FORMING THE FUTURE

We, as the innovation.framas teams, want to create new unprecedented products while also improving upon existing ones. Therefore, we work proactively in the areas of product development, sustainability, digitalization, and rapid prototyping.

product development

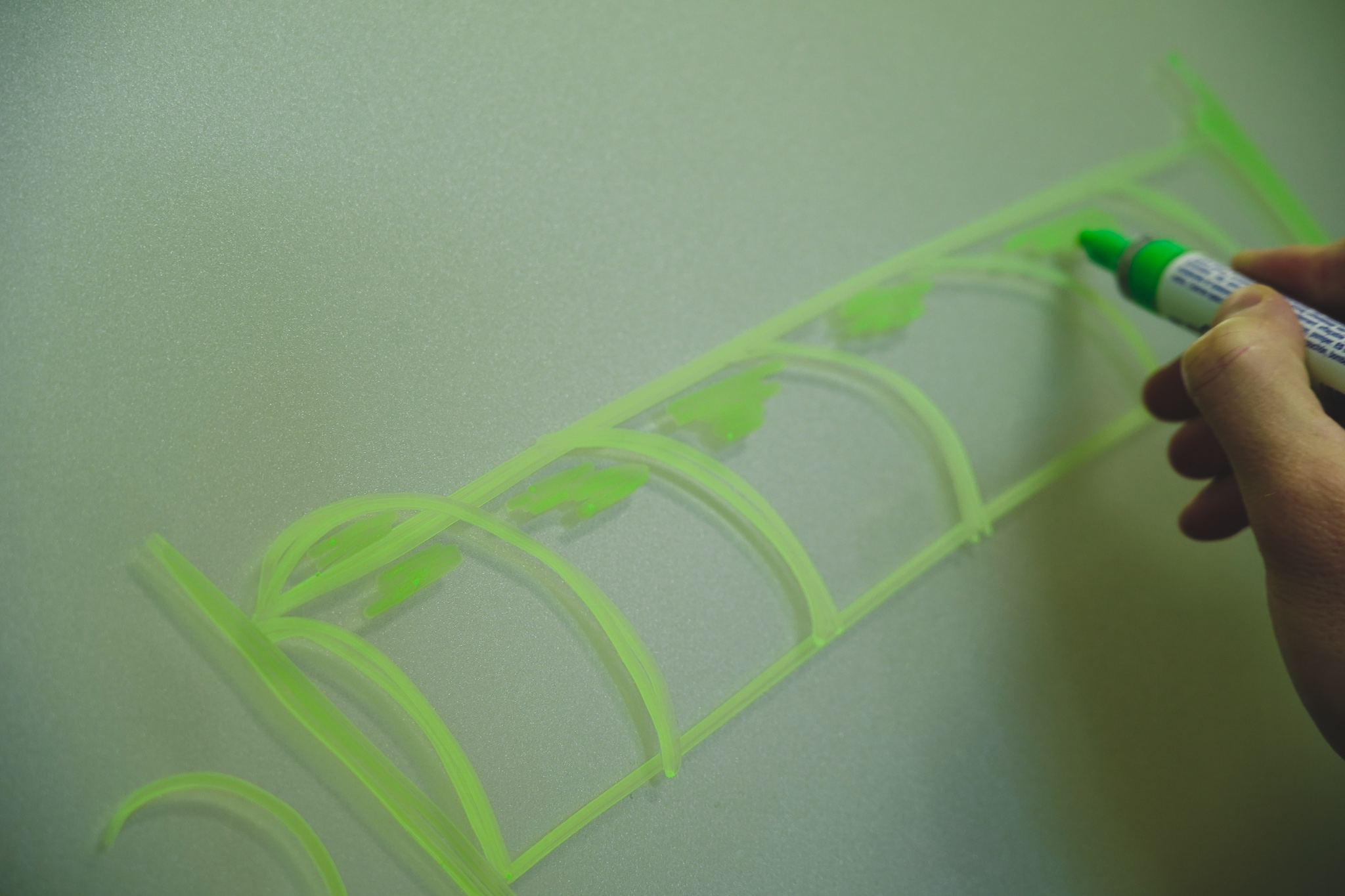

