We form ideas

In our moldshop, high-performance plastic injection molding tools are created for your products. Our many years of experience enable us to keep up with the innovative designs of the industry while maintaining high quality standards. The moldshop.framas teams are integrated into the product development process from the beginning and work in close exchange with the development and production departments.

Services

The networking of our worldwide moldshops and production centers allows you to save costs and time and ensures a fast response from our side.

With the most modern machines in all plants, we can guarantee framas’ quality across all locations.

In order to produce the optimal plastic injection mold for you, we design your product as a 3D model. We use the most modern CAD software, like Rhinoceros® and Solidworks for the production-ready tool design. Possible sources of error of the tools are identified well in advance with our injection molding simulation software from Autodesk Moldflow®.

With rapid prototyping, you can see, test, and improve your product in real time.

TECHNOLOGY

Perfection in every component

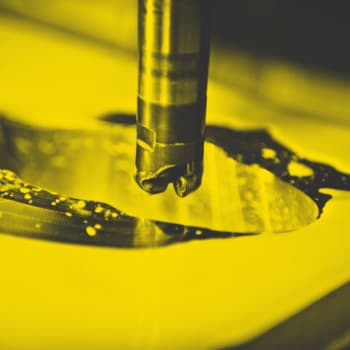

In our air-conditioned moldshop centers we work with state-of-the-art technologies and various steel qualities and hardnesses. This guarantees accuracy of the tools produced and adapts them to the requirements of the injection molded components.

END-TO-END-PRODUCTION – the entire process at one location

WELL-FOUNDED KNOW-HOW in various tool techniques

RAPID PROTOTYPING

PRODUCTION-ORIENTED 3D-DESIGN

ERROR DETECTION through simulation

AIR-CONDITIONED ROOMS guarantee accuracy of the tools

VARIOUS STEEL QUALITIES AND HARDNESSES in use

LASER-TEXTURE – different surface haptics and functional features

Machinery

The framas moldshop centers are equipped with the most modern and innovative 3-axis and 5-axis milling machines, which guarantee high precision of milled parts and gives you an edge over your competition.

Our laser structuring machines create functional elements and surface haptics that can be directly reproduced in the plastic injection molding tool and thus integrated into your product.

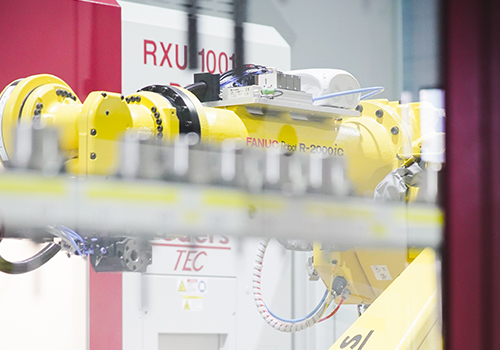

At our location framas Korea Vina we have implemented an automation pilot project, which enables continuous production.

Six Roeders© milling machines combined with a 6-axis Fanuc® robot create new possibilities which will be implemented at other framas locations in the future.

Sustainability

We also place great value on sustainability in our moldshop centers.

Automation processes make production increasingly efficient, faster, and save energy. Laser structure technology also reduces the use of environmentally harmful chemicals present in the traditional etching process.