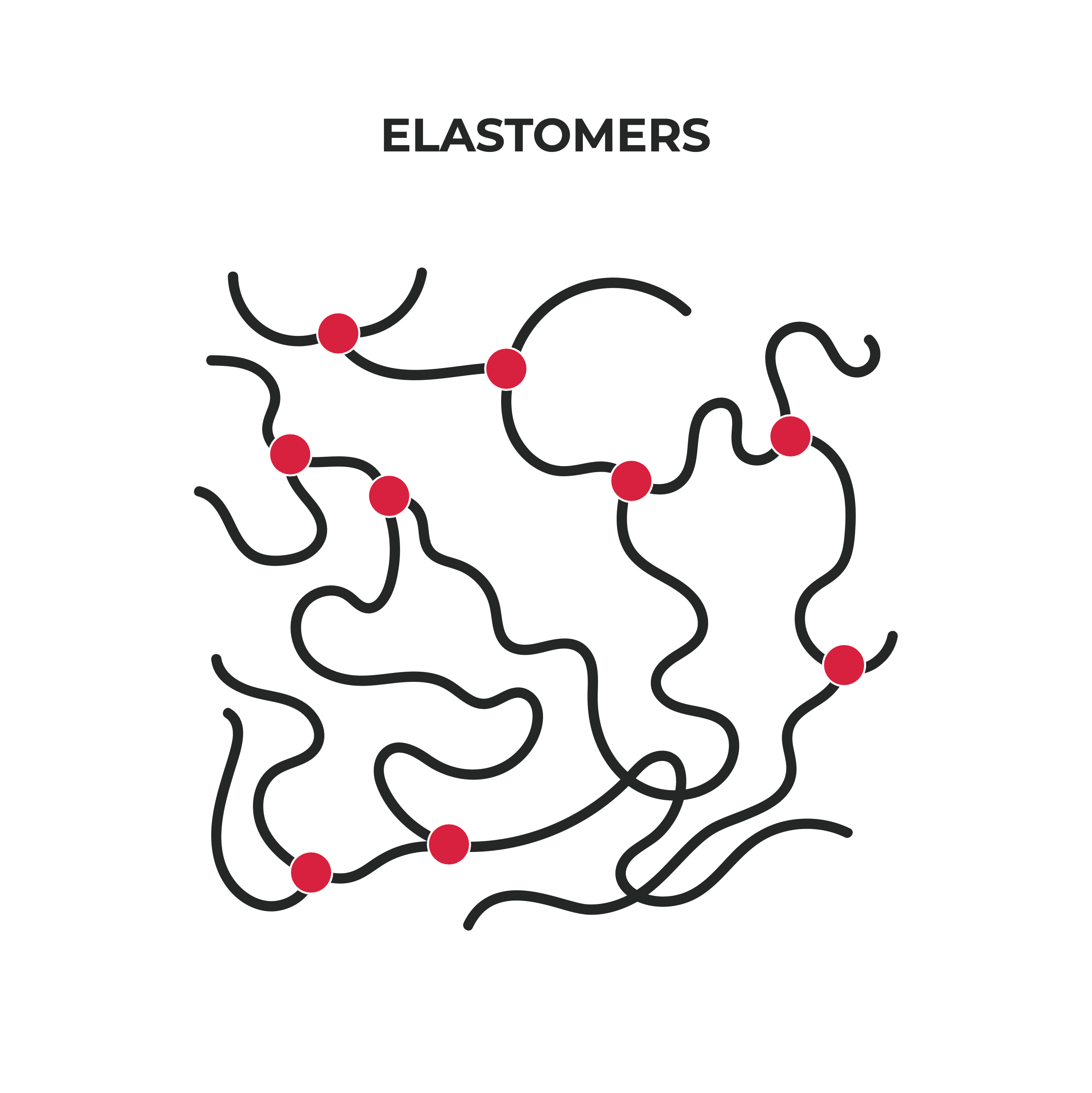

Elastomers

The second group is Elastomers.

Elastomers are lightly cross-linked and very elastic.They can be reversibly extending but the curing is irreversible (e.g. vulcanization)