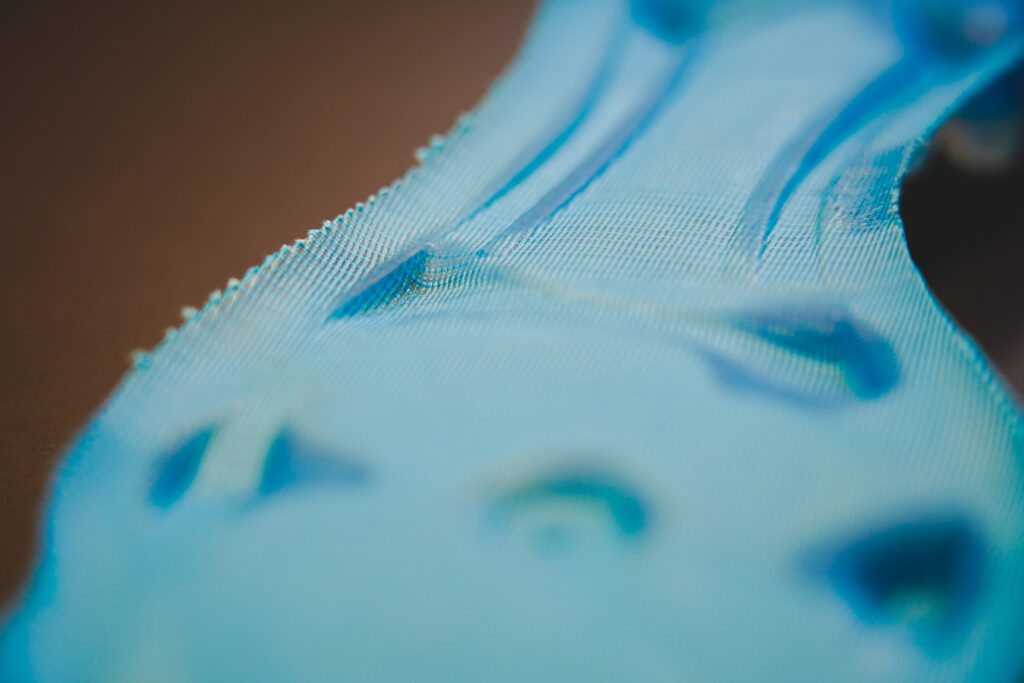

New innovative products have a high priority to remain competitive on the market. Mainly it is about single components and product concepts. We accompany our customers from the first design idea over prototypes up to the production stage.

In doing so, we offer the following services:

