Room for evolving

development.framas is the link between customers and production. We are your contact for the implementation of your ideas in the area of plastic injection molding.

We accompany and advise you at every single step of the development and production process. We consider which material composition and which structure guarantees optimal performance of your product while working closely with our in-house laboratories, moldshops, production centers and innovation departments.

Services

We coordinate the entire process, which takes place at one location due to our integrated moldshops and production centers. This way we can always keep you informed about the current status of your project and also provide you with an exact calculation of the costs and required time.

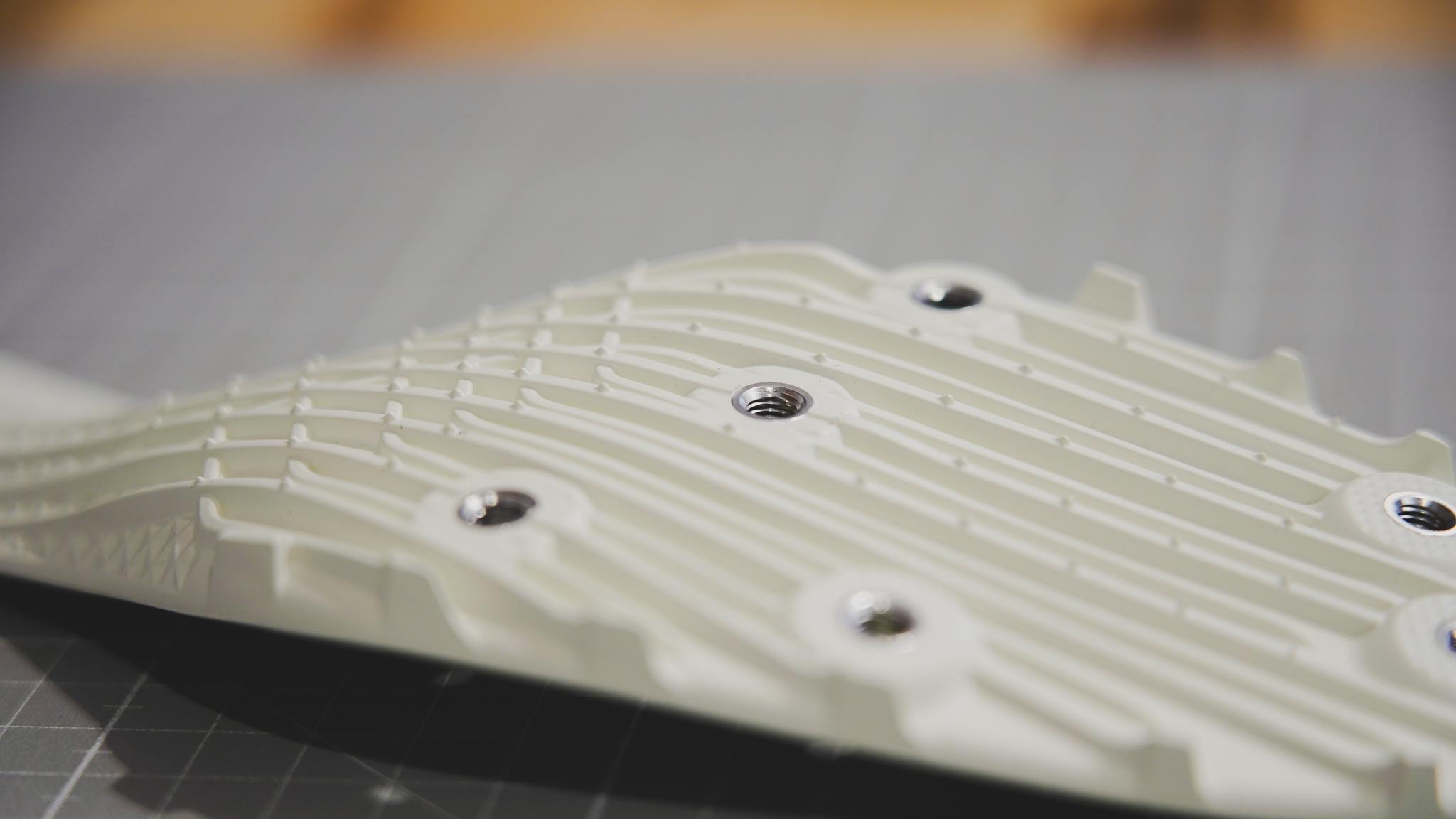

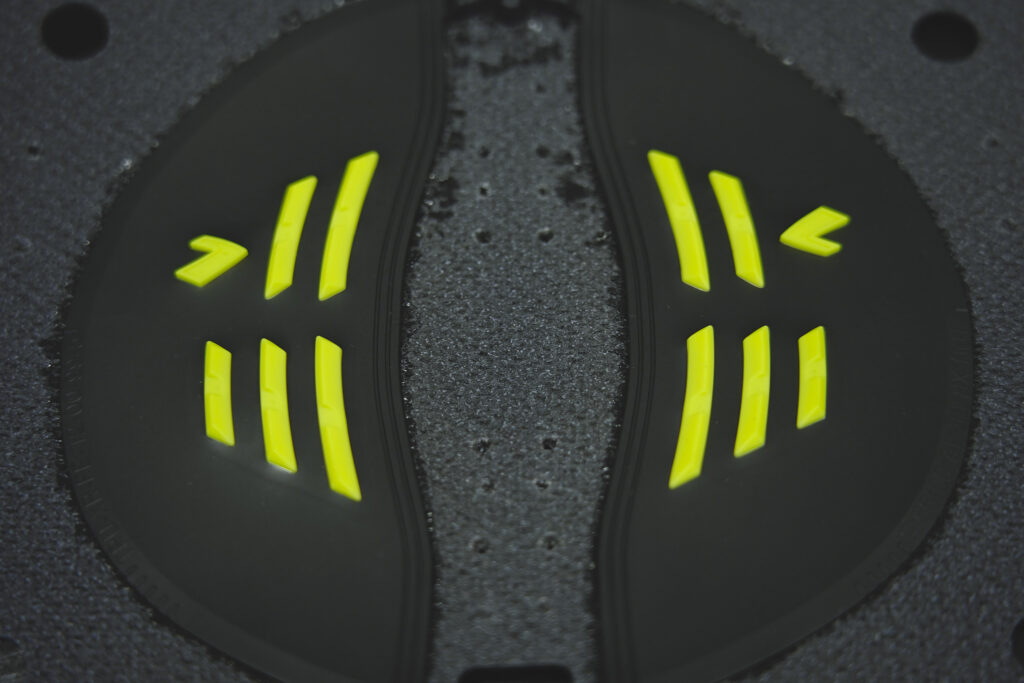

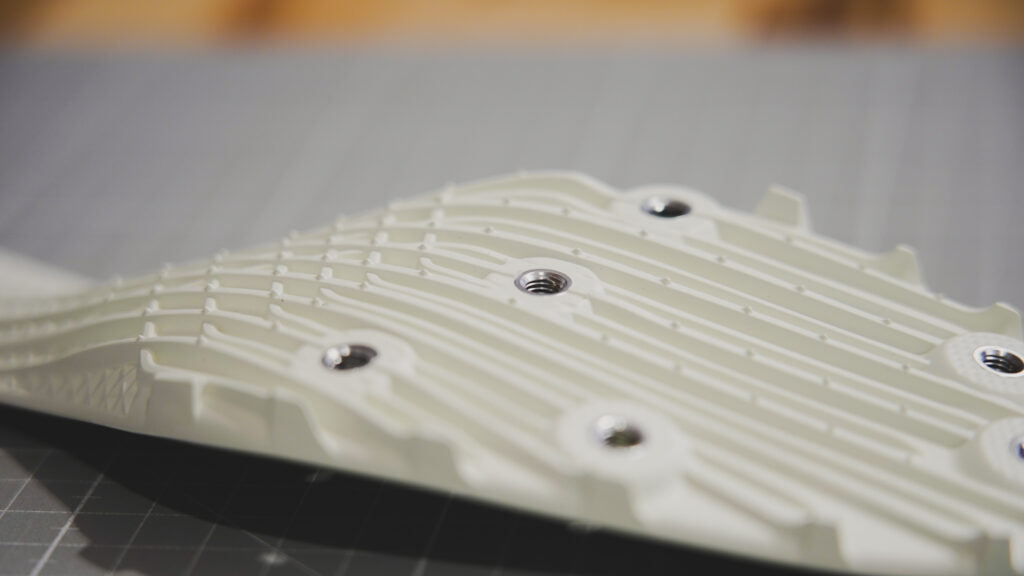

In order to optimize your product for our machines and production, a prototype tool of your product is additionally manufactured in our tool making centers using the rapid prototyping method. This allows you to test your product extensively and make modifications in design or functionality prior to serial production.

PRODUCT DEVELOPMENT

PRODUCTS OF HIGHEST QUALITY

We accompany you throughout all phases of product development, helping to design your product according to the process and guiding it through to serial production. Multi-stage product development begins with the research phase, concept development, and the subsequent feasibility analysis (proof of concept).

We support you in this process with, among other things, extensive materials consulting based on internally conducted tests, trial series, and our many years of experience.

QUALITY