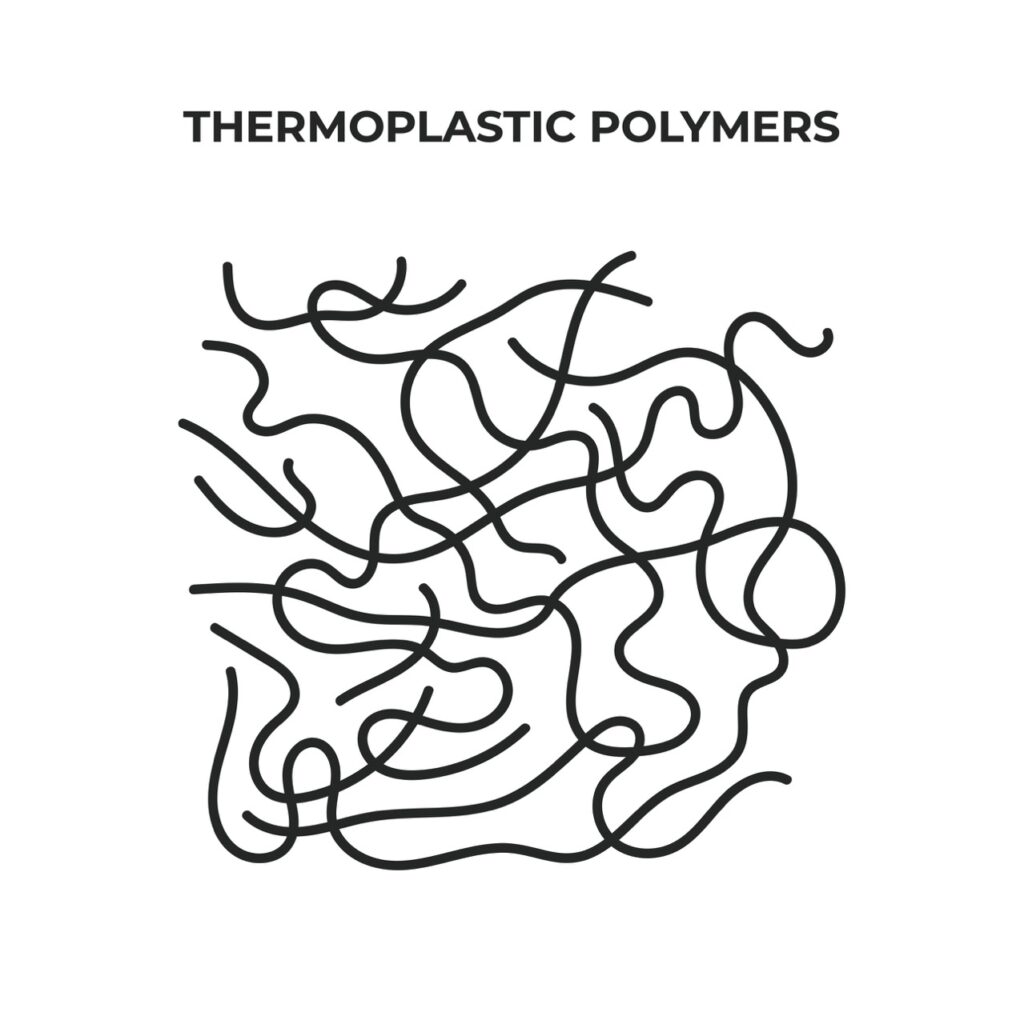

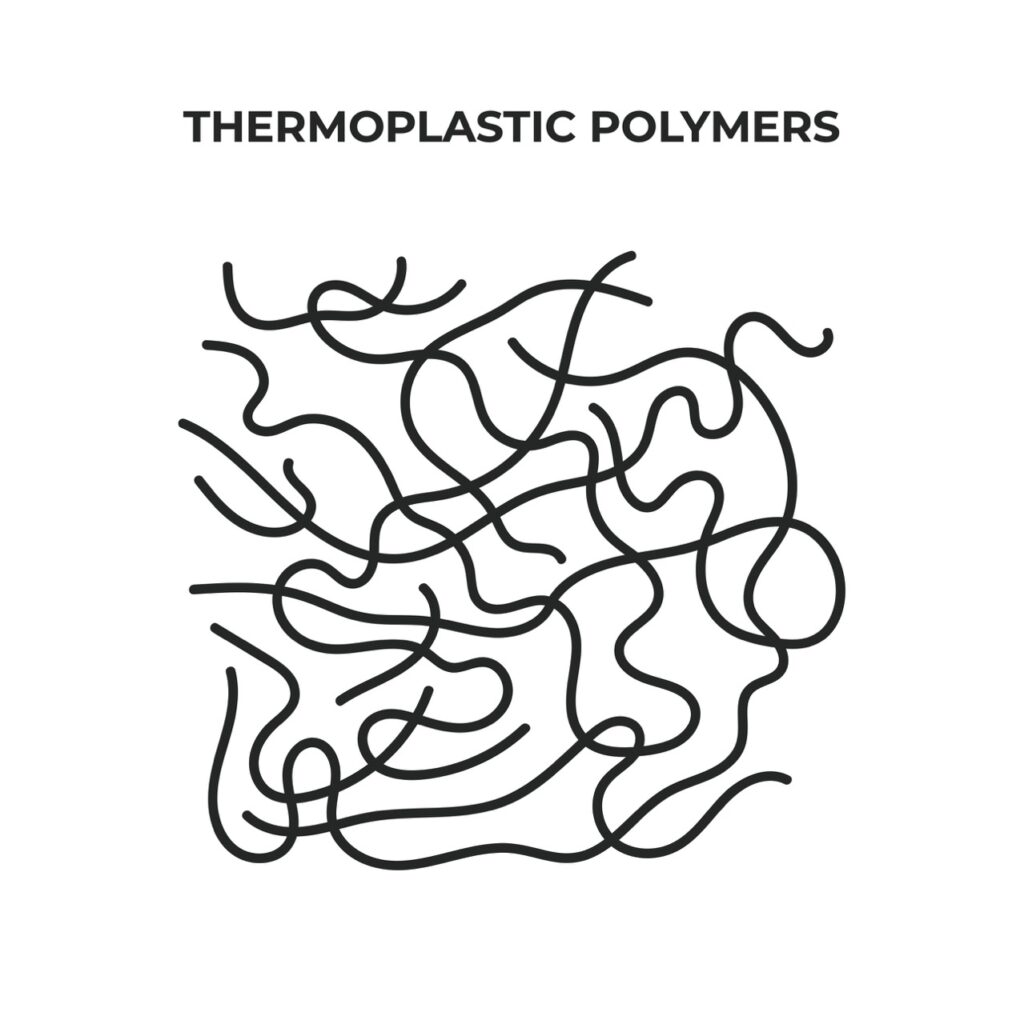

Thermoplastic Polymers

The third group is Thermoplastic Polymers.

Its polymers become moldable above a specific temperature and solidify upon cooling. e.g., PE, PP, PS, PET, PA, PC

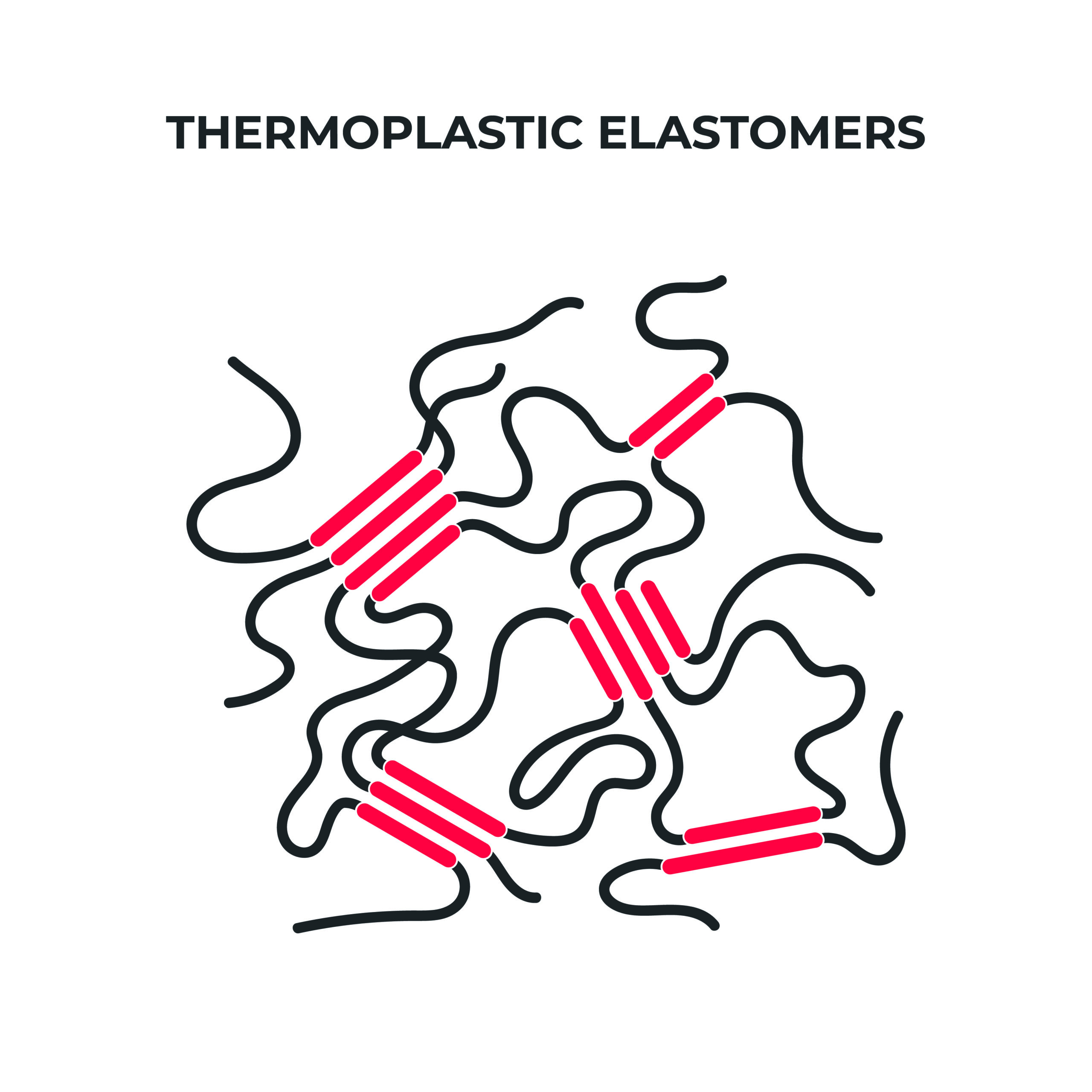

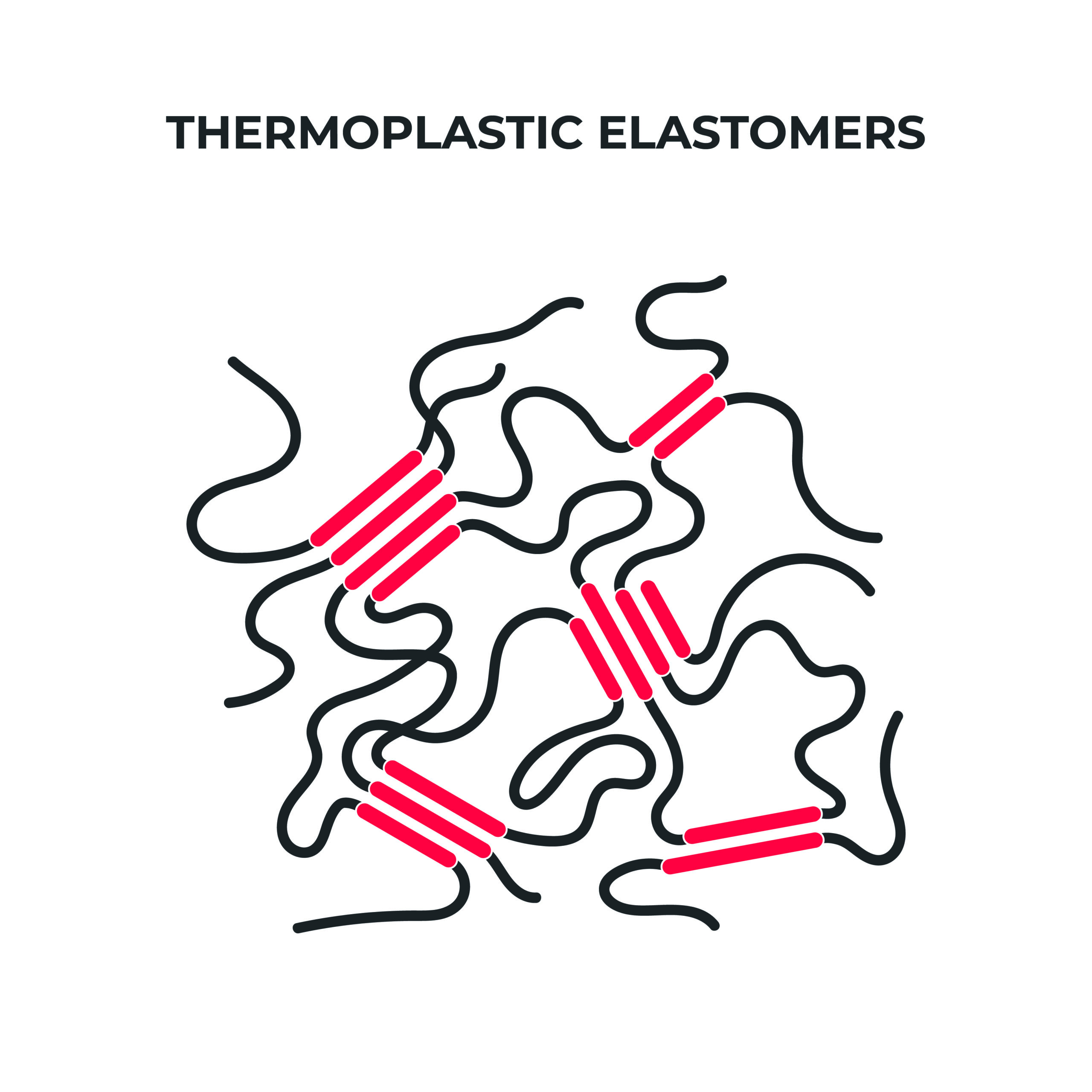

Thermoplastic Elastomers

A fourth hybrid form is Thermoplastic Elastomers.

They are a physical mix of polymers with both thermoplastic and elasto-meric properties but they are fully re-meltable e.g., TPS, TPU, EVA and PEBA

Thermoplastics in injection molding

Now you know everything about the different polymer groups, but which of those are now used in injection molding? The answer comes here. Due to their flexible characteristics the two groups of Thermoplastics are perfectly right.