Component development + concept development

Development of newly functions

Process development during product development

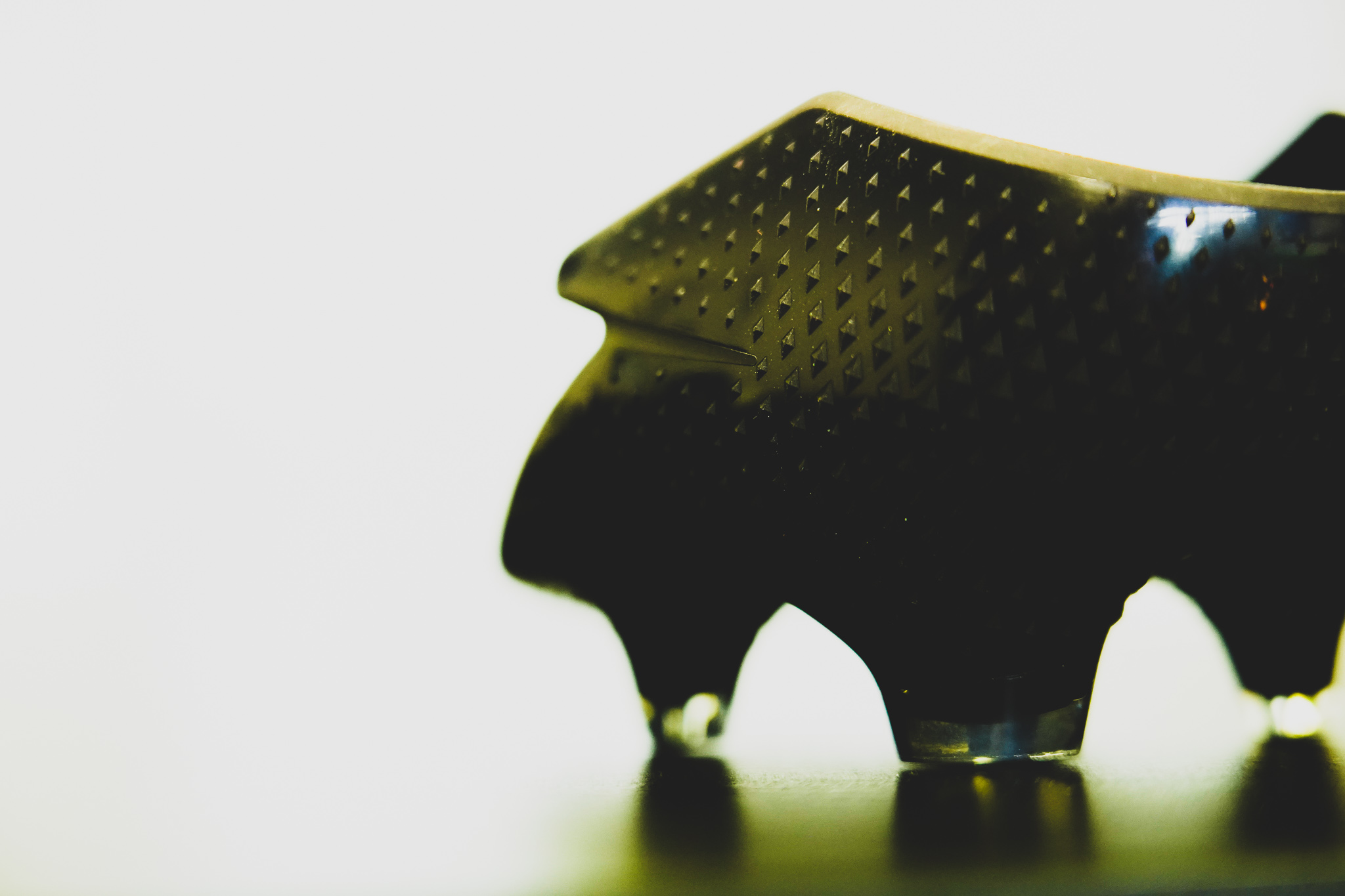

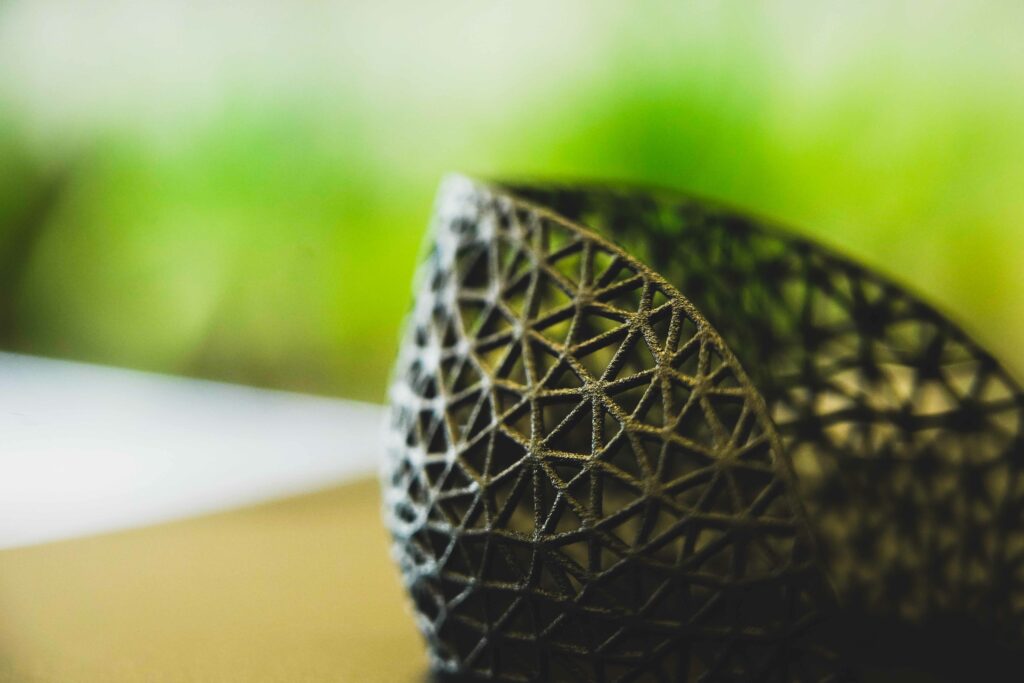

Product development in the 3D printing area and the production of prototypes

Integration of state-of-the-art technologies into your products (Internet of Things, AR / VR)

