Transparency and Traceability in Footwear and Fashion Supply Chains

25.04.2023 · Expert Clara Soltau / Editor Luisa-Maria MrcelaIn today’s footwear- and fashion industry, product development professionals are familiar with the challenges of efficiently managing samples along the supply chain. There is often a lack of detailed information about the exact material sources and actual data about the sample status. Due to inefficient manual processes and chaotic data management, time and effort are wasted in searching and waiting for samples. Communication gaps with suppliers can also lead to misunderstandings, resulting in unpleasant delays in the sampling process. The root cause of this problem is often a lack of process transparency. Fortunately, modern tools of digital transformation can help to address this issue by leveraging supply chain transparency and traceability.

However, discussions about transparency developments in footwear and apparel supply chains often result in confusion about distinguishing between the terms of transparency and traceability. This article aims to provide a clear definition of both terms and present practical examples and benefits of their application in the footwear industry

To begin with, the concepts of transparency and traceability in fashion supply chains are theoretically defined, also including their significance for sustainable developments. The discussion then focuses on digital tools that can enable greater transparency, especially in the field of product development across footwear and fashion supply chains. In the end, we present a real-world example of introducing a new visibility solution in the footwear industry to foster transparency and traceability developments.

Transparency

In general transparency is considered as one of the first building blocks towards a sustainable transformation of business practices. It enables organizations to gain a comprehensive understanding of their operations, including their strengths and weaknesses. With transparency, businesses can identify inefficiencies and waste, which can then be minimized or eliminated, resulting in more resource-efficient operations. This, in turn, leads to reduced environmental impact and a more sustainable approach.

When it comes to supply chain transparency, a reliable system can play a key role in ensuring that the right measures are taken to mitigate risks and promote sustainable practices along the entire value chain. Having a suitable transparency system in place is therefore essential for identifying and addressing supply chain risks, especially in the context of new regulations such as the German Act on Corporate Due Diligence Obligations in Supply Chains (Lieferkettensorgfaltspflichtengesetz).