When thermoplastics are heated, they melt to a liquid which makes them suitable for the injection molding process. These materials can be cooled and heated several times without any change in their chemical structure. Moreover, depending on the desired injection parameter only minor changes in the mechanical properties, e.g., colder molding temperature, are needed.

In essence, Thermoplastic is suitable for mass production of components because of its short circle time and its melting abilities.

Further, we will give you an overview about one Thermoplastic Polymer

- Polyamides (PA)

and three Thermoplastics Elastomers

- Thermoplastic Polyurethan – (TPE-U or short: TPU)

- Polyetherblockamides – (TPE-A or short: PEBA)

- Thermoplastic Rubber Compound (TPR) – (TPE-S = TPS = SBS+PS)

All four are commonly used for injection molding in the footwear industry. And in case it was not mentioned yet. All four are recyclable.

One of the (still raising) stars in the footwear industry, is the material Thermoplastic Polyurethan (TPU). TPU was first discovered in 1937 by Otto Bayer and his coworkers at the labs of I.G. Farben in Leverkusen, Germany. A TPU is a so-called „block copolymer“ consisting of alternating sequences of hard and soft segments. It is formed by a poly-addition reaction between methylen-diphenyl-diisocyanates (MDI), one or more short-chain Diols („chain extenders“) as well as long-chain Diols.

The variation of the ratio, structure and/or molecular weight of the reactants allows chemists to create an enormous variety of TPUs (with some restrictive limitations). Depending on the desired material properties, TPU grades can be produced fine-tuned and customized along a wide range of requirements. Besides its flexibility and durability, TPU has several mechanical benefits over other elastomers: It has an extraordinary tensible strength, a solid load bearing capacity, and an enormous elongation at break.

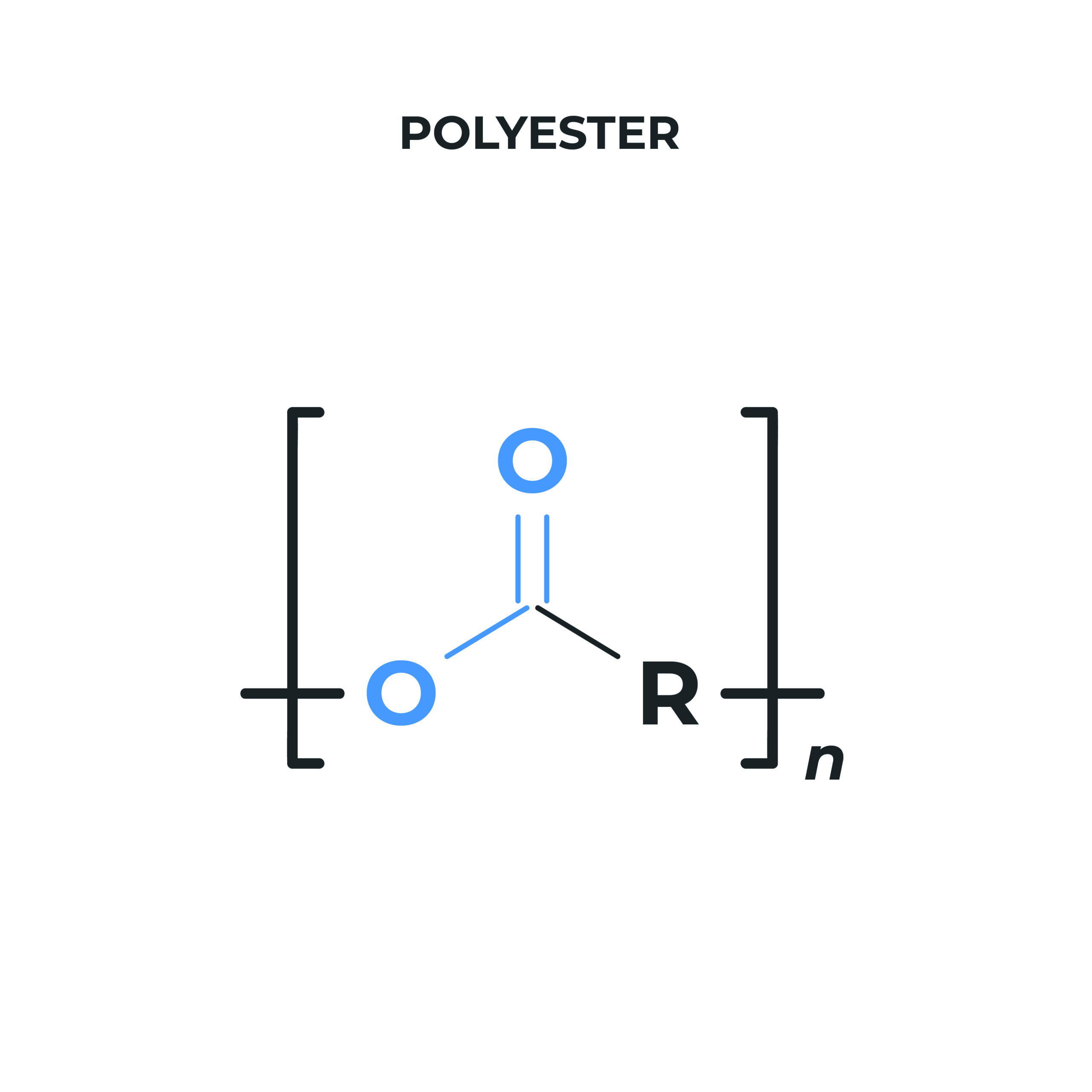

TPU can be classified in three types: Polyester, Polyether, and Caprolactone, whereas only the first and the second type have relevance for footwear industry and will be discussed further.

Polyester

Chemically expressed Polyester is the category of polymers which contains the ester functional group in every repeat unit of their main chain.

As a specific material it mostly occurs as the type of polyethylene terephthalate, which is abbreviated with well know term PET. Polyester exists in both natural and synthetic forms. When it comes to sustainability matters all natural occurring polyesters are of course biodegradable, whereas only a few of the synthetic ones are.

Polyester has three functional benefits which explains its extensive usage in the clothing and footwear industry. First, Polyester has excellent oil and chemical resistance. Secondly, the abrasion resistance is good, and lastly its physical properties are well-balanced.

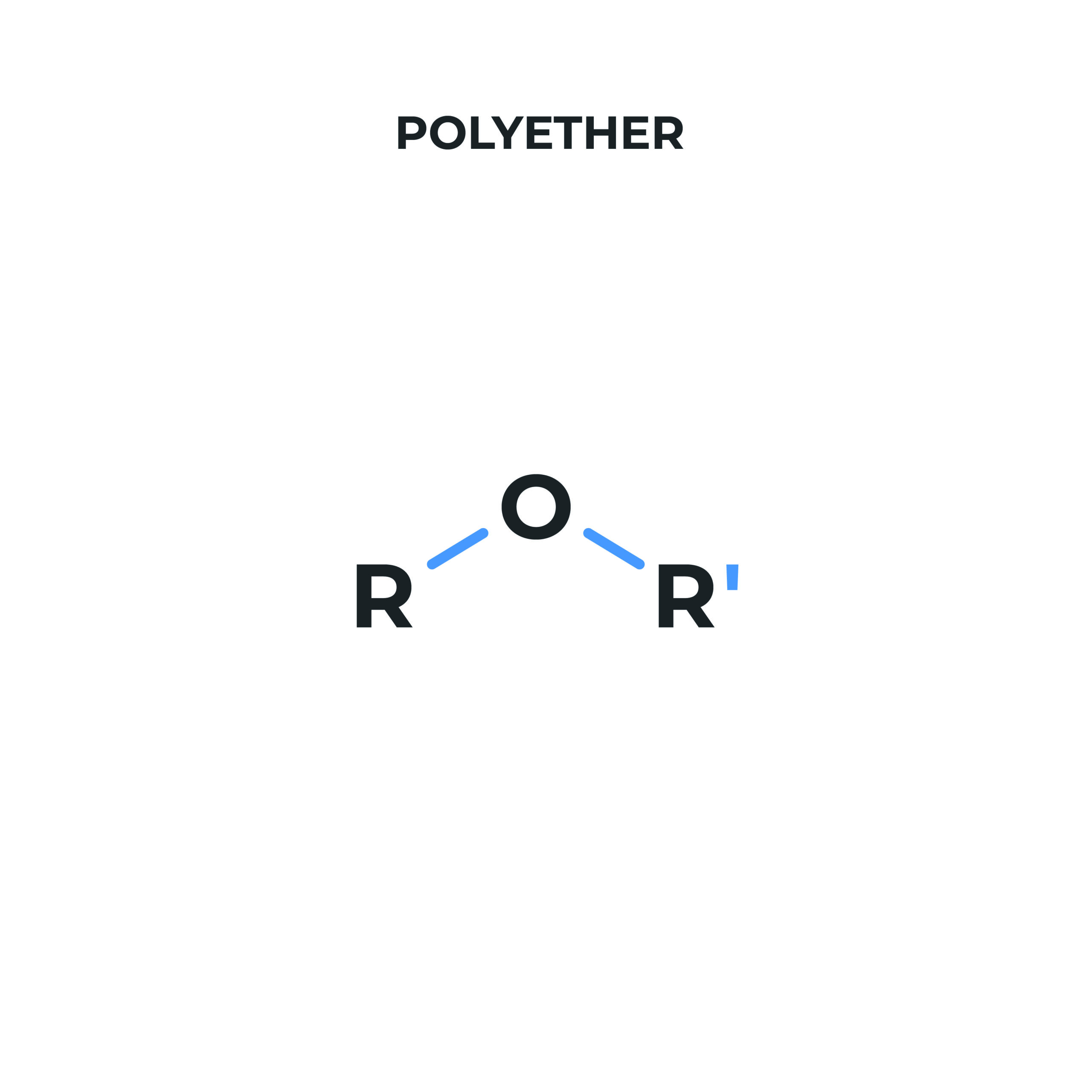

Polyether

Polyether is the polymer category which contains ether linkages in their main chain.