Workshops for the joint conception of new products

Research & consulting in the field of materials and sustainability

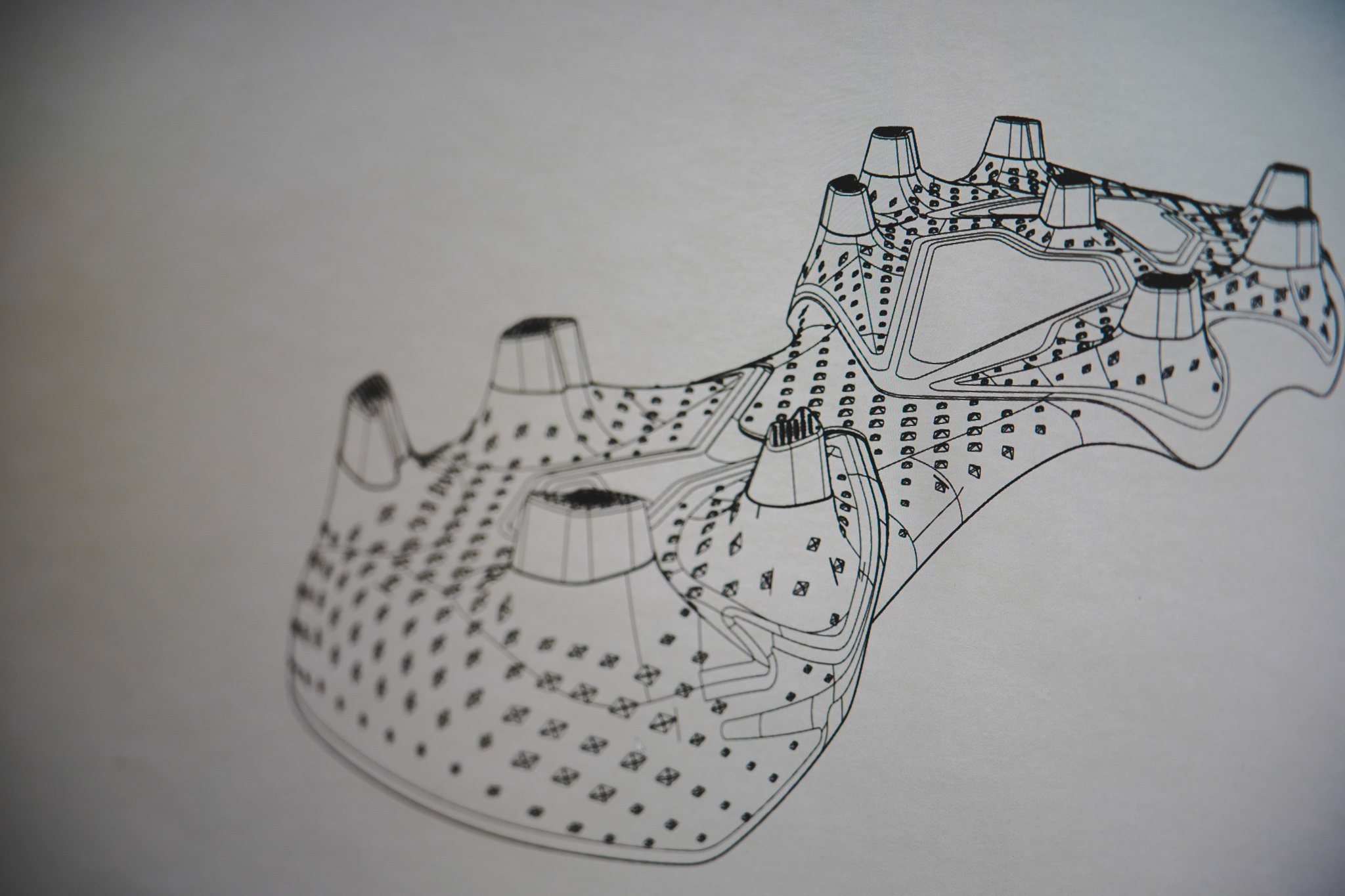

3D Product Creation

+ Simulation

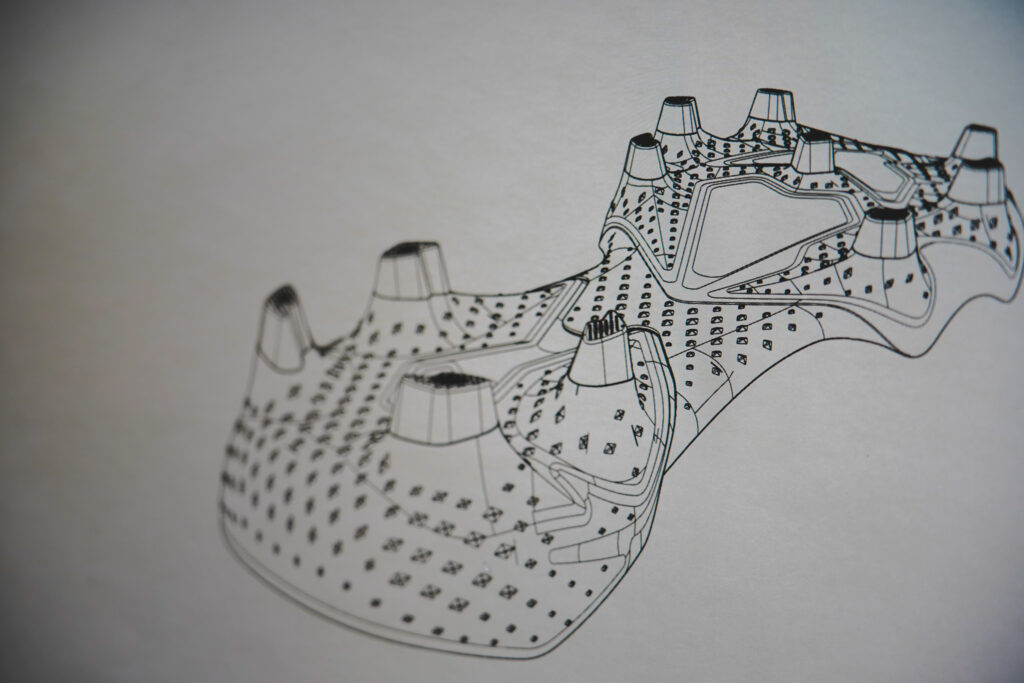

With our broad expertise in design, simulation and 3D design, we can help you create 3D models. We create new designs, structures, or new functions for you and can test these in durability, functional behavior and strength using the appropriate simulation tools. If new processes are required for certain products, we also evaluate and implement them.

Among others, we work with software from Rhinoceros, Grasshopper, Siemens NX, FEA Tools, nTopology, Materialise Magics, and many more.