Supply Chain Transparency

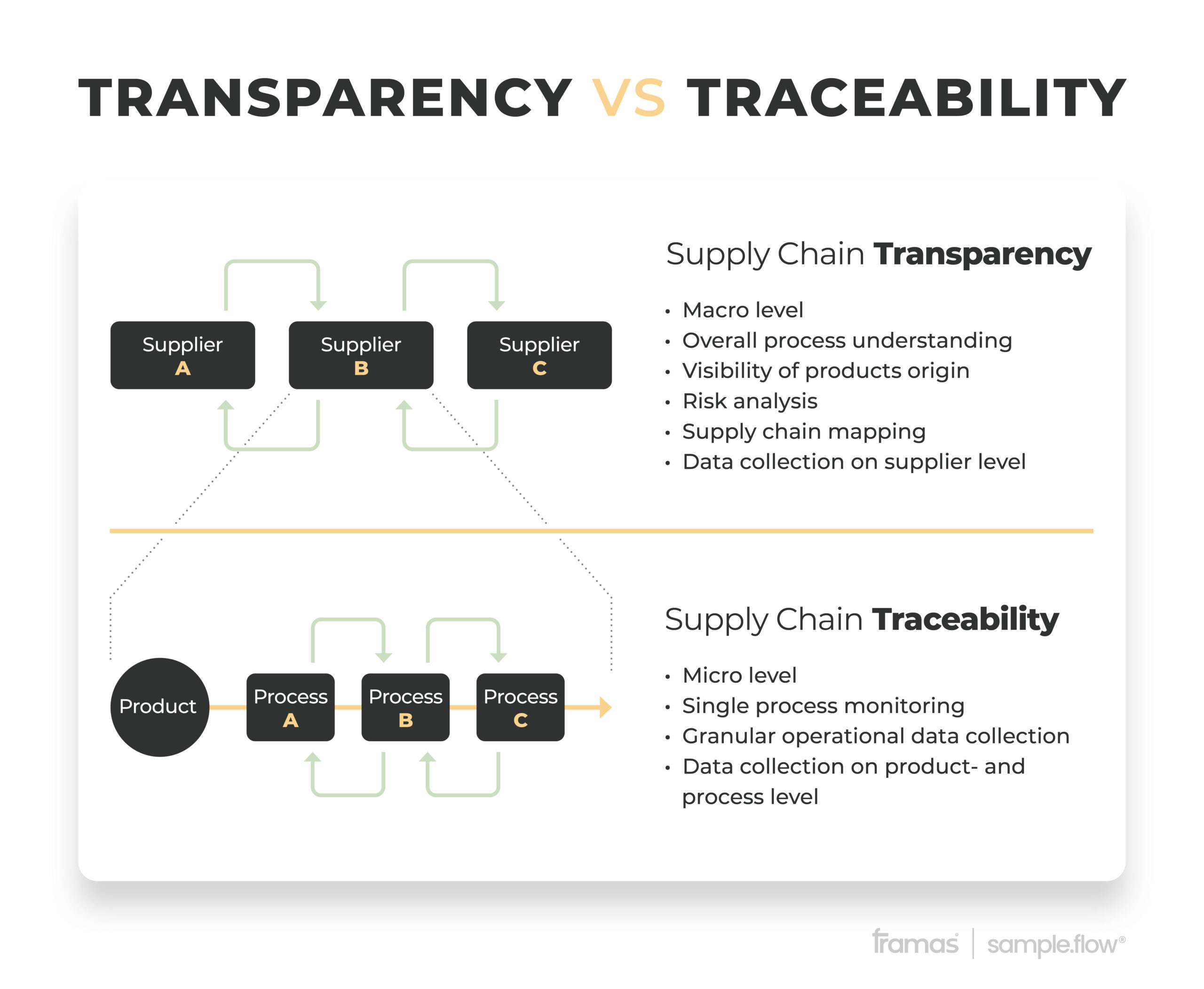

Supply chain transparency can be defined as the company’s understanding of the processes in their supply chain and the communication about it internally and externally. This does also include an increased communication about the product’s origin.

Additionally, transparency can be viewed as a corporate policy that is identifying supply chain risks early on with the aim of implementing continuous improvements with the involved stakeholders. Supply chain transparency refers to gathering and exchanging information at the meta level. This includes for example the collection of supplier data, locations, certificates, and their validity. Which then allows a general visualization of the company’s supply chains, also called supply chain mapping.

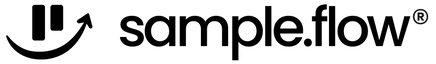

The diffusion theory of innovation can help to determine the degree of a company’s transparency efforts along their own supply chain. Considering their depth of involvement, looking downstream including suppliers and partners until the raw material supply. Companies can be categorized also in regards of their innovation potential in relation to their transparency initiatives.

In summary it can be said that leveraging supply chain transparency enables companies to gain a better visibility of their entire supply network. Therefore, supply chain transparency plays a key role for every company that is striving to take over greater control and responsibility along their own value chains, including the involvement of suppliers and stakeholders.

Traceability of the supply chain

In contrast to the overarching concept of supply chain transparency, the term traceability of the supply chain pertains to more granular insights into the operational procedures within the supply chain. Rather than focusing on the entire mapping of the supply chain, traceability is concerned with the collection of accurate data about a product through each processing stage. This type of data could include order- or batch details, product information such as components and materials, as well as processing and lead times referring to specific processing stages.

Having a proper traceability system in place enables companies to reduce resource waste such as time and manpower, identify quality issue at the spot and reduce supply chain risks. Furthermore, the collection of granular data can provide valuable insights that can be used to generate overall transparency of a specific processing stage. Through the identification of inefficiencies, new opportunities for process improvements and control are given.

To conclude, it can be said that supply chain transparency is primarily related to the visualization of the supply chain, while supply chain traceability pertains to the visualization of granular operational data. Nevertheless, supply chain transparency can be described as a main category, with supply chain traceability being a subcategory.

What can fashion- and footwear companies do to be more transparent?

Companies in the footwear and fashion industry currently face the challenge of finding and implementing suitable IT systems that can promote transparency both at a macro and micro level, encompassing specific processing stages throughout their entire value chain. Only through the application of appropriate systems can risks and inefficiencies be identified and addressed for improvement.

In addition, the importance of Lean Management concepts is increasing, as this method aims to increase productivity, reduce waste, and ultimately minimize lead times and fasten time-to-market. Furthermore, this concept helps to address the rising challenges of skilled labor shortage. Investing in suitable software solutions for the digital transformation of business processes is crucial for footwear- and fashion companies looking to stay competitive in a rapidly digitizing world. By implementing these solutions, businesses can establish a stable and well-positioned presence in the marketplace, with streamlined processes and increased efficiency.

Digitization of framas supply chain

framas is continuously taking steps towards digital transformation, striving to ensure full transparency, and taking over responsibility for a more sustainable future.

Implementing the solution sample.flow® in their product development processes was one big milestone. framas is now tracing e.g., its mold and shoe lasts sampling processes in Germany, Korea and Vietnam with the system, to ensure a waste free and speedy workflow. sample.flow® combines smart RFID scanners with a SaaS software solution, enabling fast and clean data collection at every process step in real-time. Every sample can be easily allocated with its complete status in each step of the sampling process.

Additionally, a live dashboard view summarizes the most important KPIs to monitor our performance and to identify continuous improvement potential. framas now has a suitable system in place that ensures full sampling traceability on the one hand and the delivery of clean data to foster overall transparency developments on the other hand.

Bridging the physical and digital world has allowed framas to reduce their sampling time-to-market by up to 50%, while internal and external communication times have decreased massively.

Benefits

- 100% transparency & traceability: Clear Kanban- and Dashboard Views with real-time sample status data. No more time loss through searching and waiting for samples.

- Up to 50% faster time to market: Reduction of development lead times and improved delivery reliability. Speeding up time to market significantly.

- 30% more focus & productivity: More time for creative things in daily business. Increased productivity through less waste. 43 hours saved per month searching samples (per person).

*This article is created in cooperation with experts from Arkema to provide you a deeper inside into this topic. It is not sponsored or paid in any way.

If you liked this article, make sure to follow our Social Media channels and leave your feedback. You can contact us anytime via LinkedIn, Instagram & Facebook.

We are happy to receive any feedback and tell us what other topics are of interest to you. We will try to address them in the near future.

As well you can contact sample.flow® over their website.

Thanks for checking out our blog!