The fact that Polyether TPU has excellent hydrolysis resistance, and that it is durable against microbial attack makes Polyether suitable for applications requiring contact to water. Even better, Ether has superior low temperature flexibility and good abrasion resistance, which qualifies the material for e.g., outdoor winter activities. When it comes to combining Polyether to other plastics in the same application, it is quite helpful that it has good bonding abilities to Polyamide 12 (check section Polyamide below). One disadvantage compared to Polyester is that Polyether is more expensive.

A second way to classify TPUs is the distinction between “aromatic” or “aliphatic”.

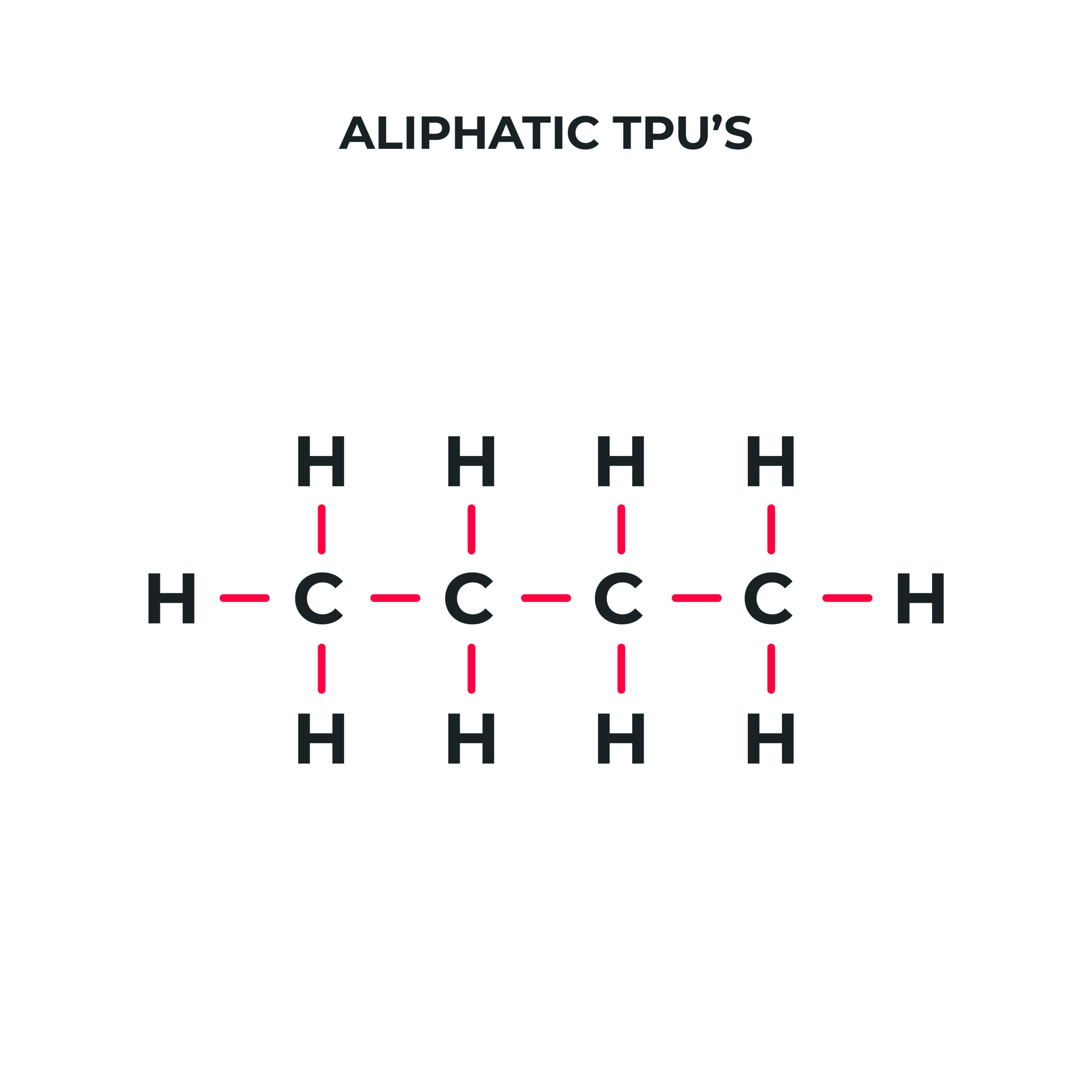

Aliphatic TPU

Aliphatic TPUs are based on isocyanates as H12MDI, HDI or IPDI, are light stable and offer excellent optical clarity. Unfortunately, Aliphatic TPUs are expensive compared to aromatic Polyester and aromatic Polyether which disqualifies them for a vast of footwear applications.

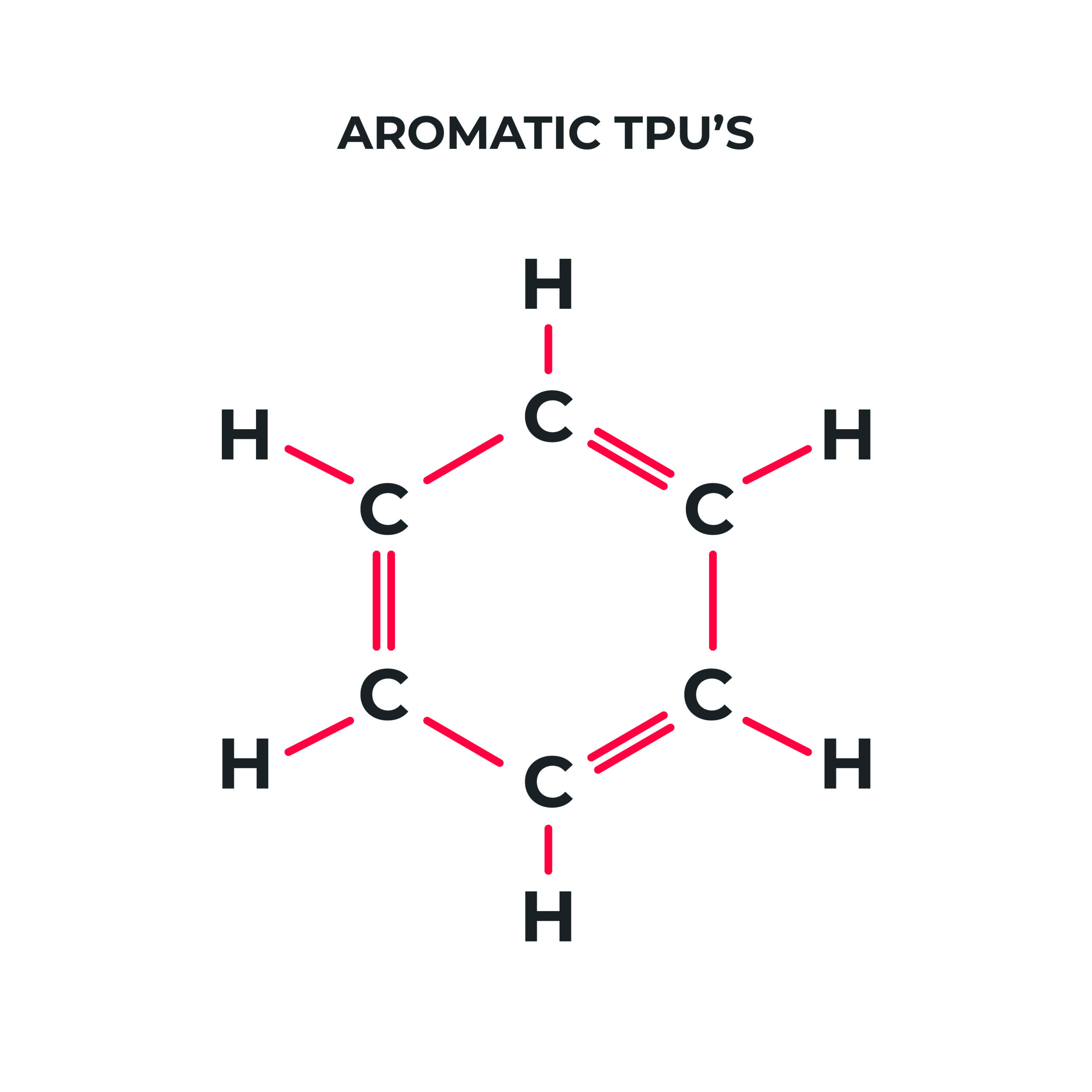

Aromatic TPU

Aromatic TPUs are based on isocyanates as MDI and count as so-called „Workhorse products“, since they can be used in almost all applications which require flexibility, strength, and toughness.