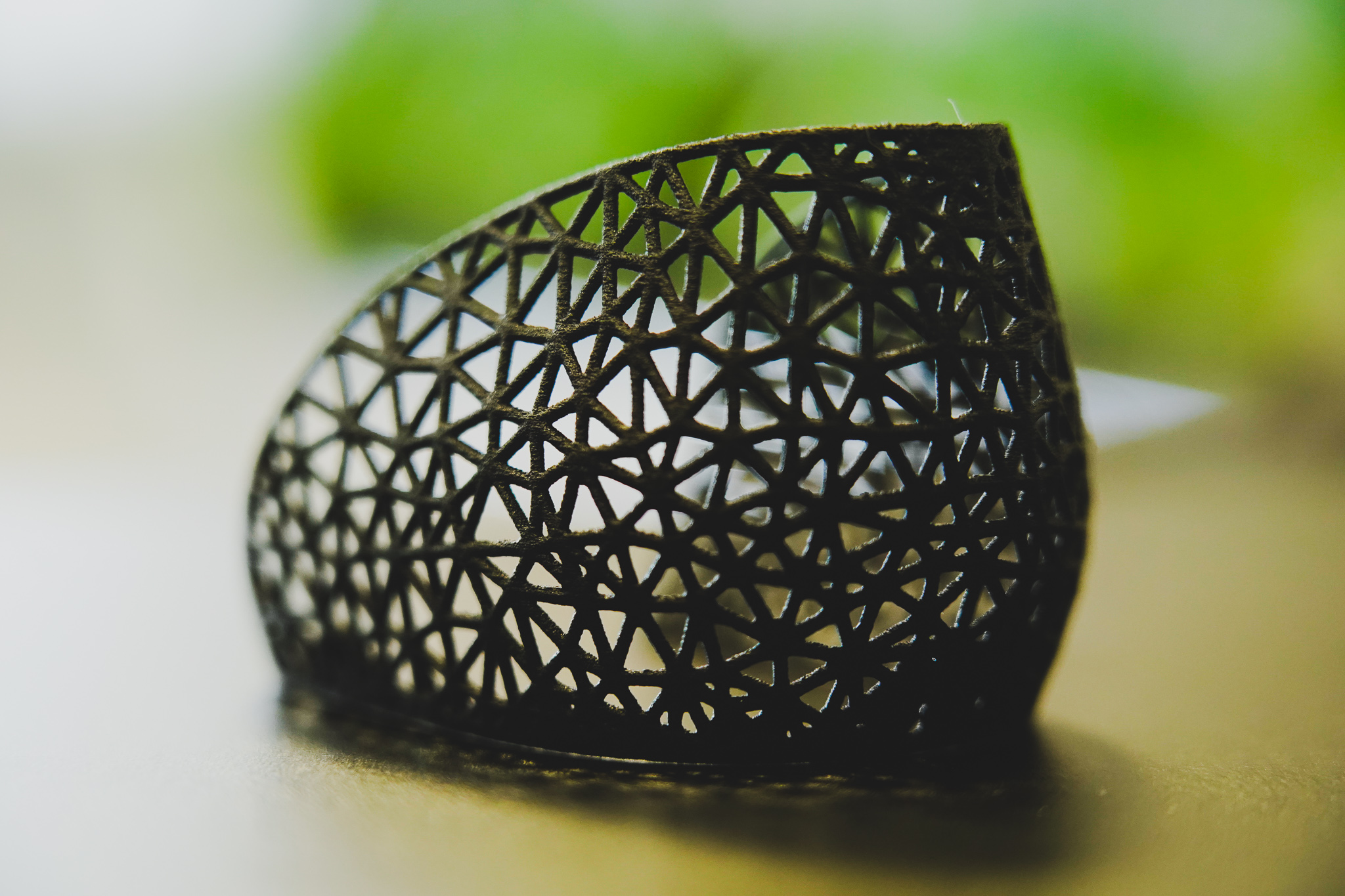

3D Printing

Innovation drives us.