For our products we only use materials which are of the highest quality and functionality. We know that only with the perfect material, can we extract the utmost functionality of the final product. In order to guarantee the best quality, we operate with some of the most recognized plastic suppliers.

We examine the produced prototypes and test them in our lab.framas departments for their mechanical, optical and thermal properties before they are used in production. Additionally, we have the possibility to test different materials and their properties during the sampling of the prototype tools.

Materials

We actively search for new material combinations and have successfully developed five sustainable plastic compositions that have set new standards.

framaprene is a heelcounter material in three versions, all of which contain at least 50% recycled material.

framapur is our own sustainable plastic material, which consists of 100% recycled plastic.

framamid, framafine, and framapex are further material combinations we offer, which are mostly made of recycled material and have different plastic base compounds.

The close cooperation with our innovation departments and the in-house material research teams gives us the opportunity to present innovative ideas and concepts while also offering you our comprehensive expertise.

SUSTAINABILITY

As a plastic processing company, it is important to us to act sustainably and contribute to environmental preservation. Together with partners from the material manufacturing industry, we are looking for possibilities to drive new material compositions even further.

Research in sustainable and biodegradable substances as well as materials with bio-content is of great concern to us. In addition, we actively seek how to reprocess, reuse, and recreate a completely new product from internally (and externally) generated production waste.

We help to provide a mean for all parties to think sustainably.

Contact to the Development Team

MAIL