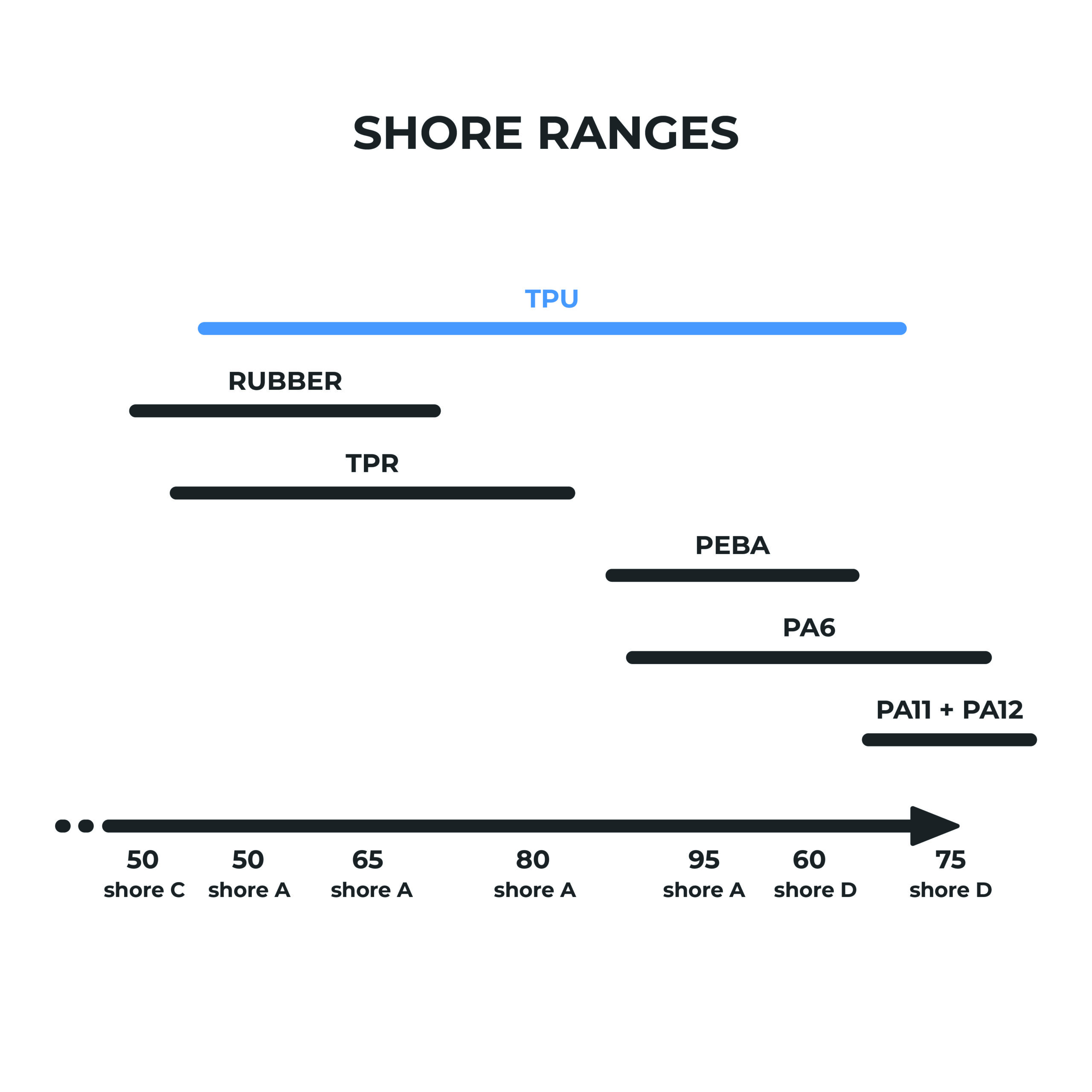

As indicated above, TPU materials can be used for almost all categories of footwear applications. The hardness can be adjusted from very soft (e.g., sneaker outsoles) to very hard (e.g., shank applications). Moreover, TPU is UV resistant and can therefore be used for articles which are exposed to sunlight.

Let’s pick some requirements of footwear components which are perfectly fulfilled by TPU.

Side panels need to be UV resistant, have an appropriate strength to resist the pulling of laces and need to be flexible (shore A) bend along the upper. External heel counters need to be both UV resistant and hard/stiff enough in accordance to protect and support the heel. Shanks need to be tough and stiff (Shore D) and UV resistant.

There are actually great examples of existing shoes on the market, which are totally made of TPU materials and can therefore be fully recycled.

Polyamides (PA) – The stiff ones

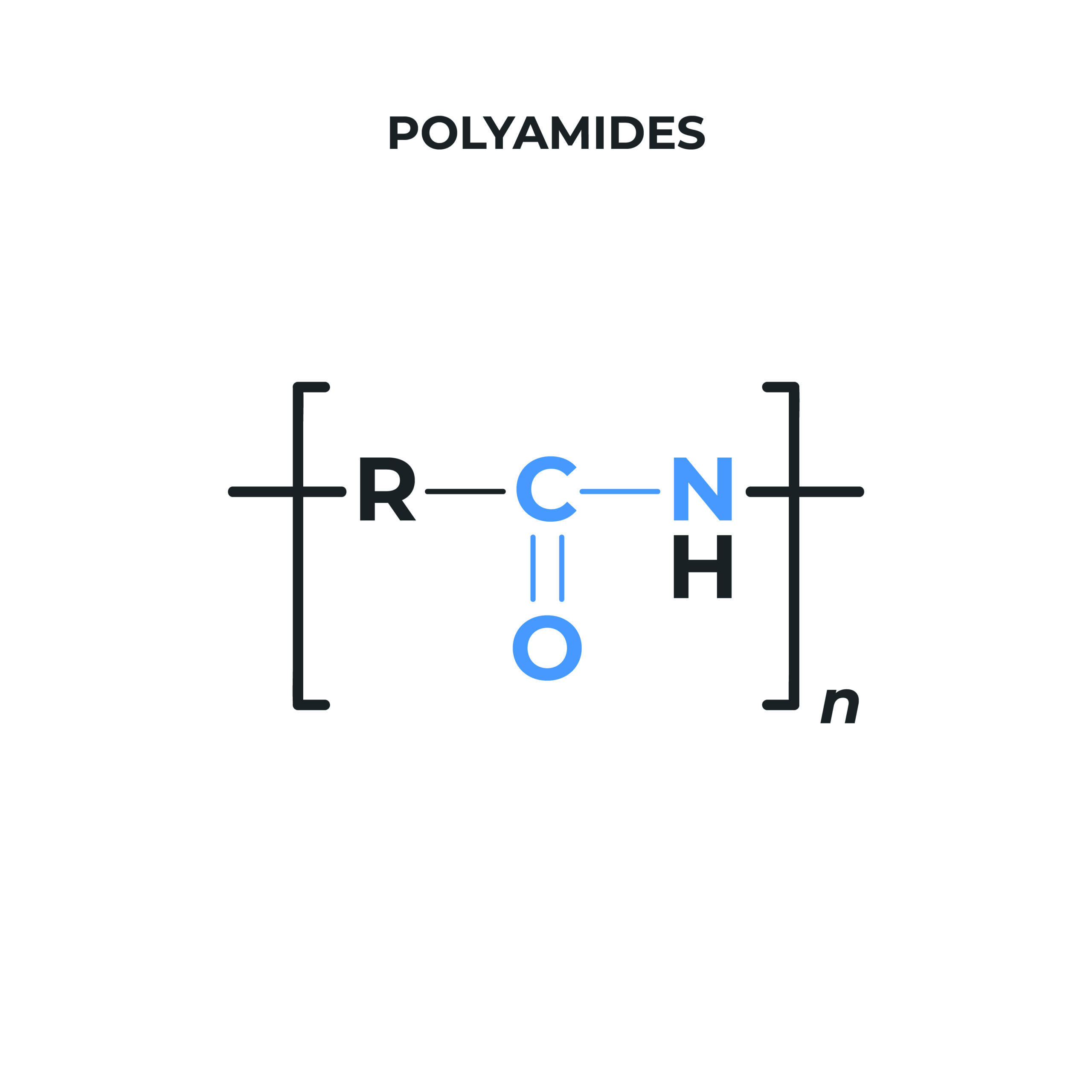

Another classical material of injection molding in the footwear industry are Polyamides (PA). Chemically speaking, Polyamides are long-chained molecules in which the repeating units in the molecular chain are linked together by amide groups. Amide groups (CO-NH) are commonly formed by a poly-condensation reaction between a carboxyl group (COOH) and an amine group (NH2).

PAs occur both naturally (e.g., proteins, such as wool and silk) and synthetically. The footwear industry uses synthetical PA, such as well-known Nylon.