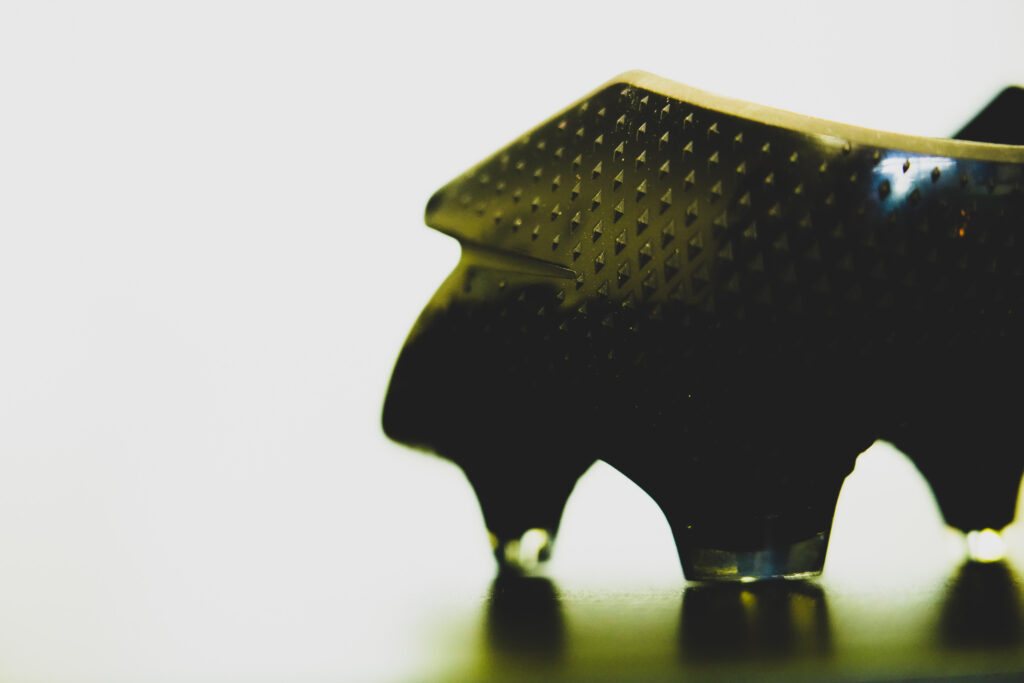

With the SLS, DLP and FDM printing systems we use in the framas group, we can process powder, resin and filaments into functional and dimensionally accurate prototypes. These can be printed for simple illustration purposes as well as for functional testing purposes.

With our framas in-house 3D print space, we can produce rapid 3D prints from a single source. Already during the product development process, it is possible to print prototypes within shortest time to give you the possibility to evaluate and test your product at an early stage.

For us, not only material research in injection molding is relevant, but also the research of different materials used in 3D printing and their properties.

Our SLS system offers the possibility to manufacture in small batches. This builds the bridge to be able to manufacture the first products before our moldshop comes into play.

Digitalization

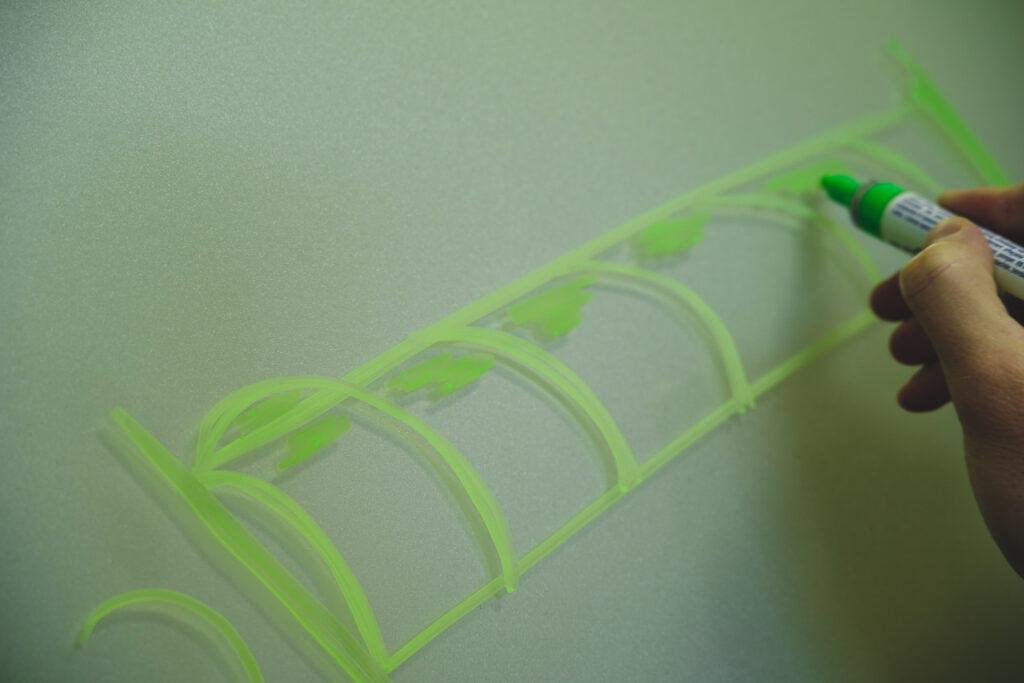

With the implementation of new types of software and tools, we continue to drive digitalization forward.

The latest technologies and machines are not only to be found in our production facilities. Already in product development and research we use the latest technologies and integrate them in our products. As well revolutionary tools like

(VR · Oculus Quest / AR · MS Hololens) are in use to be able to work globally and location-independent.

Collaboration

We actively promote cooperation with start-up companies in order to provide a platform for new ways of thinking and to turn innovative product ideas into reality.

By networking beyond the plastics processing industry, we create new perspectives. Sustainability in our products is our top priority.