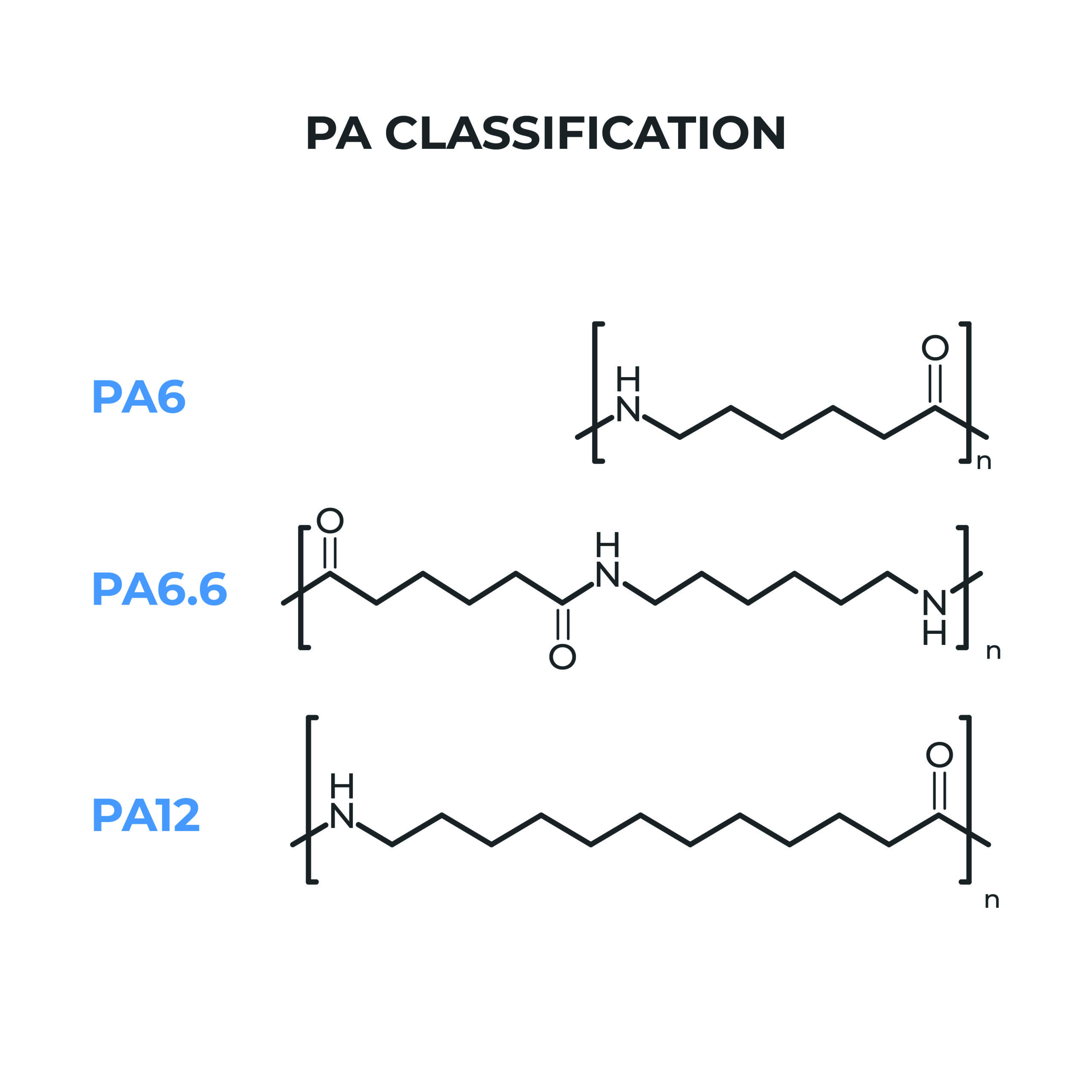

PAs commercially exist in different Polyamide types, such as PA6, PA6.6, PA4.6, PA6.10, PA11, PA12. Depending on the number of carbon atoms in between the amide groups physical properties such as density or liquid absorption vary on a wide scale.

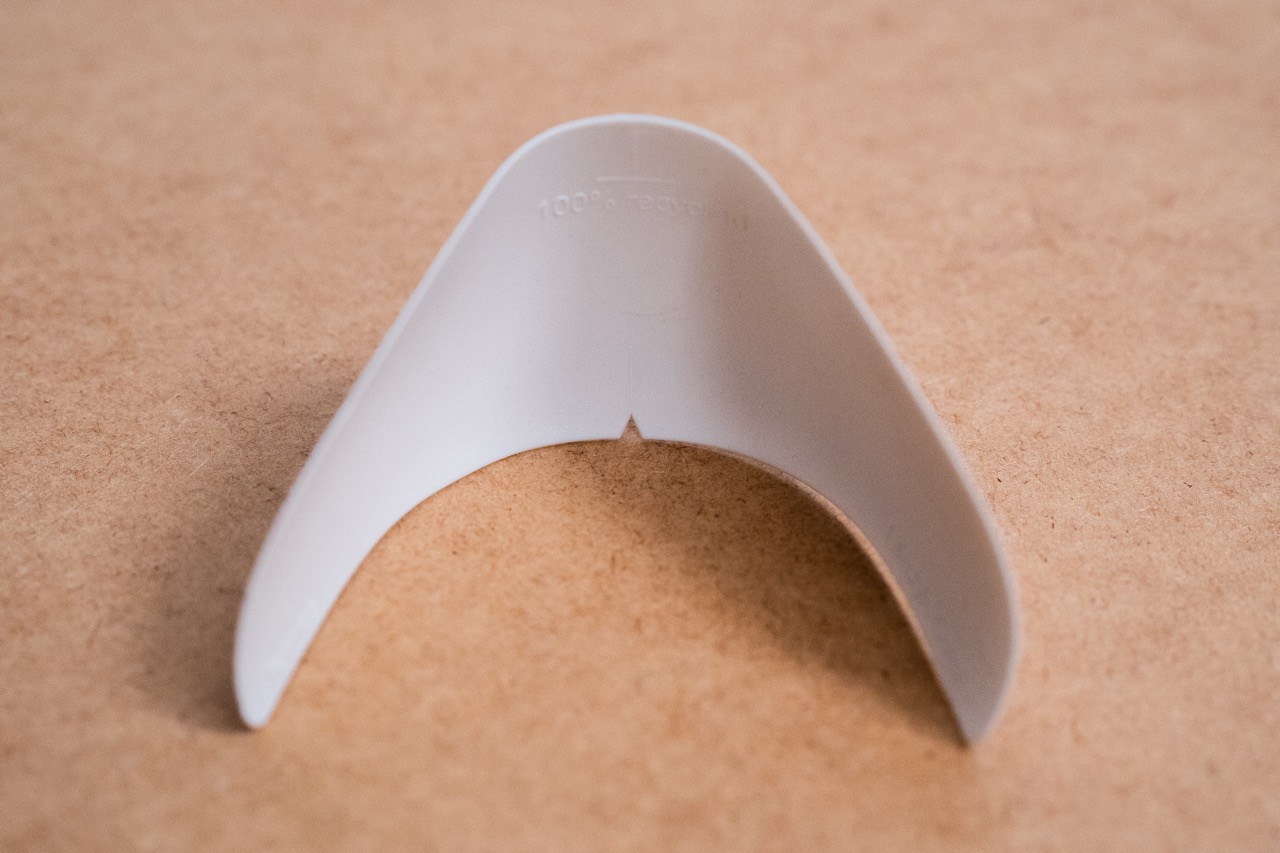

Compared to TPUs Polyamides are considerable stiffer. Therefore, they are mainly used for applications where a certain reinforcement is required, e.g., a Shank system, Strobel insole board, eyelets.

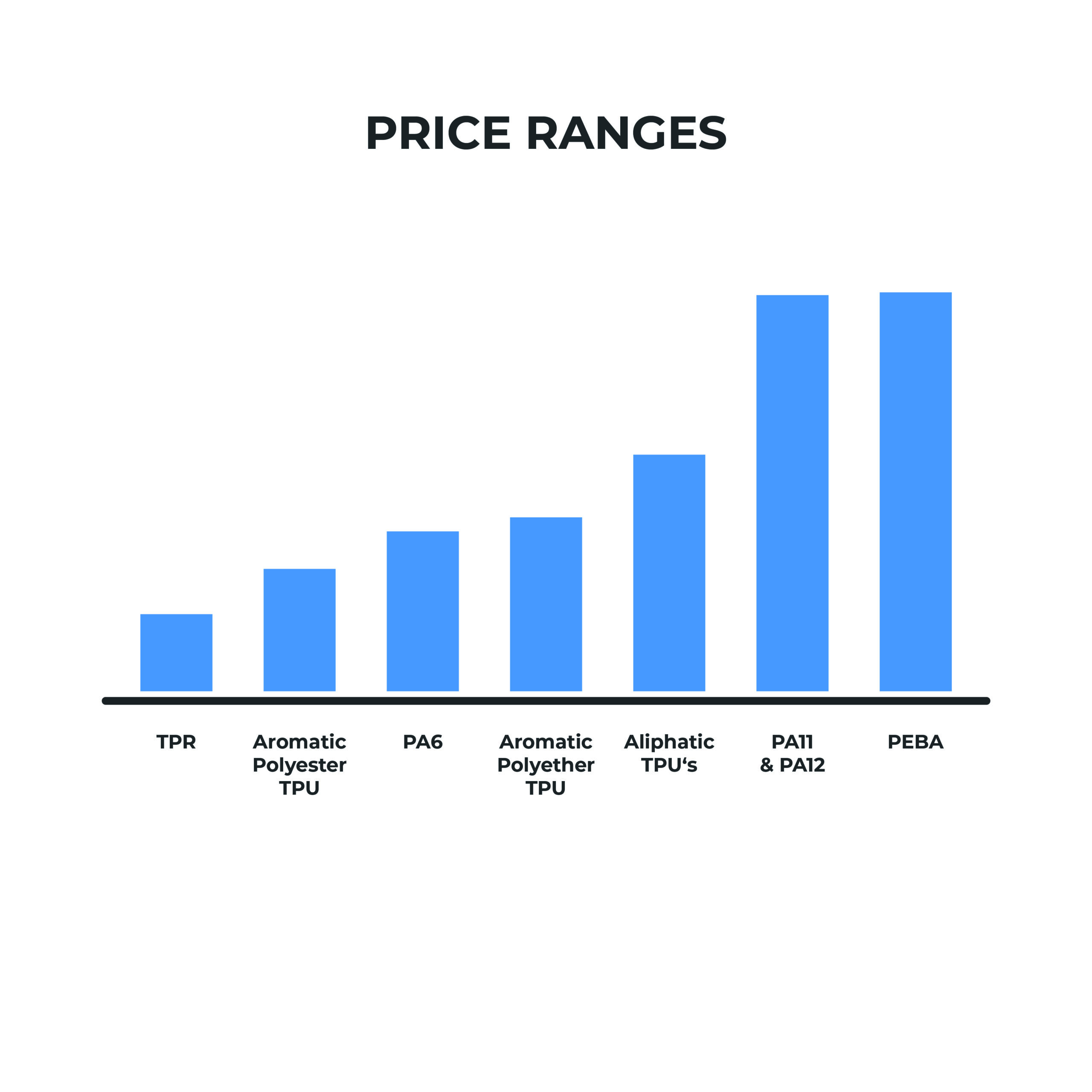

But PA has its limitations. In comparison to PA11 and PA12 especially PA4.6, PA6, PA6.6, PA6.10 absorb more water & humidity. Moreover, low temperature harms the flexibility of PA, which disqualifies PA for outdoor activities. Compared to TPU, the price of PA is relatively high. You can tell as a rule that the longer the PA chain, the more expensive the PA becomes. A PA12, for instance, has almost double the price of a PA6.

Due to the stated limitations and except for a few PA6 grades, mainly PA11 and PA12 grades have been successfully established in the footwear industry, usually in high performance applications.

A PA12 soccer outsole needs to be light weight, reinforced, UV resistant and flexible even under low temperatures. A PA12 soccer outsole in connection to TPU ether studs works perfectly, because of the bonding ability of PA with TPU (TPU has a better traction behaviour and is more comfortable to walk on).

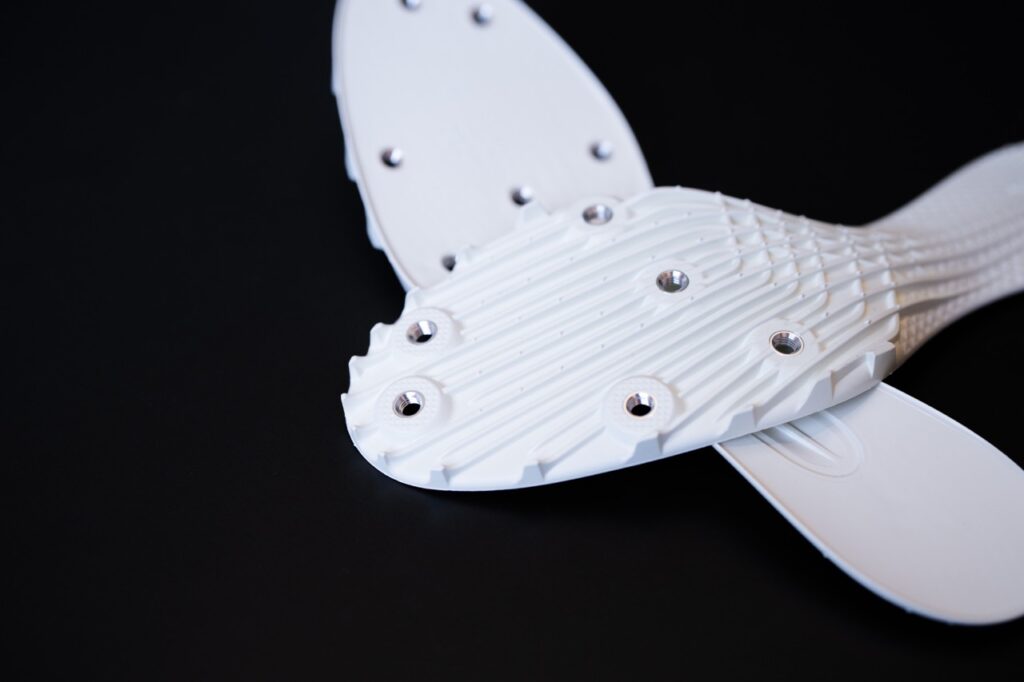

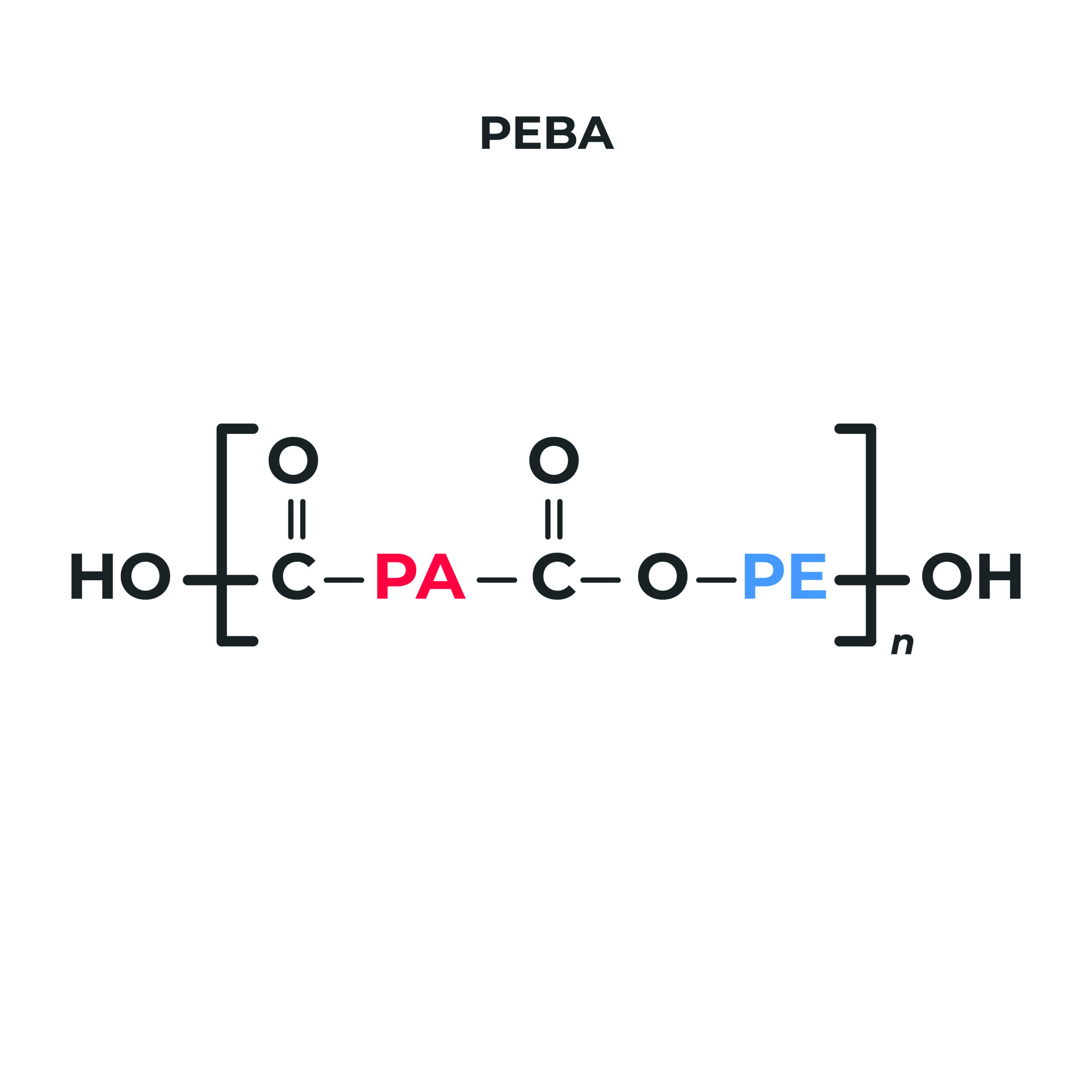

Polyether Block Amide (PEBA) – The luxury one

Polyether Block Amide (PEBA) count as the luxury, high performer under the materials for the footwear industry.

What is PEBA, chemically speaking? PEBA materials are block copolymers made up of rigid polyamide blocks and soft polyether blocks. By manipulating these blocks and their relative ratio a large property spectrum from very hard and rigid to very soft and flexible can be achieved.

PEBA grades combine the benefitting properties of Polyamides (e.g., toughness, low density) with the high flexibility/elasticity of Polyether’s:

- Low temperature flexibility and impact resistance (at temperatures lower than -40 °C)

- Relatively low density (1.01 g/cm3) compared to TPUs (1.19g/cm3)

- Proper energy return

- Fatigue resistance

- Good chemical resistance

- the lightest of all thermoplastics

Similar to TPU, the hardness of PEBA can be adjusted from very soft (e.g., external heel counters) to very hard (e.g., insole boards, sprint plates, or outsoles). The option of usage are almost endless. Especially in the sport footwear industry PEBA grades are well established, but due to their relatively high price (approximately as expensive as PA12) they are mainly used for high-performance applications. The above stated superior properties PEBAs are predestined for winter sports (e.g., ski and snowboard boots) and other competitive sports where low weight, weather resistance, energy return, and fatigue resistance are required (e.g, ultra trail running).

And as if all these positive skills of PEBA are not enough: Designed and applied in an clever way, PEBA is also sustainable! There are actually great examples of existing footwear on the market, which are totally made of PEBA materials and can therefore be fully recycled.

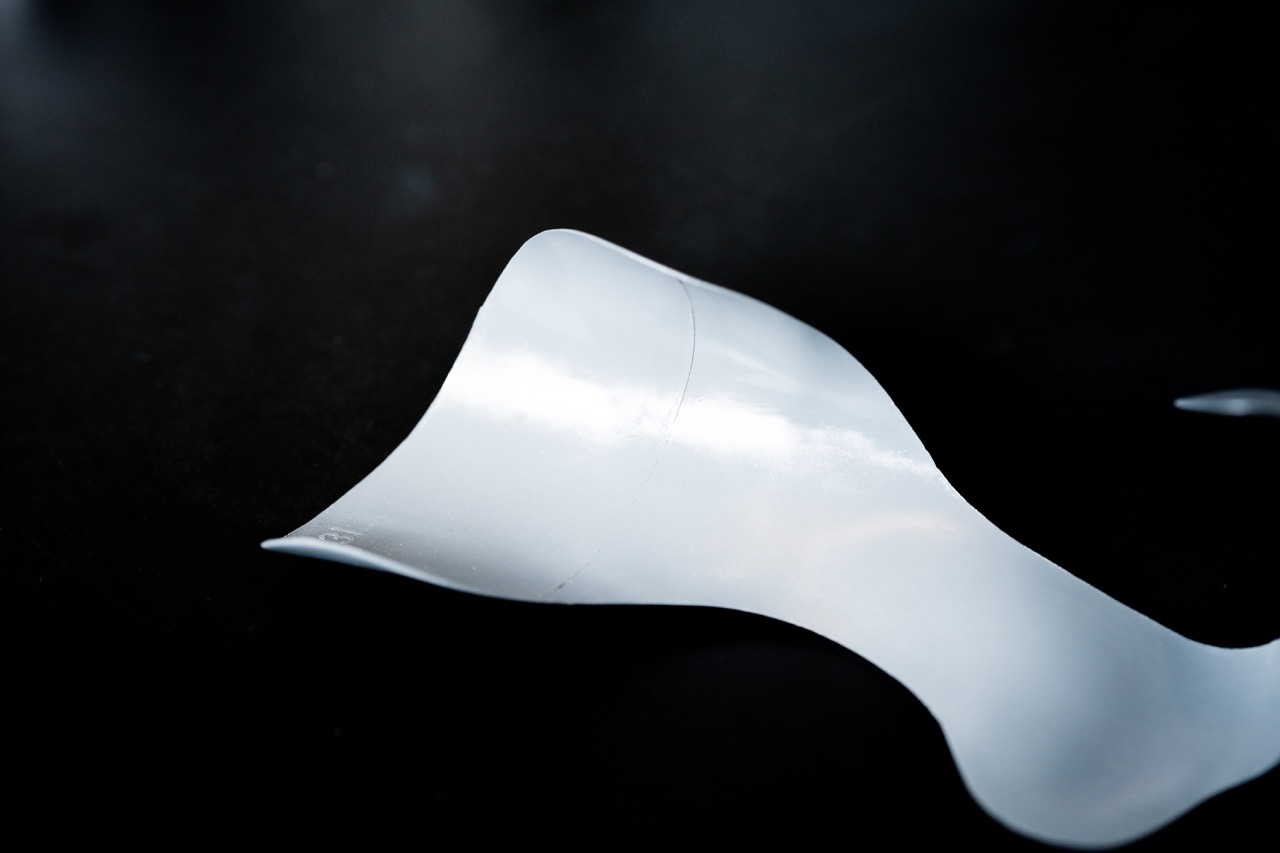

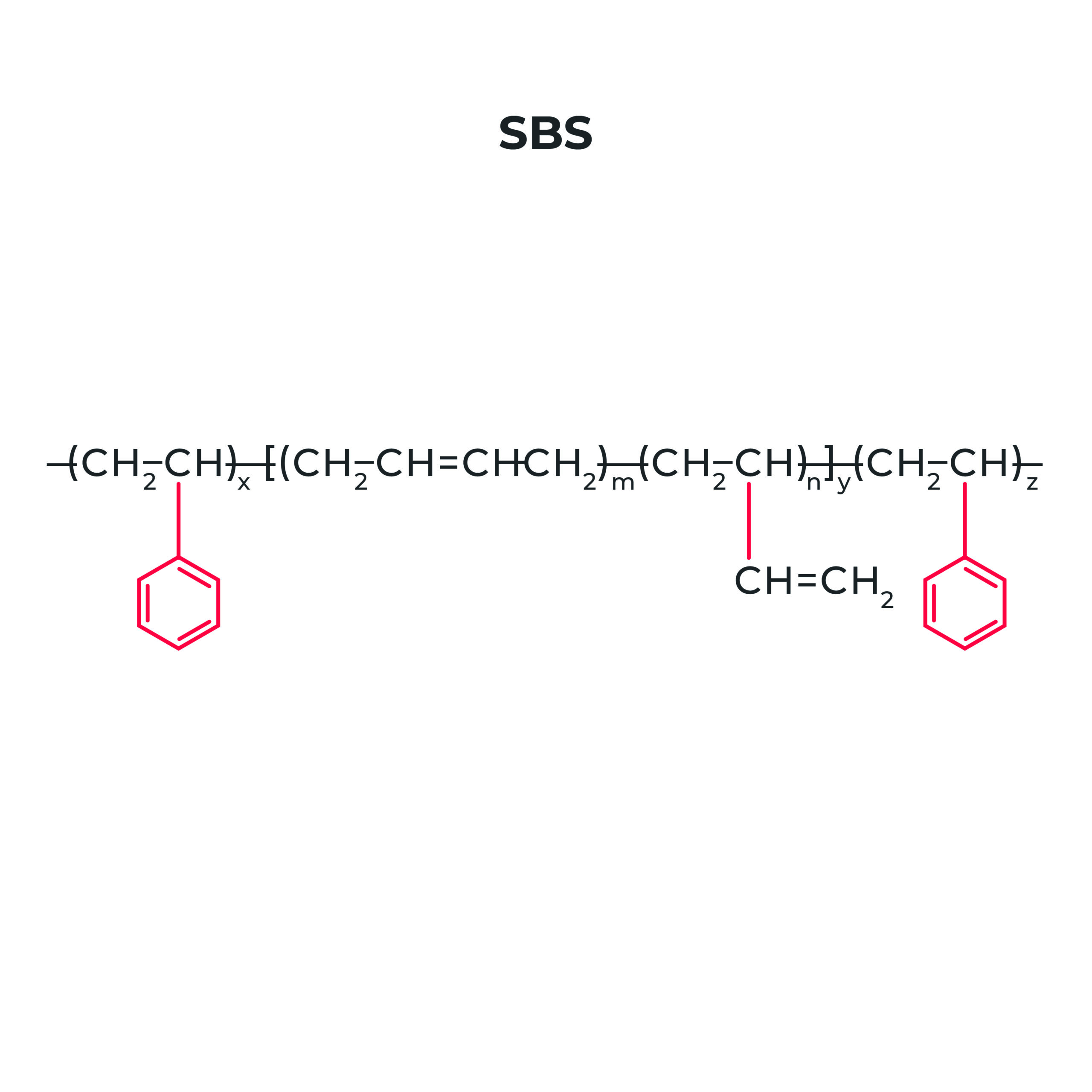

Styrene-Butadiene-Styrene (TPS-SBS) – The biggest group

The most occurring thermoplastic elastomer (TPE) is the styrene based thermoplastic styrene elastomer (TPS).

The easiest, best performing, and cheapest TPS is a mix of styrene and butadiene, Styrene-butadiene-styrene (SBS). As illustrated above, the butadiene is the elastomeric (soft) linking segment between the polystyrene blocks. Due to its synthetic nature, SBS is logically not biodegradable. In its not hydrated form, it is almost only used to modify other materials. Common applications are in the area of street construction and baby diapers. SBS can also be used in the footwear industry. However, due to its poor UV resistance it is more suitable for footwear components which are protected from the sun (e.g., heel counters).

SBS is rarely used in an unmixed form because it has an amorphous structure and therefore melts very slowly when exposed to heat. To improve its properties, it is often mixed with thermoplastics. For recycling, and the injection molding process of heel counters, pure (Nonylphenol free) SBS is necessary.

The only element to be added, which improves the properties of SBS without harming the ability of thermo-recycling, is Polystyrene. Polystyrene, as mentioned above, makes SBS stiffer and is already an element of SBS.

Polystyrene (PS) is a synthetic polymer made from monomers of the aromatic hydrocarbon styrene. It occurs solid or foam and is not biodegradable, cannot be decomposed by bacterias. Conventional polystyrene is clear, hard, and brittle. It was first discovered in 1839 by the apothecary Eduard Simon in Berlin. PS is a very cost-efficient material. It is also one of the most widely used plastics. PS can be the material for protective packaging, containers, lids, bottles, trays, tumblers, or disposable cutlery.

In the footwear industry High Impact Polystyrene (HIPS) is used, which is less brittle and impact resistant even at low temperatures. High availability and low prices on the secondary market make PS suitable for recycled components e.g. our heel counters, even though the properties limit the application.

To sum up, an overview of the prices of all materials we introduced in this post and their hardness range.

If you liked this article, make sure to follow our Social Media channels. You can contact us anytime via LinkedIn, Instagram & Facebook. We are happy to receive any feedback and tell us what other topics are of interest to you. We will try to address them in the near future.

Thanks for checking out our blog!

Neueste Kommentare